Super-strong explosion-proof impact-resistant composite coating and preparation method thereof

A composite coating and impact-resistant technology, applied in the field of coatings, can solve the problems of poor dispersion of fillers, difficulty in dispersing graphene, and difficulty in reaching the ideal level, so as to achieve excellent tensile strength and avoid expensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1.1) Composition of A component and B component of flexible coating material

[0048] A component:

[0049] MDI50 59kg;

[0050] Polytetrahydrofuran ether glycol (PTMG-1000) 41kg;

[0051] B component:

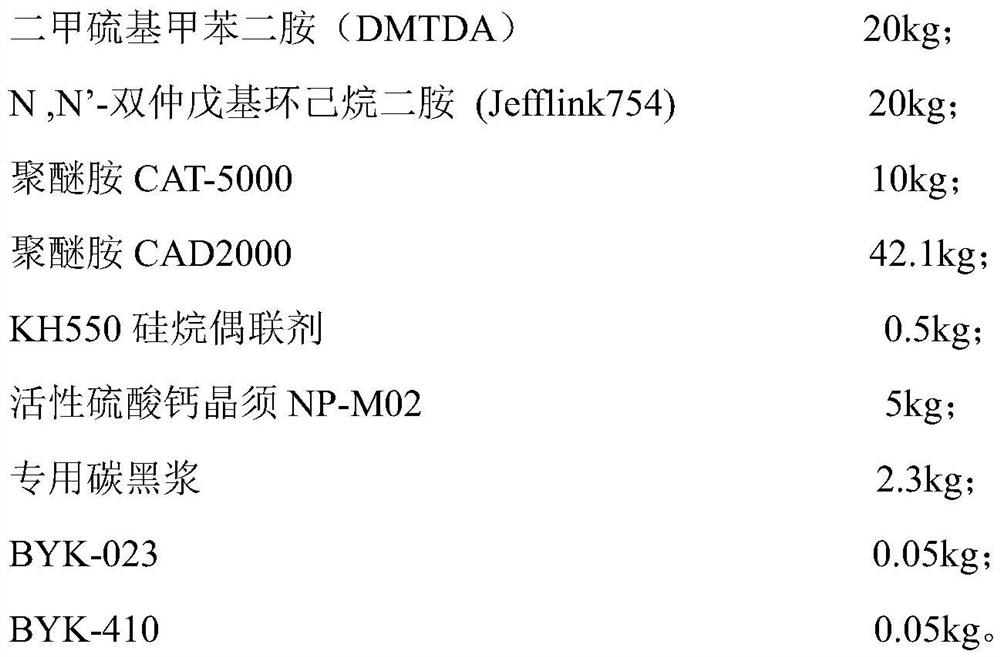

[0052]

[0053] 1.2) Preparation of component A

[0054] In the reaction flask containing 59kg of MDI-50, feed nitrogen gas, start stirring, raise the temperature to 50°C, and add 41kg of preheated PTMG-1000 in two batches, with an interval of 10 minutes between the two batches. Raise the temperature to 75°C to 95°C, continue to react for 3 hours, take a sample to measure the -NCO end group content in the semi-prepolymer is 16.1%, stop heating to obtain component A of the semi-prepolymer, place it in a closed container, degas and inflate Nitrogen for use.

[0055] 1.3) Preparation of component B

[0056] First add 15kg of polyetheramine CAD2000 and 0.5kg of KH550 silane coupling agent into the dispersion tank, stir at 300 rpm for 5 minutes, increase the speed t...

Embodiment 2

[0084] Repeat the A component, B component, C component, D component preparation steps and the preparation of composite coating of embodiment 1, only change A component, B component, C component, D component raw material allotment amount , other with embodiment 1. Raw material dosage range adjustment:

[0085] 1.1) Composition of A component and B component of flexible coating material

[0086] A component: MDI50 56.5kg, polytetrahydrofuran ether glycol (PTMG-1000) 43.5kg.

[0087] Component B: dimethylthiotoluenediamine (DMTDA) 20kg, N,N'-bis-sec-pentylcyclohexanediamine (Jefflink754) 18.5kg; polyetheramine CAT-5000 15kg, polyetheramine CAD2000 38.6kg ; KH550 silane coupling agent 0.5kg; active whisker silicon (GX-SiO 2 ) 5kg; special carbon black slurry 2.3kg; BYK-0230.05kg; BYK-410 0.05kg.

[0088] 1.2) Preparation of component A

[0089] Into the reaction flask containing 56.5kg of MDI-50, feed nitrogen gas, start stirring, raise the temperature to 50°C, and add 43.5kg ...

