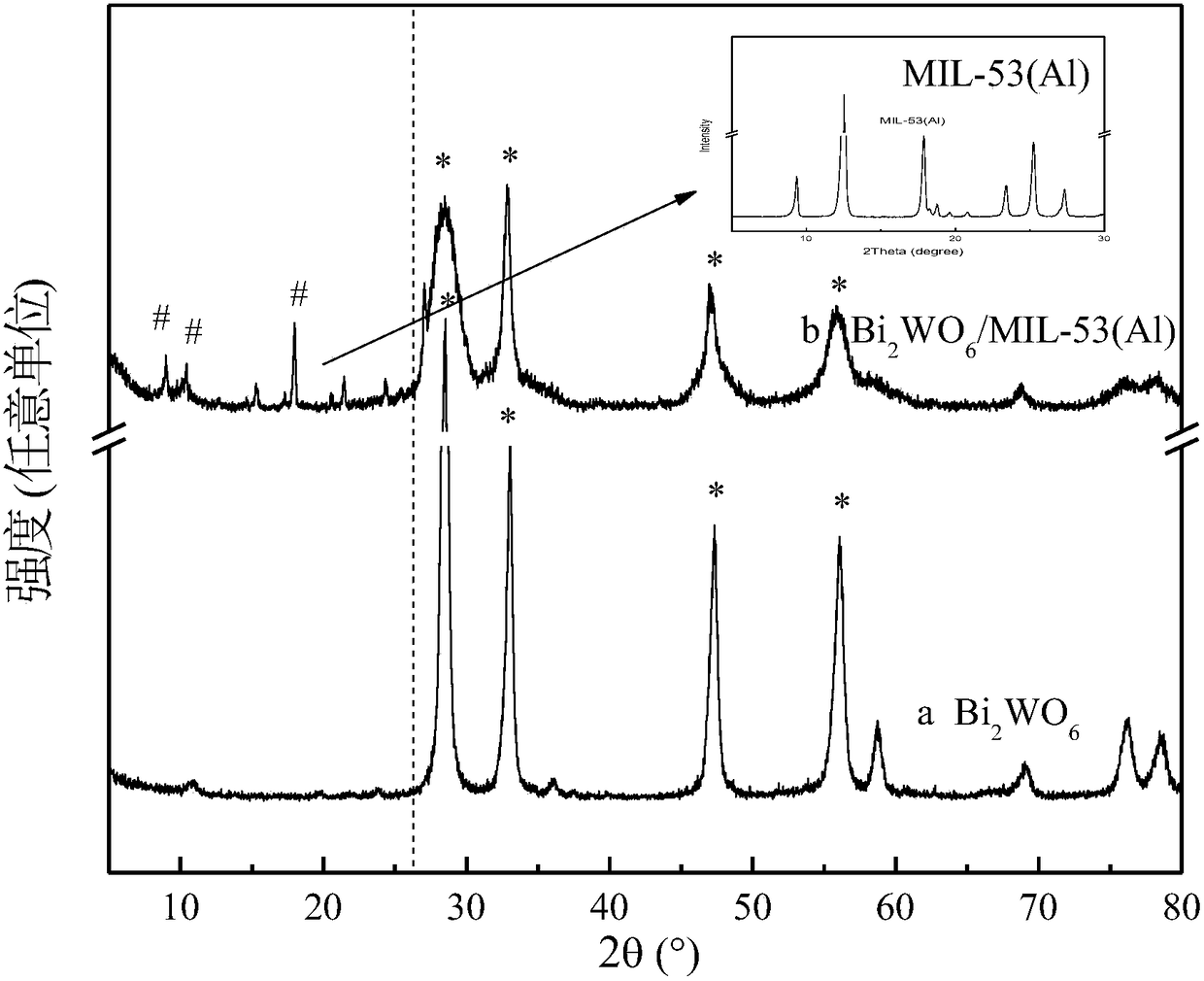

Bismuth tungstate-MIL-53 (Al) composite material and preparation method and application thereof

A MIL-53 and composite material technology, applied in chemical instruments and methods, catalyst activation/preparation, water treatment of special compounds, etc., to achieve significant industrial application value, expand the absorption range, and change the effect of microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In this example,

[0031] A preparation method of bismuth tungstate-MIL-53 (Al) composite material, comprising the steps of:

[0032] (1) Weigh 0.07mol of Al(NO 3 ) 3 9H 2 O, 0.035mol of terephthalic acid (H 2 BDC), Al(NO 3 ) 3 9H 2 O and H 2 BDC was dissolved in 100mL of distilled water, treated by ultrasonic dispersion for 30min, mixed uniformly and fully dissolved to obtain mixed solution A, and then the mixed solution A was transferred to an autoclave by solvothermal method, and then the autoclave was placed in a temperature of 220 In an oven at ℃, the reaction was carried out for 72 hours. After the reaction product was cooled to room temperature, it was centrifuged, washed twice with twice distilled water and washed once with absolute ethanol to obtain a pure reaction product, and then placed in an oven at a temperature of 80℃ , the reaction product was vacuum-dried for 10 hours to obtain the product MIL-53(Al), which was used as a carrier material for sub...

