Nuclear test specimen automatic separation device

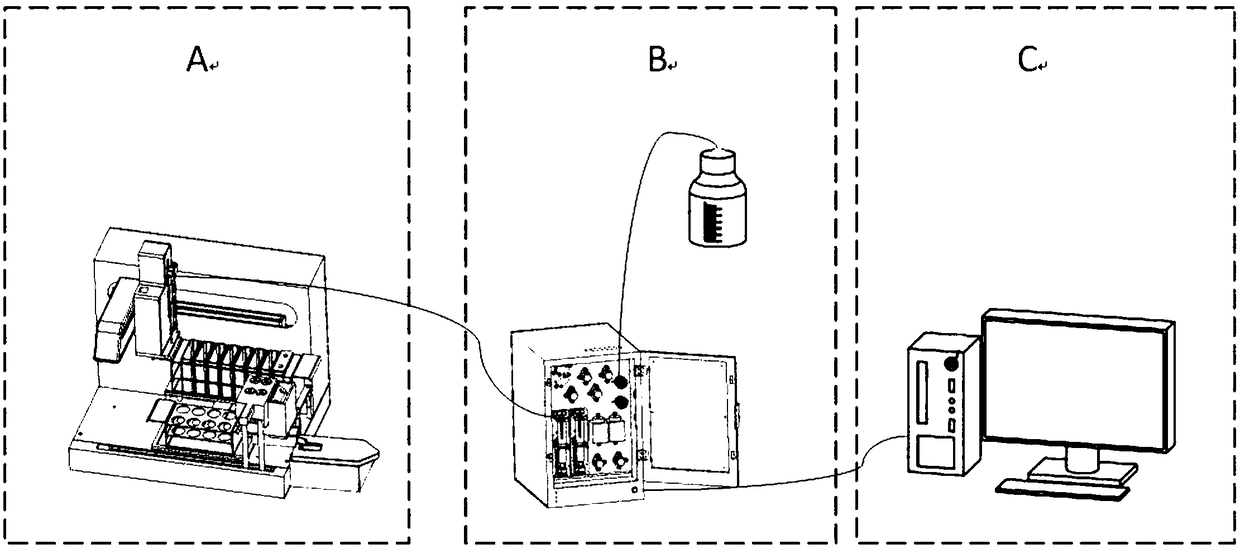

An automatic separation and separation column technology, applied in separation methods, preparation of samples for testing, liquid separation of solid adsorbents, etc., can solve the problems of long sample separation time, short instrument life, long reagent flow time, etc., to avoid crossover. Risk of contamination, improving the accuracy of liquid extraction, and reducing the effect of separation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] In this example, the above-mentioned experimental equipment and collection mode 1 were used for experimental operation, and the specific parameters were: the sample contained 61g / L U, 1.0×10 -4 g / L Np, 4×10 -7 g / L Pu and 3mol / LHNO 3 , the reagent is HNO 3 、HON 3 -HF and H 2 C 2 o 4 、H 2 O. The specific steps are as follows:

[0081] (1) Take 1ml of sample, add 0.2ml ferrous sulfamate reducing agent and put it into the sample bottle, place the sample bottle on the sample bottle holder;

[0082] (2) Turn on the device, start the separation software, and the software running program is:

[0083] aPretreatment with 5ml HNO 3 Add to the extraction column 1 at a flow rate of 1mi / min, and wait for 4 seconds;

[0084] b. Loading Add 2ml of sample into the extraction column 1 at a flow rate of 1ml / min, and wait for 4 seconds;

[0085] c rinse with 10ml HNO 3 Add to the extraction column 1 at a flow rate of 1ml / min, and wait for 4 seconds;

[0086] dElute with 10ml H...

Embodiment 2

[0099] In this embodiment, the above-mentioned experimental equipment and collection mode 3 are used for experimental operation. The specific parameters are: the sample is 16.2ng / ml plutonium solution (3M nitric acid system), and the reagent is HNO 3 、HON 3 -HF and H 2 O. Specific steps are as follows:

[0100] (1) Take 0.3ml of sample in a 5ml sample bottle, add 0.1ml of 0.5M ferrous sulfamate, shake slightly evenly, and place it in the sample position of the sample bottle holder;

[0101] (2) Turn on the device, start the separation software, and the software running program is:

[0102] aPretreatment with 5ml HNO 3 Add to the extraction column 1 at a flow rate of 1mi / min, and wait for 4 seconds;

[0103] b. Loading Add 2ml of sample into the extraction column 1 at a flow rate of 1ml / min, and wait for 4 seconds;

[0104] c Elution with 1ml HNO 3 - HF is added to the extraction column 1 at a flow rate of 1ml / min, the collection tube is at position 1, and wait for 4 sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com