Liquid level detecting device for active immunity workstation

A liquid level detection and workstation technology, applied in analytical materials, instruments, etc., can solve the problems of high maintenance cost, affect the test results, and high cost of consumables, and achieve the effect of reducing the cost of consumables, avoiding cross-contamination, and improving sampling accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

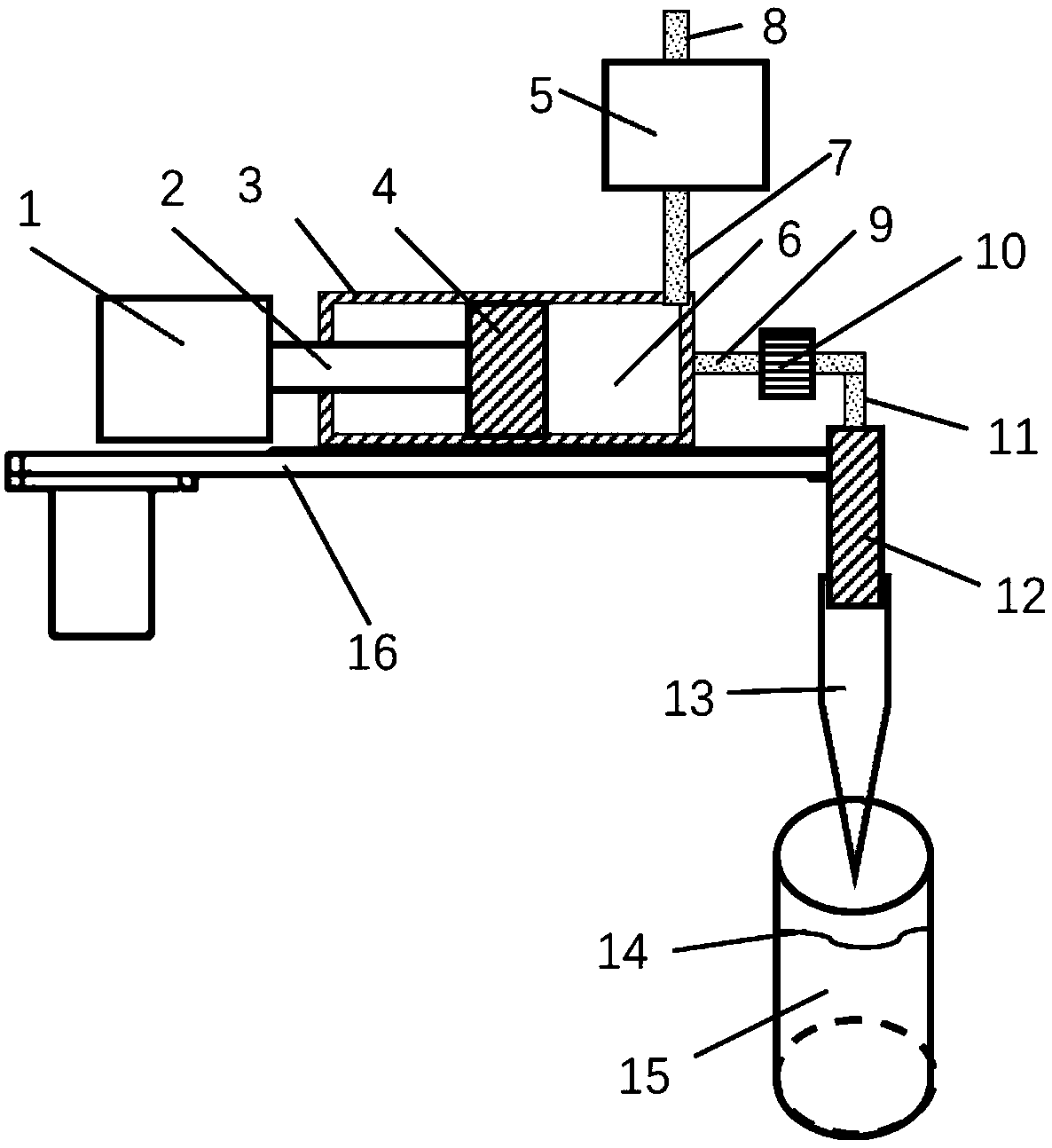

[0014] Such as figure 1 As shown, 1 stepper motor; 2 linear transmission mechanism; 3 plunger pump chamber; 4 plunger pump rubber plug; 5 solenoid valve; 6 plunger pump airtight chamber; Connection with the solenoid valve; 8. Connect the hose to realize the connection between the solenoid valve and the air; 9. Connect the hose to realize the connection between the closed cavity of the plunger pump and the pressure sensor; 10. The pressure sensor; 11. Connect the hose to realize the pressure sensor The communication with the connection mechanism of the sampling head; 12 the connection mechanism of the sampling head; 13 the disposable sampling head; 14 the sample to be tested; 15 the sample tube; 16 the beam of the sampling arm.

[0015] The present invention can be used for a liquid level detection mechanism for detecting the liquid level, a liquid path cleaning mechanism f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com