Preparation method of carbon excited slag brick

A technology of steel slag bricks and steel slag, which is applied in the field of preparation of carbon-activated steel slag bricks, can solve the problems of large volume expansion rate, consumption, poor stability, etc., and achieve good performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

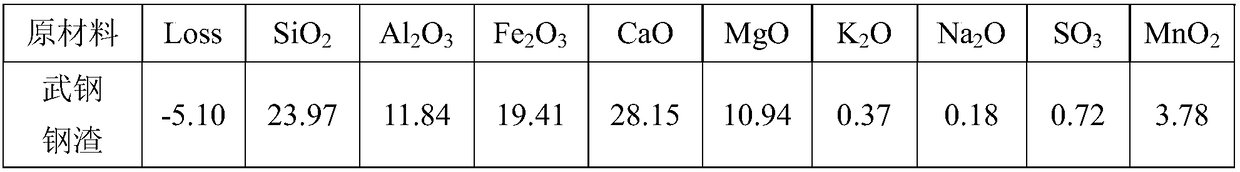

[0032] The steel slag used in this embodiment is WISCO steel slag, and its main components and content (wt%) are as shown in the following table:

[0033] Table 1 Chemical composition of steel slag

[0034]

[0035] After the steel slag is crushed, iron-selected and ground, the iron content is lower than 2%, and the particle size is about 0-5mm. Select the steel slag fine particles with a particle size of 4.75 mm to 1.18 mm for use. After infrared particle size analysis and detection, the content of the steel slag fine particles with a particle size of 4.75 mm to 1.18 mm is greater than 85%, and the particles exceeding 4.75 mm are not More than 5%. The above steel slag particles are dried and ground by a ball mill to obtain a particle size of 1 μm-100 μm and a Blaine specific surface area of 220-420m 2 / kg of steel slag powder. The Blaine specific surface area is measured according to the method in the national standard "Method for Determination of Cement Specific Surf...

Embodiment 2

[0041] Utilize steel slag from the same source as in Example 1 to prepare steel slag fine particles with a particle size of 2.36 mm to 0.6 mm, and a particle size of 1 to 100 μm and a Blaine specific surface area of 220 to 420 m 2 / kg of steel slag powder. The particle size distribution requirements of steel slag fine particles and steel slag fine powder remain unchanged.

[0042] Utilize above-mentioned steel slag to prepare the method for carbon excited steel slag brick as follows:

[0043] 1) Mixing: Take 138.1 parts of the above steel slag micropowder, 63.8 parts of fly ash, 37.5 parts of phosphogypsum (dihydrate gypsum), 10.6 parts of sodium sulfate, and 1200 parts of steel slag fine particles, and mix them in a mixer for 0.5-1min;

[0044] 2) Blank making: add 37.5 parts of water to the mixture obtained in step (1), stir for 1-2 minutes, then add 37.5 parts of water and stir for 2-3 minutes, and finally pour the mixture into a brick-making mold to form a steel slag br...

Embodiment 3

[0047] Steel slag from the same source as in Example 1 was used to prepare steel slag fine particles with a particle size of 4.75mm-1.18mm and 1.18mm-0.6mm, and a particle size of 1-100 μm and a Blaine specific surface area of 220-420m 2 / kg of steel slag powder. The particle size distribution requirements of steel slag fine particles and steel slag fine powder remain unchanged.

[0048] Utilize above-mentioned steel slag to prepare the method for carbon excited steel slag brick as follows:

[0049] 1) Mixing: Take 120.8 parts of the above-mentioned steel slag fine powder, 52.5 parts of silica fume, 75 parts of phosphogypsum (dihydrate gypsum), 1.7 parts of sodium sulfate, and 600 parts of fine steel slag particles with a particle size of 4.75 mm to 1.18 mm, with a particle size of 1.18 mm. 600 parts of steel slag fine particles of mm ~ 0.6mm, placed in a mixer and mixed for 0.5-1min;

[0050] 2) Blank making: add 40 parts of water to the mixture obtained in step (1), stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com