Modified X-type molecular sieve with low silica-alumina ratio, and preparation method and application thereof

A low-silicon-aluminum ratio, molecular sieve technology, applied in molecular sieves and alkali exchange compounds, separation methods, aluminum silicate and other directions, can solve the problems of high and low temperature rectification methods with energy consumption, reduce energy consumption, increase Ar adsorption capacity, The effect that is conducive to the sustainable development of the economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

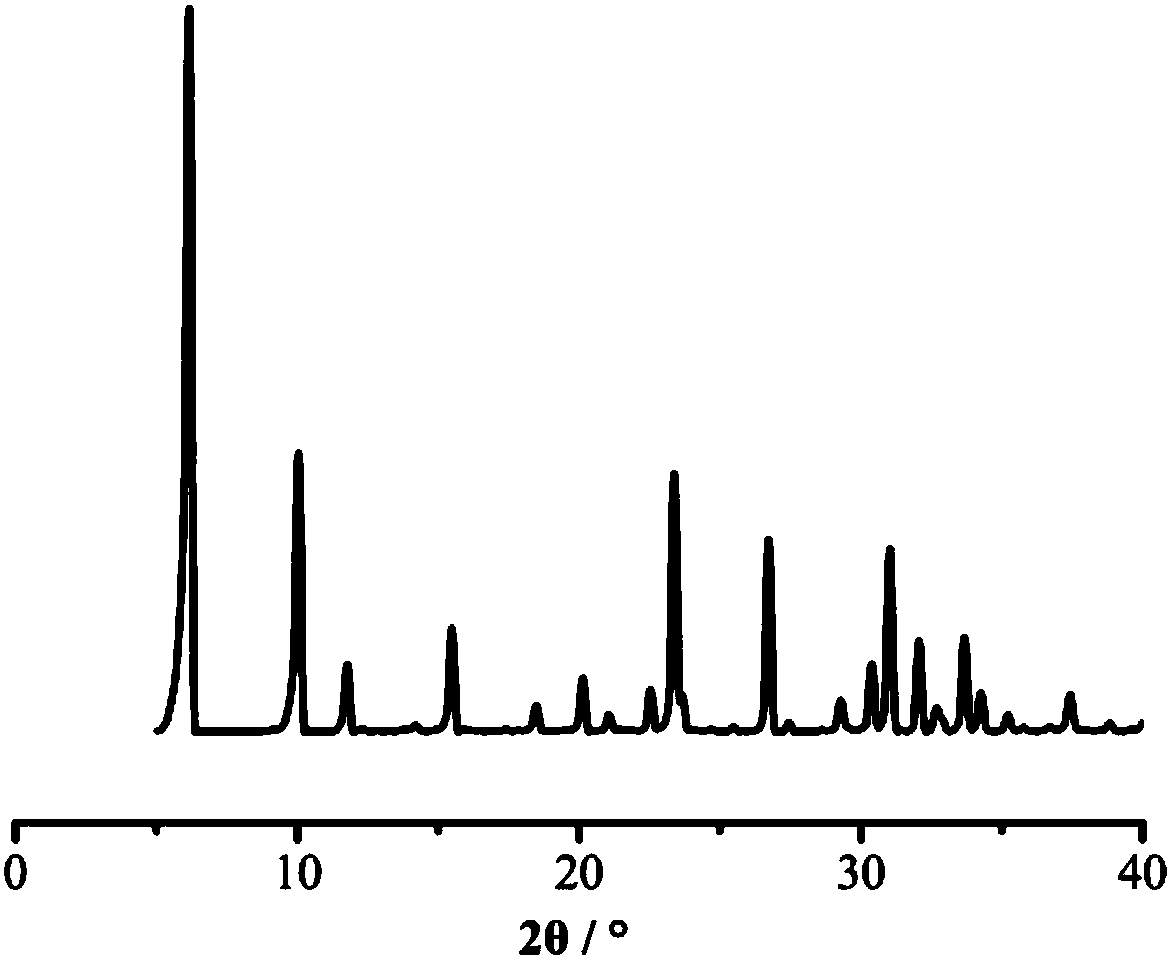

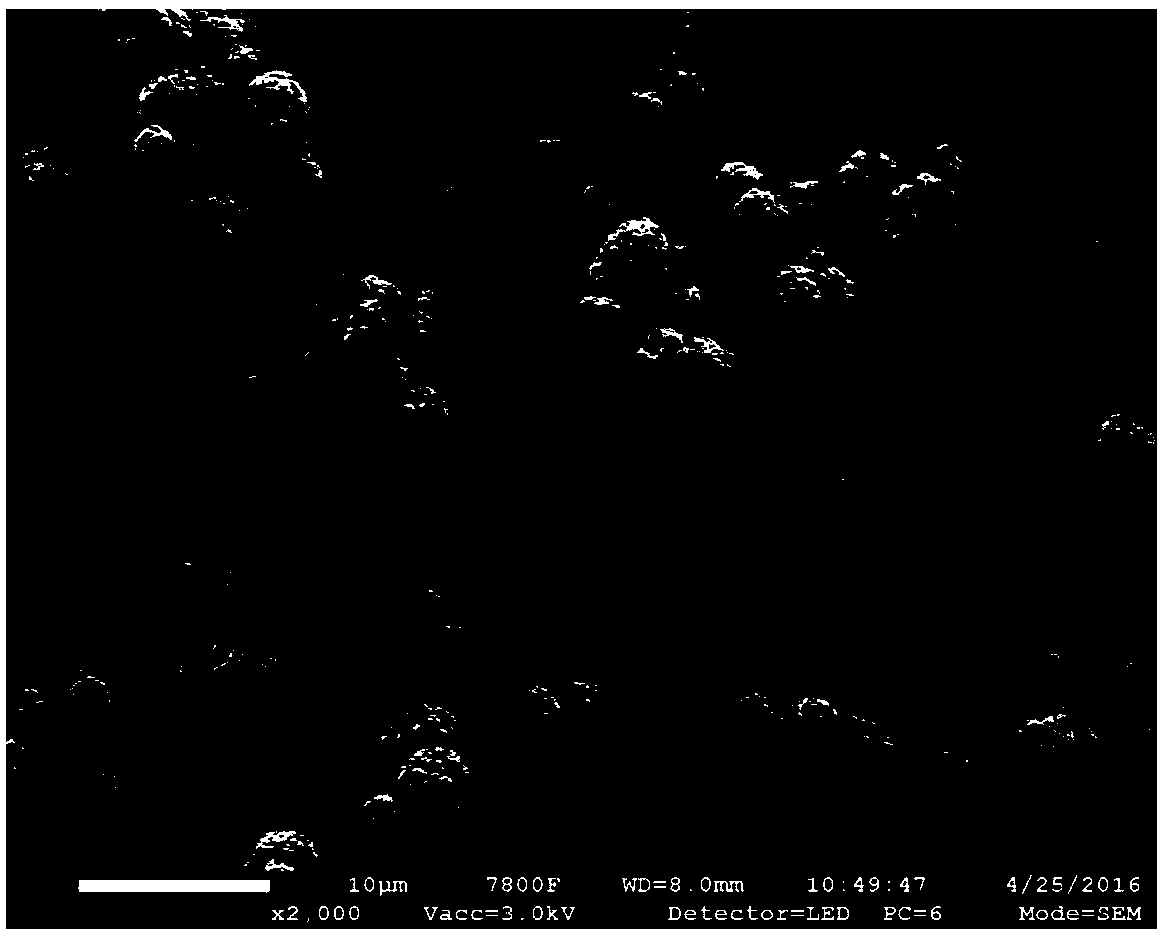

[0036] (1) 31.4g NaAlO 2 Dissolved in 340.5 g deionized water, 68.5 g NaOH and 35.4 g KOH were added while stirring. Stir until the solid is completely dissolved and cool to room temperature, slowly add 84.2 g of silica sol with a mass fraction of 30% under rapid stirring, and continue stirring for 1 hour. The mixed solution was transferred to a three-necked flask, and placed in a water bath with a set temperature of 85° C. and mechanically stirred for 24 hours. After the reaction was completed, the temperature was naturally lowered to room temperature, and the solid product was separated by vacuum filtration, and washed with a large amount of deionized water until the pH of the filtrate was less than 8. The product was dried at 100° C. for 12 hours to obtain a white powder.

