Difunctionalized silica catalytic material as well as preparation and application thereof

A catalytic material, silicon oxide technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as expensive monomers and complicated and cumbersome preparation processes. Achieve the effect of simple preparation process, few synthesis steps and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Preparation of ionic liquid / benzyl alcohol bifunctional silicon oxide material SBA15-1

[0024] In a 250mL reaction flask, add 1g of silicon oxide material SBA15 and 0.248g (1mmol) 3-trimethoxysilane propyl acrylate, add 20mL of anhydrous toluene to the reaction flask, fully stir and reflux for 24 hours under a nitrogen atmosphere, and react After the system was cooled to room temperature, it was filtered, and the product was washed twice with 25 mL of ethanol, and dried in vacuum at 60° C. for 12 hours to obtain Allyl-SBA15, a silicon oxide material functionalized with double bonds. Take 1g of double-bond functionalized silicon oxide material Allyl-SBA15 into a 250mL reaction flask, add 50mL of N,N-dimethylformamide and stir to disperse, and dissolve 232mg (1mmol) of double bond-containing ionic liquid 1-vinyl- Add 3-butylimidazolium bromide and 536mg (4mmol) 4-vinylbenzyl alcohol into the reaction system, replace it with nitrogen and add 20mg of initiator a...

Embodiment 2

[0028] Example 2: Preparation of ionic liquid / benzyl alcohol bifunctional silicon oxide material SBA15-2

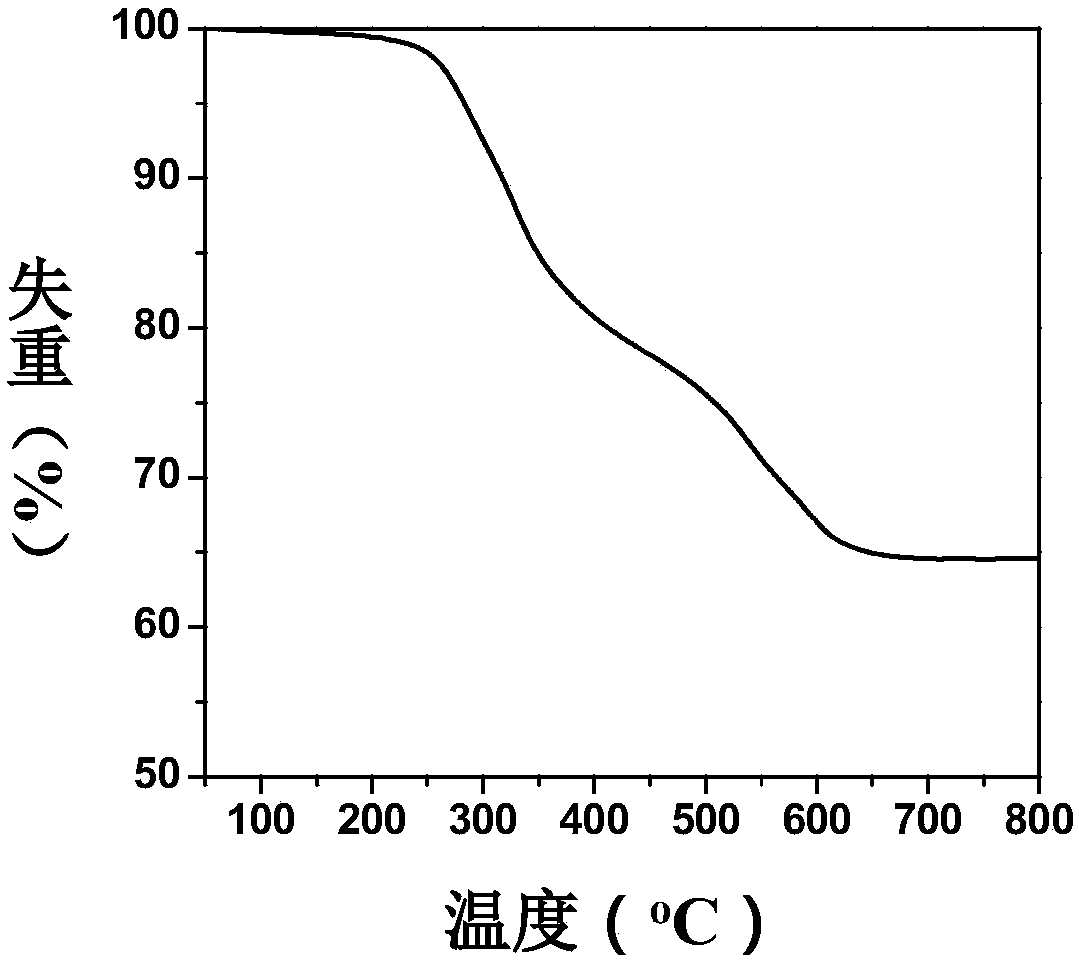

[0029]This example is basically the same as Example 1, except that the amount of the ionic liquid 1-vinyl-3-butylimidazolium bromide containing double bonds added is 470 mg (2 mmol), and the amount of 4-vinylbenzyl alcohol is added The amount was 269 mg (2 mmol). The measured specific surface area is 160m 2 / g, and the weight loss in the air atmosphere at 200-800°C was 41.0wt%.

Embodiment 3

[0030] Example 3: Preparation of ionic liquid / benzyl alcohol bifunctional silicon oxide material SBA15-3

[0031] This example is basically the same as Example 1, except that the amount of the ionic liquid 1-vinyl-3-butylimidazolium bromide containing double bonds added is 370 mg (1.6 mmol), and 4-vinylbenzyl alcohol is added The amount of is 430mg (3.2mmol). The measured specific surface area is 161m 2 / g, and the weight loss in the air atmosphere at 200-800°C is 35.5wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com