Preparation method of high-fluorescent fluorescence carbon quantum dots and application of high-fluorescent fluorescence carbon quantum dots in Cr (VI) detection

A technology of carbon quantum dots and fluorescent performance, which is applied in the preparation and application of fluorescent sensors with high fluorescent performance, can solve the problems of limited use and inconvenience, and achieve low cost, simple and convenient operation, high detection sensitivity and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

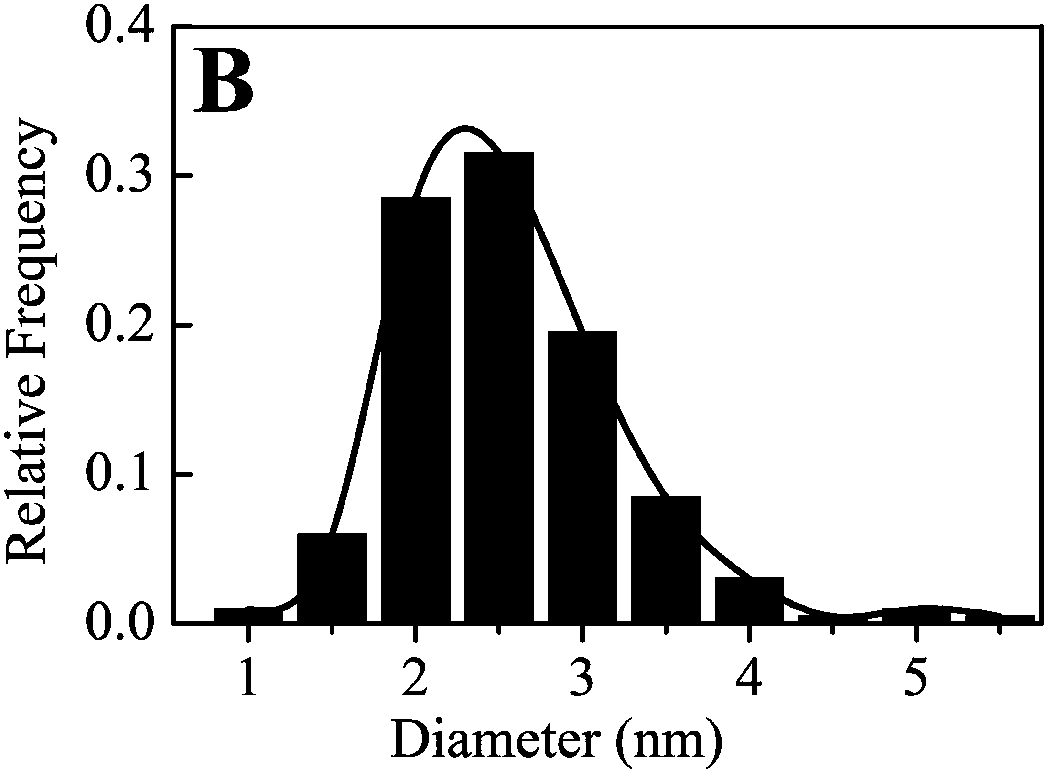

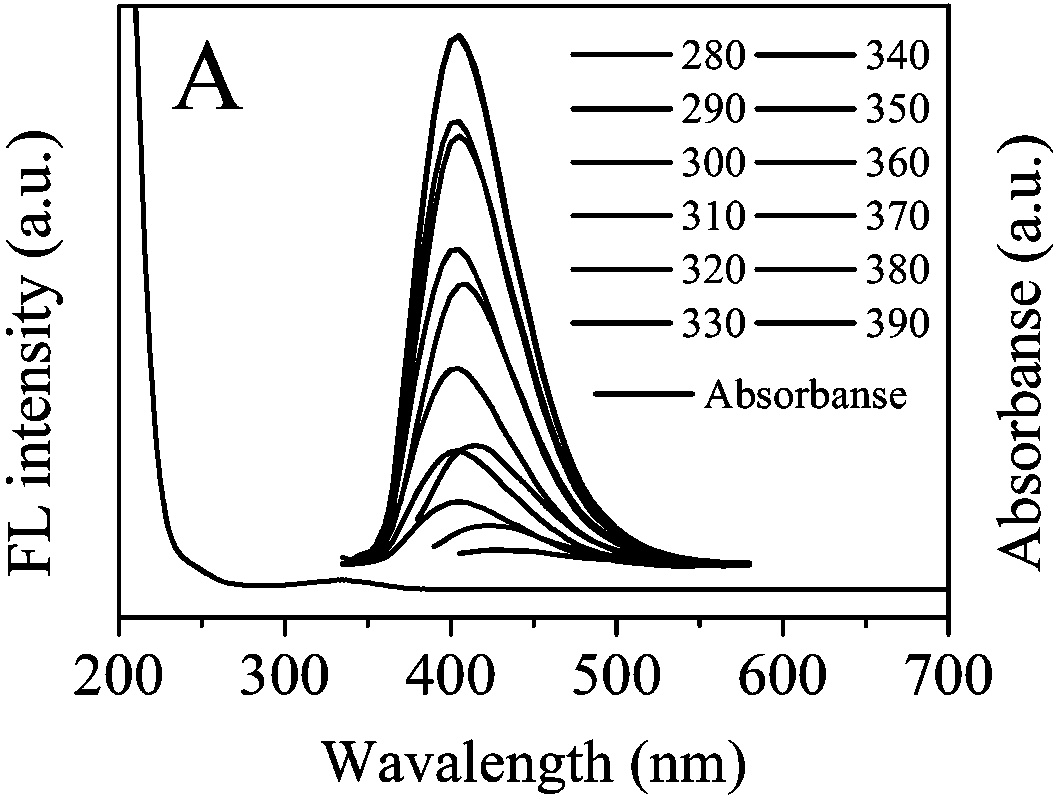

[0031]Example 1. Preparation of carbon nanofluorescent probes: Dissolve citric acid (0.35 g) and glycine (0.35 g) in 7 mL of water, and then transfer the solution to a poly(tetrafluoroethylene)-lined autoclave at 190 After heating in an oven at ℃ for 48 hours and naturally cooling to room temperature, a dark brown suspension containing fluorescent carbon quantum dots was obtained. After centrifuging at 4000 rpm for 10 minutes to remove large particles, a D101 macroporous adsorption resin column was used, and water was used as a wash. The crude product was deliquified and purified, and the fluorescent carbon quantum dots were concentrated by a vacuum rotary evaporator, and then freeze-dried to obtain purified fluorescent carbon quantum dots as a white powder. figure 1 ) can detect fluorescent carbon nanoparticles with good particle dispersion and an average particle size of 2.5 nm, which can be detected by fluorescence spectroscopy, ultraviolet spectroscopy (such as figure 2 )...

Embodiment 2

