Excitation method of superconducting coil and excitation method thereof

A technology of superconducting coils and excitation methods, applied in the direction of superconducting magnets/coils, magnetic objects, electrical components, etc., can solve the problems of high price, large heat leakage, unstable current, etc., achieve low cost, avoid expensive, The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

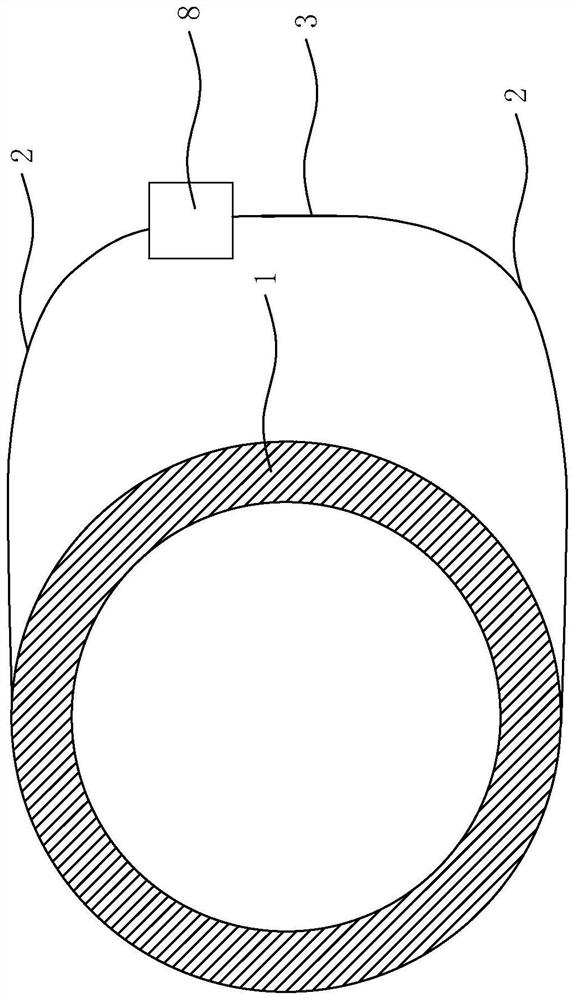

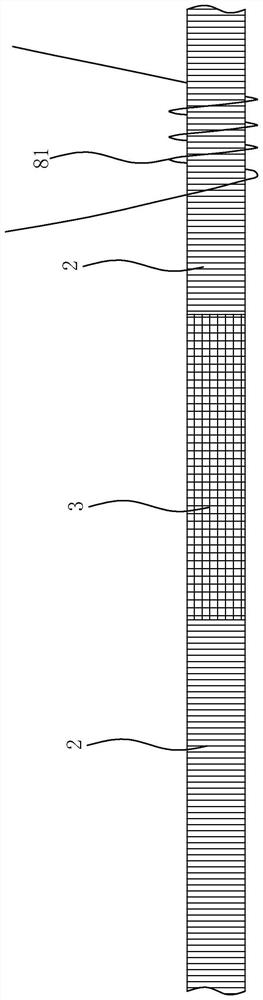

[0034] like figure 1 and Picture 1-1 As shown, the superconducting coil includes a superconducting coil body 1 and a temperature control device 8 . The superconducting coil body 1 is formed by winding a first superconducting tape 2 . More specifically, the first superconducting tape 2 is a BSCCO tape with a width of 4 mm, and the superconducting coil body 1 is a single-wire double-cake coil. The head and tail of the first superconducting strip 2 are pulled out and welded together to form a first joint 3. The solder used for welding is solder, and the wide surface of the first superconducting strip 2 is a superconducting surface. The broad sides of a superconducting strip 2 are welded together. The temperature control device 8 includes a resistance wire 81 wound on the first superconducting tape 2 on the side of the first joint 3, an insulating device arranged between the resistance wire 81 and the first superconducting tape 2, and a resistance wire 81. Wire 81 is connected...

Embodiment 2

[0037] The difference between this embodiment and the first embodiment is:

[0038] Temperature control devices are provided on the first superconducting strips on both sides of the first joint. The temperature control device is the same as the temperature control device in the first embodiment, and can more flexibly control the first superconducting strips on both sides of the first joint. The temperature difference of the conduction strip, thereby flexibly controlling the generated current.

[0039] Other contents of this embodiment are the same as those of the first embodiment, and are not repeated here.

Embodiment 3

[0041] The difference between this embodiment and the second embodiment is:

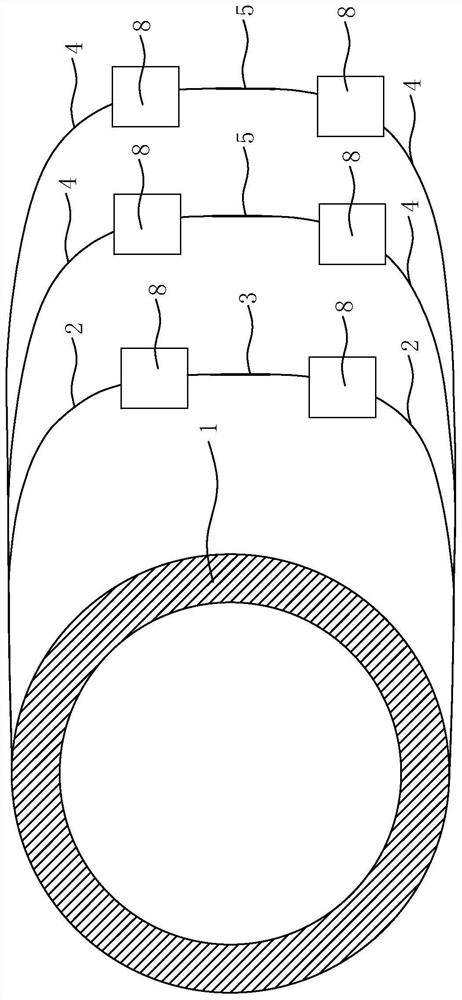

[0042] like figure 2 As shown, it also includes two pairs of second superconducting strips 4 and four temperature control devices 8. The second superconducting strips 4 are also BSCCO strips with a width of 4 mm, and one end of each pair of second superconducting strips 4 is welded to each other. Together, two second joints 5 spaced from the inside to the outside are formed, the other ends of each pair of second superconducting strips 4 are stacked and welded together from the inside to the outside in turn, and the other end of the innermost second superconducting strip 4 It is welded on the superconducting coil body 1 to realize the first joint 3 and the two second joints 5 in parallel. The second superconducting strips 4 on both sides of each second joint 5 are provided with temperature control devices 8 .

[0043] Other contents of this embodiment are the same as those of the second embodiment, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com