Low dielectric PBT/PETG alloy nanometer injection molding composite material as well as preparation method and application thereof

A composite material and alloy nanotechnology, which is applied in the field of low-dielectric PBT/PETG alloy nano-injection composite material and its preparation, can solve the problems of high price, low output, and no solution to dielectric, and achieves low dielectric loss factor, Good mechanical properties, the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

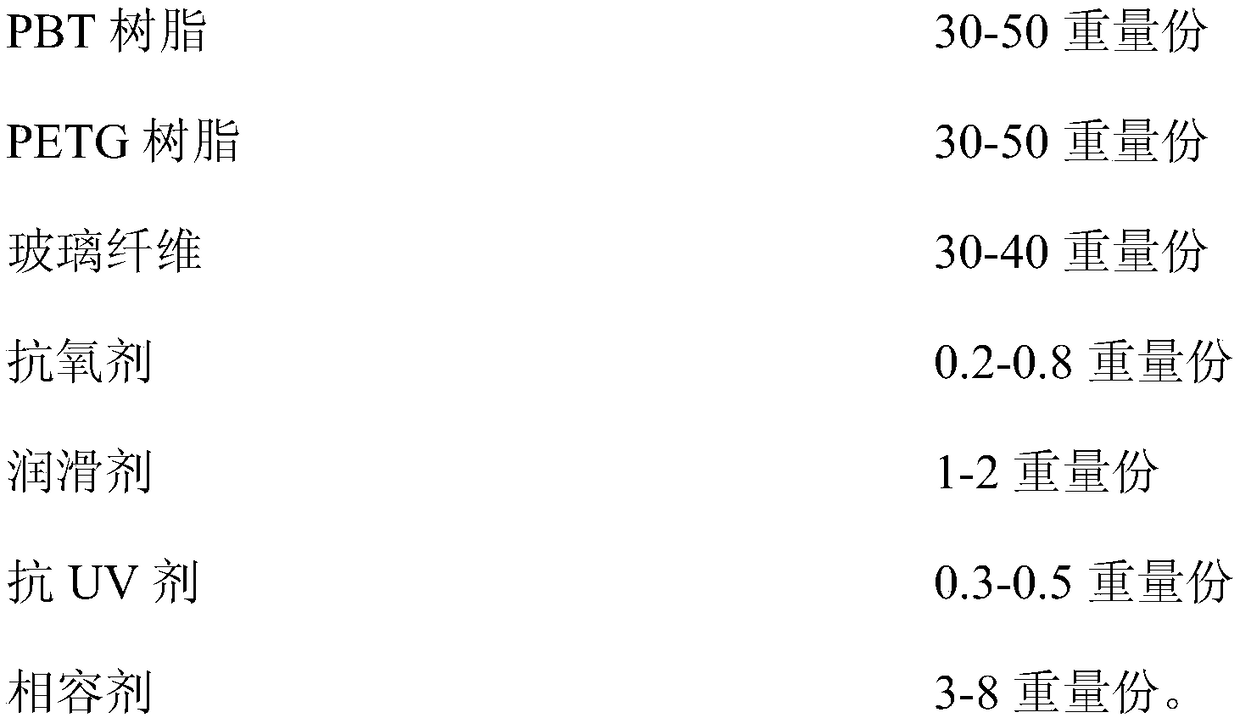

[0035] In this embodiment, the raw materials for the preparation of PBT / PETG alloy nano-injection molding composite materials include the following components by weight:

[0036]

[0037] Wherein, the antioxidant is antioxidant 1010, the lubricant is lubricant TAF, the anti-UV agent is ultraviolet absorber UV-531, and the compatibilizer is maleic anhydride grafted POE.

[0038] The preparation method is specifically:

[0039] (1) Mix PBT resin, PETG resin, antioxidant, lubricant, anti-UV agent and compatibilizer

[0040] (2) Utilize the twin-screw extruder to blend the mixture obtained in step (1), extrude, the extruding temperature is 220°C, the main engine speed of the twin-screw extruder is 350rpm / min, and the feeding speed The temperature is 20rpm / min to obtain a molten blend, and then glass fibers are added, sheared and meshed to obtain a PBT / PETG alloy nano-injection composite material.