[0032] Example 2, establishment of a standard curve between Cr(IV) concentration and fluorescence intensity: take the fluorescent carbon quantum dots in Example 1 and prepare a carbon nanoparticle solution with a concentration of 0.05 g / ml, and prepare 1 ml of each The carbon nanoparticle solution was used as the blank control group; another 15 centrifuge tubes were added with 1 ml of the prepared carbon nanoparticle solution, and then 5 ml of Cr(IV) were added to the 15 centrifuge tubes with concentrations of 5, 10, 20, respectively. 30, 40, 50, 60, 70, 80, 90, 100, 110, 120, 150, 200, 500, 1000 μM aqueous solution, after mixing thoroughly, the obtained carbon nanoparticles and the standard solution of Cr(IV) were allowed to stand for 1 min Finally, the fluorescence intensity F1 in the standard solution was detected by a fluorescence photometer whose detection wavelength range covers 280-700 nm. The detection conditions were that the excitation wavelength was 340 nm, the emiss...

Embodiment 3

[0033] Example 3, detection of actual samples: Take the fluorescent carbon quantum dots in Example 1, take tap water as a sample, and filter through a 0.22 μm membrane before analysis, the concentration of carbon dots is 0.05 mg / mL, take 1 ml of pure water Add 1 ml of the prepared carbon nanoparticle solution as a blank control group, and the measured fluorescence intensity is F 0 , Take 1 ml of tap water and mix it with 1 ml of carbon nanoparticles with a concentration of 0.05 mg / ml to detect the fluorescence intensity F1, according to the linear regression equation (F 0 -F 1 ) / F 0 = 0.00274x+ 0.01637, calculated as not detected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com