Method for separating electrolytic manganese anode mud to produce electrolytic manganese metal and recovering lead

A technology of electrolytic manganese metal and anode slime, which is applied to the improvement of process efficiency, photography technology, instruments, etc., can solve the problems of high production cost, damage to people's life and health, and long process route, so as to improve efficiency and quality, and realize waste Reuse, quick effect of processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

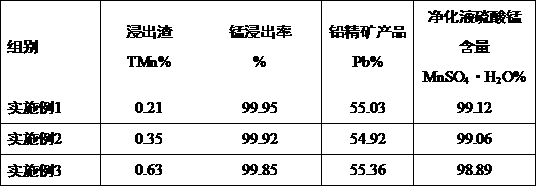

Embodiment 1

[0026] A method for separating electrolytic manganese anode slime to produce electrolytic metal manganese and recovering lead, comprising the following steps:

[0027] S1. Electrolytic manganese anode slime and 3.5mol L -1 sulfuric acid solution, and add 70 g·L -1 Stir the waste molasses aqueous solution, the amount of waste molasses is 90% of the theoretical amount of reducing agent, and the stirring speed is 200 r min -1 , in the above-mentioned mixture of electrolytic manganese anode slime, sulfuric acid solution and waste molasses aqueous solution, the liquid-solid ratio is 4:1, the temperature of the mixture is maintained at 70°C, reacted for 40min, and then add iron powder, the consumption of iron powder is greater than that of the remaining reducing agent Theoretical dosage, react for 15 minutes, after the reaction is completed, use a filter press to separate the leachate and leach residue;

[0028] S2. Add H to the leaching solution 2 o 2 , the oxidation condition ...

Embodiment 2

[0032] A method for separating electrolytic manganese anode slime to produce electrolytic metal manganese and recovering lead, comprising the following steps:

[0033] S1. Electrolytic manganese anode slime and 3.5mol L -1 sulfuric acid solution, and add 65 g·L -1 Stir the waste molasses aqueous solution, the amount of waste molasses is 90% of the theoretical amount of reducing agent, and the stirring speed is 150 r min -1 , in the above-mentioned mixture of electrolytic manganese anode slime, sulfuric acid solution and waste molasses aqueous solution, the liquid-solid ratio is 4.2:1, the temperature of the mixture is kept at 75°C, reacted for 50min, and then adds iron powder, the consumption of iron powder is greater than that of the remaining reducing agent Theoretical dosage, react for 10 minutes, after the reaction is completed, use a filter press to separate the leachate and leach residue;

[0034] S2. Add H to the leaching solution 2 o 2 , the oxidation condition is:...

Embodiment 3

[0038] A method for separating electrolytic manganese anode slime to produce electrolytic metal manganese and recovering lead, comprising the following steps:

[0039] S1. Electrolytic manganese anode slime and 3.5mol L -1 sulfuric acid solution, and add 70 g·L -1 Stir the waste molasses aqueous solution, the amount of waste molasses is 85% of the theoretical amount of reducing agent, and the stirring speed is 250 r min -1, in the above-mentioned mixture of electrolytic manganese anode slime, sulfuric acid solution and waste molasses aqueous solution, the liquid-solid ratio is 3.8:1, the temperature of the mixture is maintained at 80°C, reacted for 30min, and then add iron powder, the consumption of iron powder is greater than that of the remaining reducing agent Theoretical dosage, react for 20 minutes, after the reaction is completed, use a filter press to separate the leaching solution and leaching residue, and the leaching residue is cleaned in the filter press and then t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com