Technology for preparing light-weight ceramsite by taking basalt tailings as main material

A lightweight ceramsite and basalt technology, applied in the production of ceramic products, clay products, ceramic materials, etc., can solve the problems of high storage cost and large amount of superplastic clay, achieve simple production process, reduce storage cost, and widely distribute Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

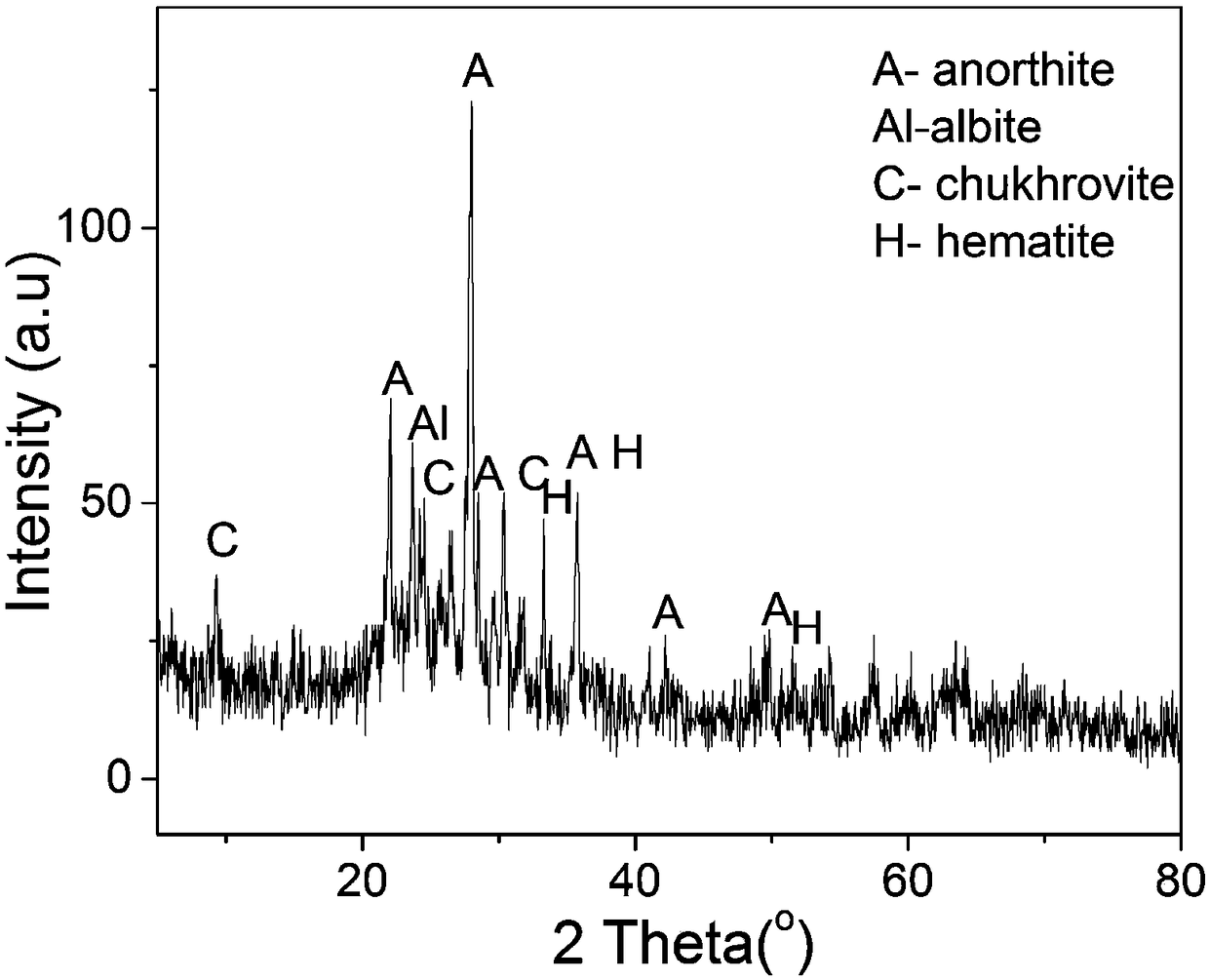

Image

Examples

Embodiment 1

[0033] The present embodiment prepares lightweight ceramsite according to the following steps:

[0034] The first step, the preparation phase:

[0035] Use the jaw crusher and disc mill in turn to crush and grind the large-grain basalt tailings, fly ash extraction aluminate slag, superplastic clay and oil shale semi-coke raw meal, and then pass through a 150-mesh sieve , to obtain basalt tailings powder, fly ash extracted alumina slag powder, superplastic clay powder and oil shale semi-coke powder;

[0036] The second step, mixing:

[0037] Mix basalt tailings powder, fly ash aluminate slag powder, superplastic clay powder and oil shale semi-coke powder at a mass ratio of 5:2:2:1, then add water and stir evenly, the gray-to-water ratio is about 2.1 , get the mixture;

[0038] The third step, molding:

[0039] Put the mixture into a granulator for molding, and put the obtained sample into a blast drying oven at 105°C to dry to constant weight to obtain mixture granules;

...

Embodiment 2

[0044] In this example, light-weight ceramsite was prepared by the same method as in Example 1, except that the temperature of secondary sintering in the fourth step was 1150°C.

Embodiment 3

[0046] In this example, lightweight ceramsite was prepared by the same method as in Example 1, except that the temperature of the secondary sintering in the fourth step was 1200°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com