Embodiment 2

[0039] This embodiment is basically the same as Embodiment 1, especially in that:

[0040] In the present embodiment, a kind of preparation method of bismuth tungstate-MIL-53 (Al) composite material, comprises the steps:

[0041] (1) This step is identical with embodiment one;

[0042] (2) This step is identical with embodiment one;

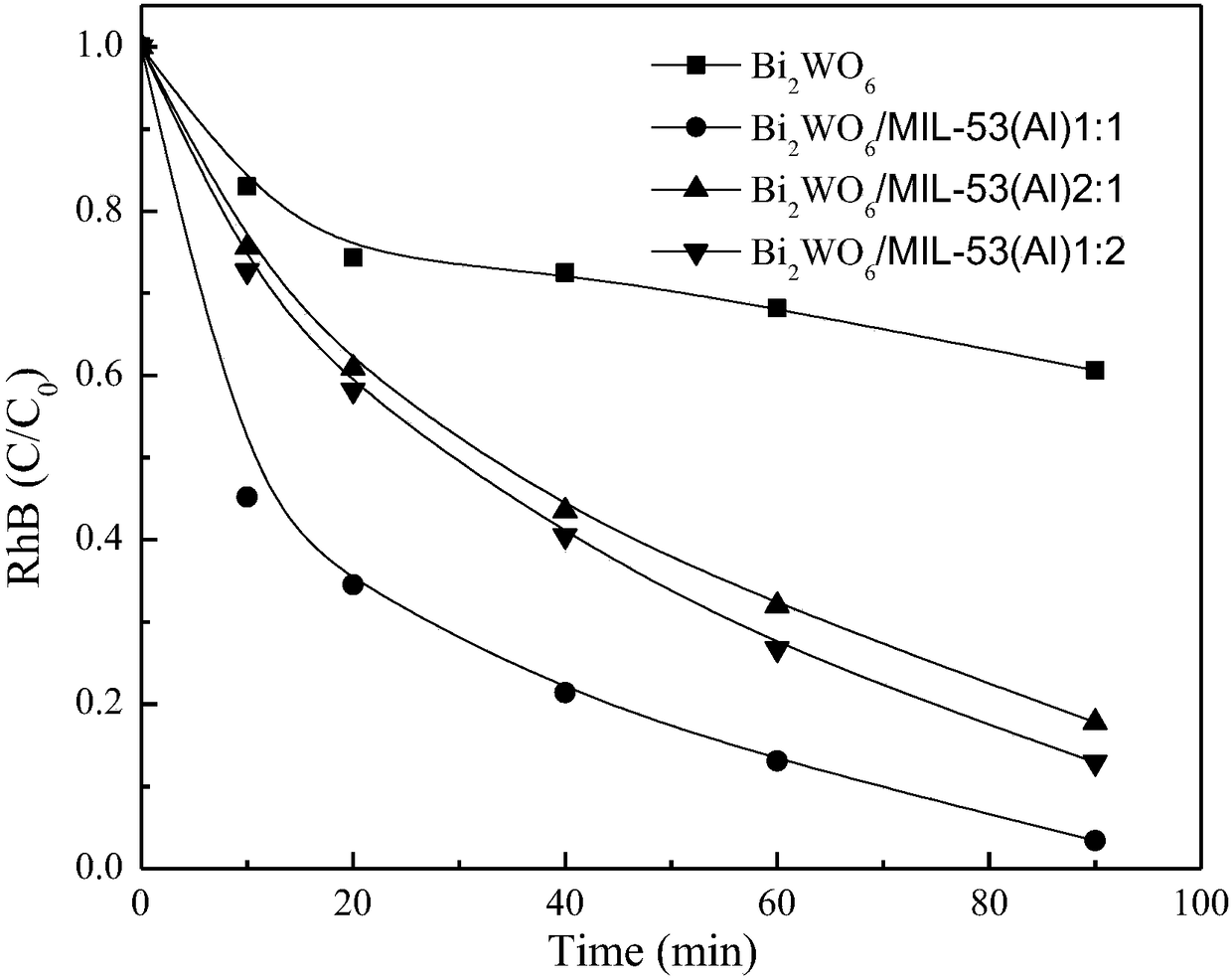

[0043] (3) Weigh 1mmol of Na respectively 2 WO 4 2H 2Cetyltrimethylammonium bromide (CTAB) of O, 0.2g and the MIL-53 (Al) that 0.5mmol makes in above-mentioned step (1), Na 2 WO 4 2H 2 Dissolve O and cetyltrimethylammonium bromide together in 20mL ethylene glycol solution to obtain sodium tungstate solution, then mix MIL-53(Al) and sodium tungstate solution evenly, and use ultrasonic dispersion treatment 30min, and under agitation, the above-mentioned mixed solution was added dropwise to the Bi(NO 3 ) 3 solution, and NaOH solution was added to the mixed solution to adjust the pH of the mixed solution to 4, and then the mixed solution was...

Embodiment 3

[0047] This embodiment is basically the same as the previous embodiment, and the special features are:

[0048] In the present embodiment, a kind of preparation method of bismuth tungstate-MIL-53 (Al) composite material, comprises the steps:

[0049] (1) This step is identical with embodiment one;

[0050] (2) This step is identical with embodiment one;

[0051] (3) Weigh 1mmol of Na respectively 2 WO 4 2H 2 Cetyltrimethylammonium bromide (CTAB) of O, 0.2g and the MIL-53 (Al) that 2mmol makes in above-mentioned step (1), Na 2 WO 4 2H 2 Dissolve O and cetyltrimethylammonium bromide together in 20mL ethylene glycol solution to obtain sodium tungstate solution, then mix MIL-53(Al) and sodium tungstate solution evenly, and use ultrasonic dispersion treatment 30min, and under agitation, the above-mentioned mixed solution was added dropwise to the Bi(NO 3 ) 3 solution, and NaOH solution was added to the mixed solution to adjust the pH of the mixed solution to 4, and then th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com