Embodiment 2

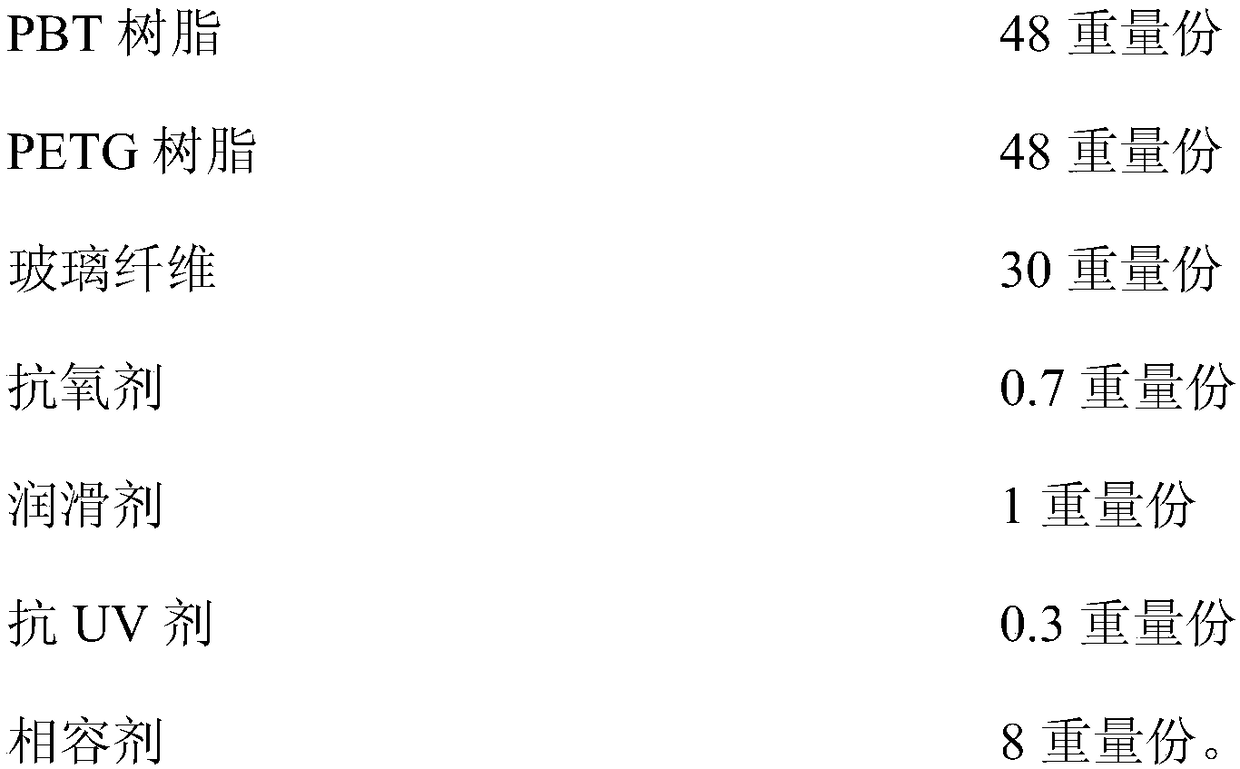

[0042] In this embodiment, the raw materials for the preparation of PBT / PETG alloy nano-injection molding composite materials include the following components by weight:

[0043]

[0044] Among them, the antioxidant is antioxidant 168, the lubricant is lubricant PETS, the anti-UV agent is ultraviolet absorber VSU, and the compatibilizer is maleic anhydride grafted polypropylene.

[0045] The preparation method is specifically:

[0046] (1) PBT resin, PETG resin and antioxidant, lubricant, anti-UV agent and compatibilizer are mixed evenly;

[0047](2) Utilize the twin-screw extruder to blend the mixture obtained in step (1), and extrude. The temperature is 30rpm / min to obtain a molten blend; then add glass fiber, shear and mesh to obtain a PBT / PETG alloy nano-injection composite material.

Embodiment 3

[0049] In this embodiment, the raw materials for the preparation of PBT / PETG alloy nano-injection molding composite materials include the following components by weight:

[0050]

[0051] Wherein, the antioxidant is antioxidant 1010, the lubricant is lubricant TAF, the anti-UV agent is ultraviolet absorber UV-531, and the compatibilizer is maleic anhydride grafted polypropylene.

[0052] The preparation method is specifically:

[0053] (1) PBT resin, PETG resin and antioxidant, lubricant, anti-UV agent and compatibilizer are mixed evenly;

[0054] (2) Utilize the twin-screw extruder to blend the mixture obtained in step (1), and extrude. The temperature is 10 rpm / min to obtain a molten blend, and then add glass fiber, shear and mesh to obtain a PBT / PETG alloy nano-injection composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com