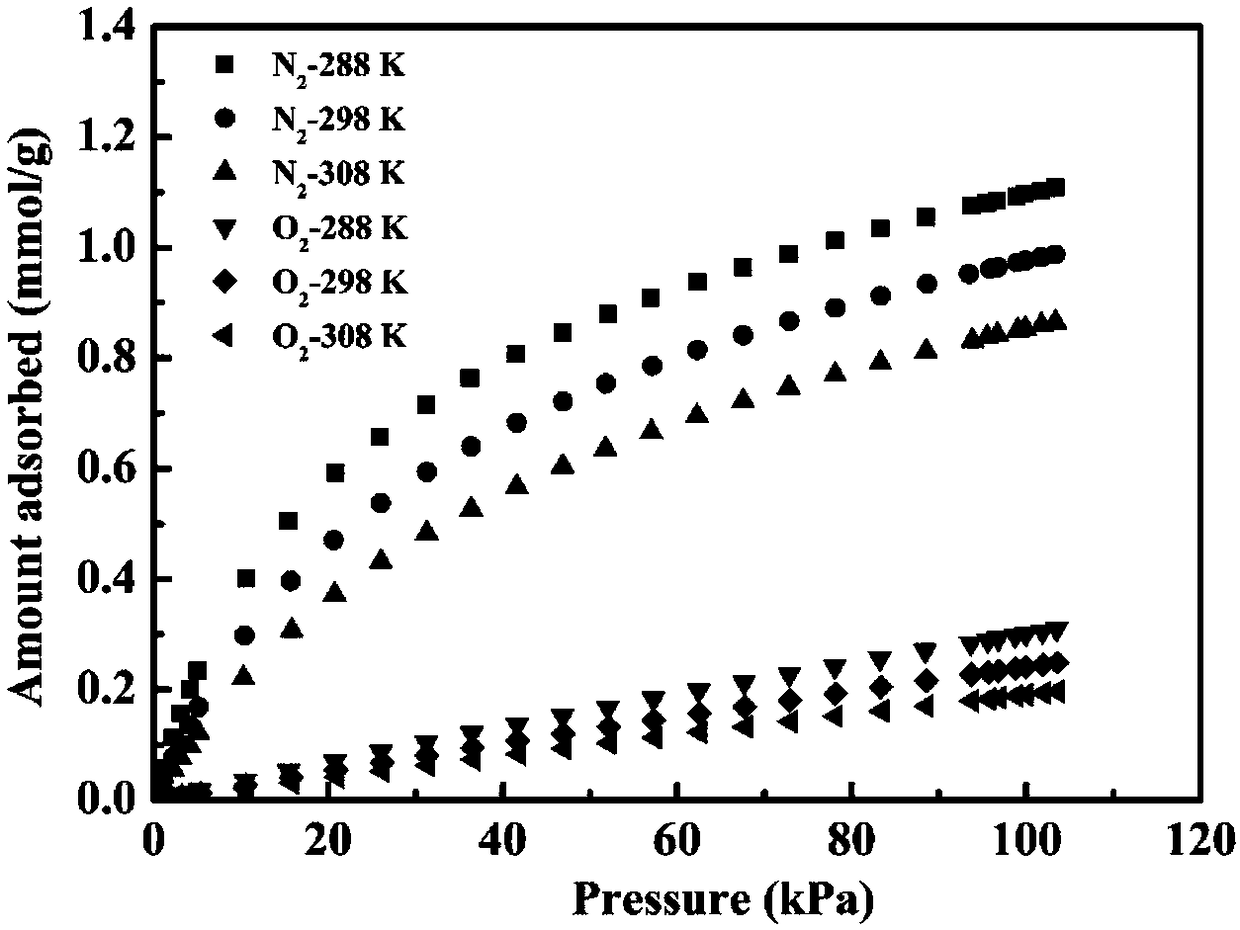

[0037] (2) Weigh 1g of molecular sieve raw powder into a round bottom flask, add 17ml of 1mol / L FeCl 3 The solution was ion-exchanged under the conditions of heating in a water bath at 85° C. and magn...

Embodiment 2

[0040] (1) 31.4g NaAlO 2 Dissolved in 340.5 g deionized water, 68.5 g NaOH and 35.4 g KOH were added while stirring. Stir until the solid is completely dissolved and cool to room temperature, slowly add 84.2 g of silica sol with a mass fraction of 30% under rapid stirring, and continue stirring for 1 hour. The mixed solution was transferred to a three-necked flask, and placed in a water bath with a set temperature of 85° C. and mechanically stirred for 24 hours. After the reaction was completed, it was naturally cooled to room temperature, and the solid product was separated by vacuum filtration, and washed with a large amount of deionized water until the pH of the filtrate was less than 8. The product was dried at 100° C. for 12 hours to obtain a white powder.

[0041] (2) Weigh 1g of molecular sieve raw powder into a round bottom flask, add 20ml of 0.5mol / L LaCl 3 and CeCl 3 The mixed solution was ion-exchanged under the conditions of heating in a water bath at 85° C. an...

Embodiment 3

[0044] (1) 31.4g NaAlO 2 Dissolved in 340.5 g deionized water, 68.5 g NaOH and 47.1 g KCl were added while stirring. Stir until the solid is completely dissolved and cool to room temperature, slowly add 84.2 g of silica sol with a mass fraction of 30% under rapid stirring, and continue stirring for 1 hour. The mixed solution was transferred to a three-necked flask, and placed in a water bath with a set temperature of 85° C. and mechanically stirred for 24 hours. After the reaction was completed, it was naturally cooled to room temperature, and the solid product was separated by vacuum filtration, and washed with a large amount of deionized water until the pH of the filtrate was less than 8. The product was dried at 100° C. for 12 hours to obtain a white powder.

[0045] (2) Weigh 1g of molecular sieve raw powder into a round bottom flask, add 17ml of 1mol / L CaCl 2 The solution was ion-exchanged under the conditions of heating in a water bath at 85° C. and magnetic stirring,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com