Preparation method for anti-aging silicone rubber used for compression seal products

A compression sealing and anti-aging technology, applied in the field of silicone rubber, can solve the problems of limited application of silicone rubber, low thermal strength of silicone rubber, low strength of raw silicone rubber, etc., to achieve excellent UV resistance and acid corrosion resistance, excellent mechanical performance, the effect of excellent electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

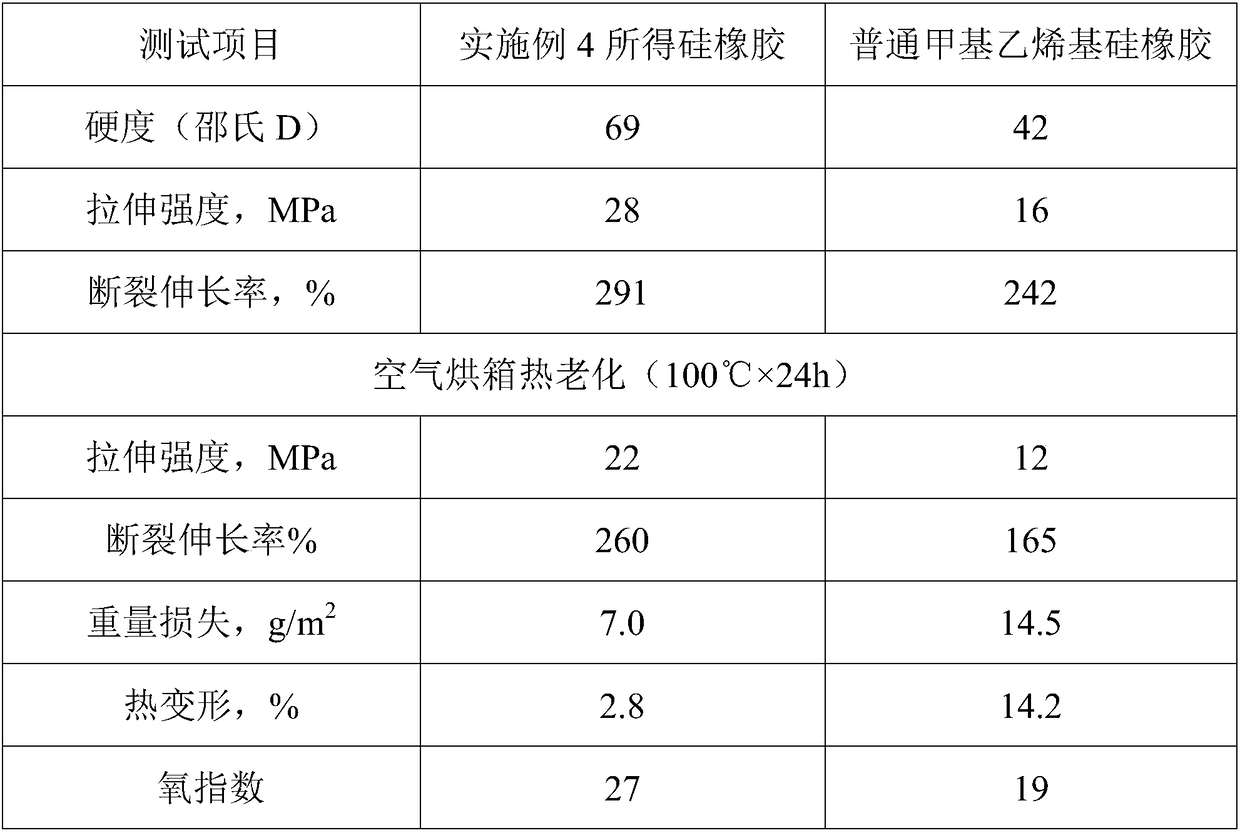

Examples

Embodiment 1

[0022] A preparation method of aging-resistant silicone rubber for compression sealing products, comprising the steps of:

[0023] S1. Stir 40kg of spherical alumina particles, 4kg of monomethoxypolyethylene glycol, and 80kg of methylene chloride, add 18kg of hydroxypropyl methacrylate, and 1kg of ethylene oxide and continue stirring for 20 minutes at a stirring speed of 1800r / min. Add 4 kg of hydrochloric acid with a concentration of 1.5 mol / L and 4 kg of polymerization inhibitor into a sealed reaction kettle, raise the temperature to 85°C under nitrogen protection, stir for 8 hours, let stand for 4 hours, cool, and wash to obtain the first material;

[0024] S2. Stir 90kg of methyl vinyl silicone rubber, 10kg of nitrile silicone rubber, 100kg of heavy calcium carbonate, 30kg of the first material, and 8kg of structure control agent for 10 minutes, adjust the temperature to 180°C, and stand in vacuum for 30 minutes, with a vacuum degree of 0.13kPa , to obtain the second mater...

Embodiment 2

[0027] A preparation method of aging-resistant silicone rubber for compression sealing products, comprising the steps of:

[0028] S1. Stir 80kg spherical alumina particles, 2kg monomethoxypolyethylene glycol, and 120kg dichloromethane, add 10kg hydroxypropyl methacrylate, and 2kg ethylene oxide and continue stirring for 10 minutes at a stirring speed of 2100r / min. Add 2 kg of hydrochloric acid with a concentration of 2.5 mol / L and 2 kg of polymerization inhibitor into a sealed reaction kettle, raise the temperature to 95°C under nitrogen protection, stir for 4 hours, let stand for 8 hours, cool, and wash to obtain the first material;

[0029] Among the spherical alumina particles, particles with a particle diameter of 20-40 μm account for 50 wt%, particles with a particle diameter of 60-100 μm account for 20 wt%, and the remaining particles have a particle diameter of 200-300 μm.

[0030] S2. Stir 70kg of methyl vinyl silicone rubber, 20kg of nitrile silicone rubber, 60kg of ...

Embodiment 3

[0033] A preparation method of aging-resistant silicone rubber for compression sealing products, comprising the steps of:

[0034] S1. Stir 50kg of spherical alumina particles, 3.5kg of monomethoxypolyethylene glycol, and 90kg of dichloromethane, add 16kg of hydroxypropyl methacrylate, and 1.2kg of ethylene oxide and continue stirring for 18 minutes at a stirring speed of 1900r / min, add 3.5 kg of hydrochloric acid with a concentration of 1.8 mol / L and 3.5 kg of polymerization inhibitor into a sealed reaction kettle, heat up to 88°C under nitrogen protection, stir for 7 hours, let stand for 5 hours, cool, and wash to obtain the first material;

[0035] Among the spherical alumina particles, particles with a particle size of 20-40 μm account for 30 wt%, particles with a particle size of 60-100 μm account for 30 wt%, and the remaining particles have a particle size of 200-300 μm.

[0036] S2. Stir 85kg of methyl vinyl silicone rubber, 12kg of nitrile silicone rubber, 90kg of hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com