Embodiment 3

[0107] Repeat the A component, B component, C component, D component preparation steps and the preparation of composite coating of embodiment 1, only change A component, B component, C component, D component raw material allotment amount , other with embodiment 1. Raw material dosage range adjustment:

[0108] 1.1) Composition of A component and B component of flexible coating material

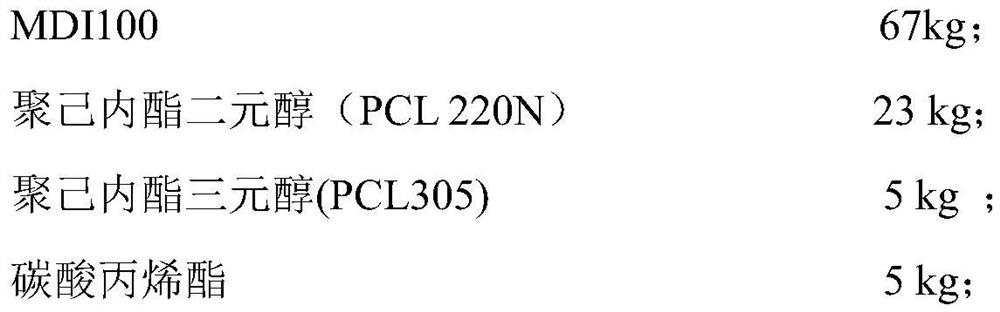

[0109] A component: MDI-100 66.2kg, polytetrahydrofuran ether glycol (PTMG-1000) 33.8kg.

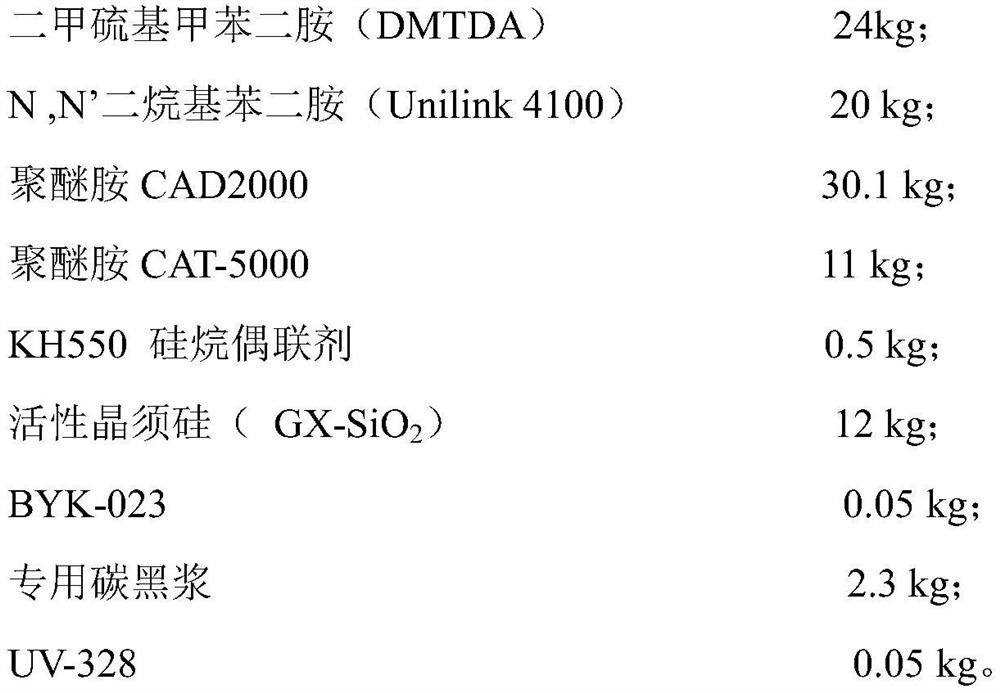

[0110] Component B: N,N'dialkylphenylenediamine (Unilink 4100) 35kg, N,N'-bis-sec-pentylcyclohexanediamine (Jefflink754) 15kg; polyetheramine CAT-5000 2kg, polyetheramine CAD2000 43.4kg; KH550 silane coupling agent 0.5kg; activated calcium sulfate whisker (NP-M02) 3kg; special carbon black paste 1kg; BYK-0230.05kg; BYK-410 0.05kg.

[0111] 1.2) Preparation of component A

[0112] Into the reaction flask containing 66.2kg of MDI-100, feed nitrogen gas, start stirring, raise the temperature to 50°C, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com