Gradient porous bone scaffold material and preparation method thereof

A gradient porous, bone scaffolding technology, applied in the fields of medical science, prosthesis, tissue regeneration, etc., can solve the problem that high pore structure and high mechanical properties cannot coexist, and achieve controllable pore structure, good osteogenic activity, and mechanical properties Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) prepare bioactive glass nanopowder and be mixed with suspension;

[0035] (2) respectively dissolving collagen and phosphoserine in glacial acetic acid to prepare a suspension;

[0036] (3) Stir and mix the collagen suspension obtained in step (2) with the phosphoserine suspension;

[0037] (4) Slowly add the bioactive glass suspension obtained in step (1) into the mixed vortex suspension of step (3), mix well, and control the mass ratio of bioactive glass / collagen / phosphoserine to be 65:30: 5. Control the water content of the suspension to obtain a suspension ①, a 60% suspension ②, and a 50% suspension ③ with a water content of 70%.

[0038] (5) The bioactive glass / collagen / phosphoserine gel-like suspension ① prepared in step (4) is injected into the composite scaffold forming mold, and then frozen.

[0039] (6) Take out the mold in step (5), inject the suspension ② on the surface of the solidified suspension, and then freeze; inject the suspension ③ after it sol...

Embodiment 2

[0047] Change the mass ratio of bioactive glass / collagen / phosphoserine in Example 1 to 65:32:3, and control the water content of the suspension to 75%, 65%, and 55%, respectively. The other steps were the same as in Example 1 to prepare a gradient porous bioactive glass / collagen / phosphoserine composite scaffold.

Embodiment 3

[0049] Change the mass ratio of bioactive glass / collagen / phosphoserine in Example 1 to 65:34:1, and control the water content of the suspension to 80%, 70%, and 60%, respectively. The other steps were the same as in Example 1 to prepare a gradient porous bioactive glass / collagen / phosphoserine composite scaffold.

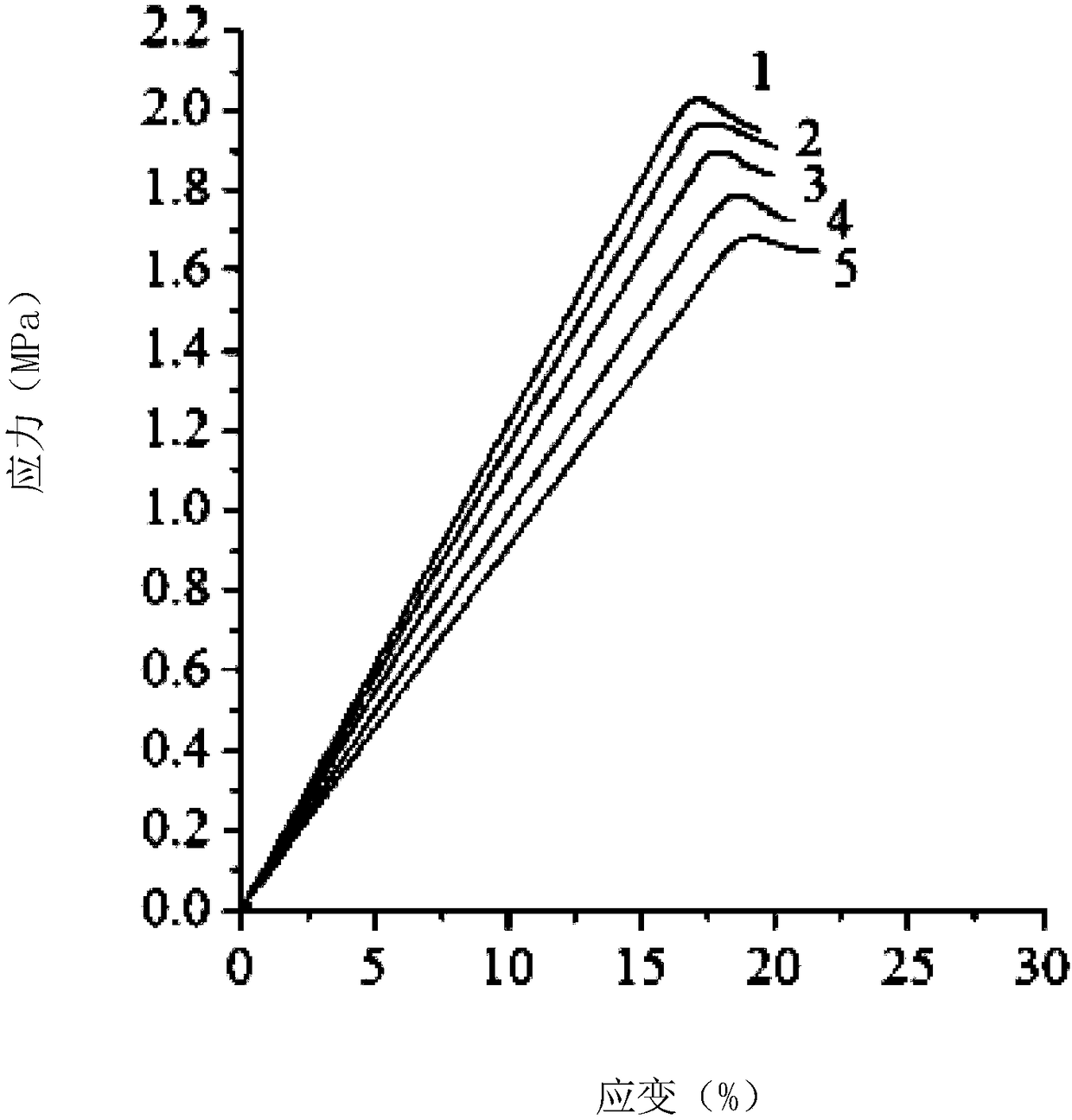

[0050] The compressive strength of the material was tested using a universal testing machine. Such as figure 2 As shown, it can be seen from the curves that all scaffolds go through several stages: linear elastic deformation under small stress, followed by short-term flexural deformation, and finally rapid fracture. Moreover, as the bioglass content increased from 60% to 70%, the ultimate strength and elastic modulus before fracture of the scaffold also increased, indicating that the composition of the scaffold had a significant impact on its mechanical strength. The higher the water content of the suspension, the higher the porosity, which allows the scaffold to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com