Poly(3-hydroxybutyrate-3-hydroxyhexanoate) carboxymethyl cellulose straw powder composite full biodegradable material

The technology of carboxymethyl cellulose and hydroxycaproate is applied in the field of polycarboxymethyl cellulose straw powder composite biodegradable material and its preparation, which can solve the problems of high cost, poor impact resistance, high brittleness and the like , to achieve the effect of product safety, good impact resistance, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

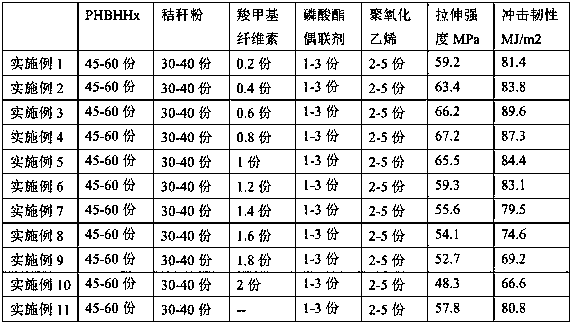

Examples

Embodiment 1

[0020] A poly(3-hydroxybutyrate-3-hydroxyhexanoate) carboxymethyl cellulose straw powder composite biodegradable material is prepared from the following raw materials in parts by weight: PHBHHx 45-60 parts, 30-40 parts of straw powder, 0.2 parts of carboxymethyl cellulose, 1-3 parts of phosphate coupling agent, 2-5 parts of polyethylene oxide.

[0021] In an embodiment of the present invention, the particle size of the straw fiber powder is 60 mesh.

[0022] In the embodiment of the present invention, the raw materials: PHBHHx (Dongguan Yingsheng Plastic Chemical Co., Ltd.); straw powder (Shaanxi Jinhe Agricultural Technology Co., Ltd.), carboxymethyl cellulose (Shijiazhuang Senlong Chemical Co., Ltd. ), phosphate coupling agent (Yangzhou Tianyang Auxiliary Co., Ltd.), polyethylene oxide (Zhengzhou Shengyu Chemical Products Co., Ltd.).

[0023] In the embodiment of the design of the present invention, the main instruments and equipment involved: constant temperature blast dry...

Embodiment 2

[0034] A poly(3-hydroxybutyrate-3-hydroxyhexanoate) carboxymethyl cellulose straw powder composite biodegradable material is prepared from the following raw materials in parts by weight: PHBHHx 45-60 parts, 30-40 parts of straw powder, 0.4 parts of carboxymethyl cellulose, 1-3 parts of phosphate coupling agent, 2-5 parts of polyethylene oxide.

[0035] In an embodiment of the present invention, the particle size of the straw fiber powder is 60 mesh.

[0036] In the embodiment of the present invention, the raw materials: PHBHHx (Dongguan Yingsheng Plastic Chemical Co., Ltd.); straw powder (Shaanxi Jinhe Agricultural Technology Co., Ltd.), carboxymethyl cellulose (Shijiazhuang Senlong Chemical Co., Ltd. ), phosphate coupling agent (Yangzhou Tianyang Auxiliary Co., Ltd.), polyethylene oxide (Zhengzhou Shengyu Chemical Products Co., Ltd.).

[0037]In the embodiment of the design of the present invention, the main instruments and equipment involved: constant temperature blast dryi...

Embodiment 3

[0048] A poly(3-hydroxybutyrate-3-hydroxyhexanoate) carboxymethyl cellulose straw powder composite biodegradable material is prepared from the following raw materials in parts by weight: PHBHHx 45-60 parts, 30-40 parts of straw powder, 0.6 parts of carboxymethyl cellulose, 1-3 parts of phosphate coupling agent, 2-5 parts of polyethylene oxide.

[0049] In an embodiment of the present invention, the particle size of the straw fiber powder is 60 mesh.

[0050] In the embodiment of the present invention, the raw materials: PHBHHx (Dongguan Yingsheng Plastic Chemical Co., Ltd.); straw powder (Shaanxi Jinhe Agricultural Technology Co., Ltd.), carboxymethyl cellulose (Shijiazhuang Senlong Chemical Co., Ltd. ), phosphate coupling agent (Yangzhou Tianyang Auxiliary Co., Ltd.), polyethylene oxide (Zhengzhou Shengyu Chemical Products Co., Ltd.).

[0051] In the embodiment of the design of the present invention, the main instruments and equipment involved: constant temperature blast dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com