Preparation technology for light and high-strength jute fiber composite board and production system

A preparation process and technology of hemp fiber, which is applied in the directions of fiber treatment, plant fiber, heating/cooling fabric, etc., can solve the problems of poor fiber distribution uniformity, poor interface compatibility, and low bonding force between hemp fiber and polypropylene fiber, etc. Good fiber uniformity, increase bonding strength, and improve the effect of overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

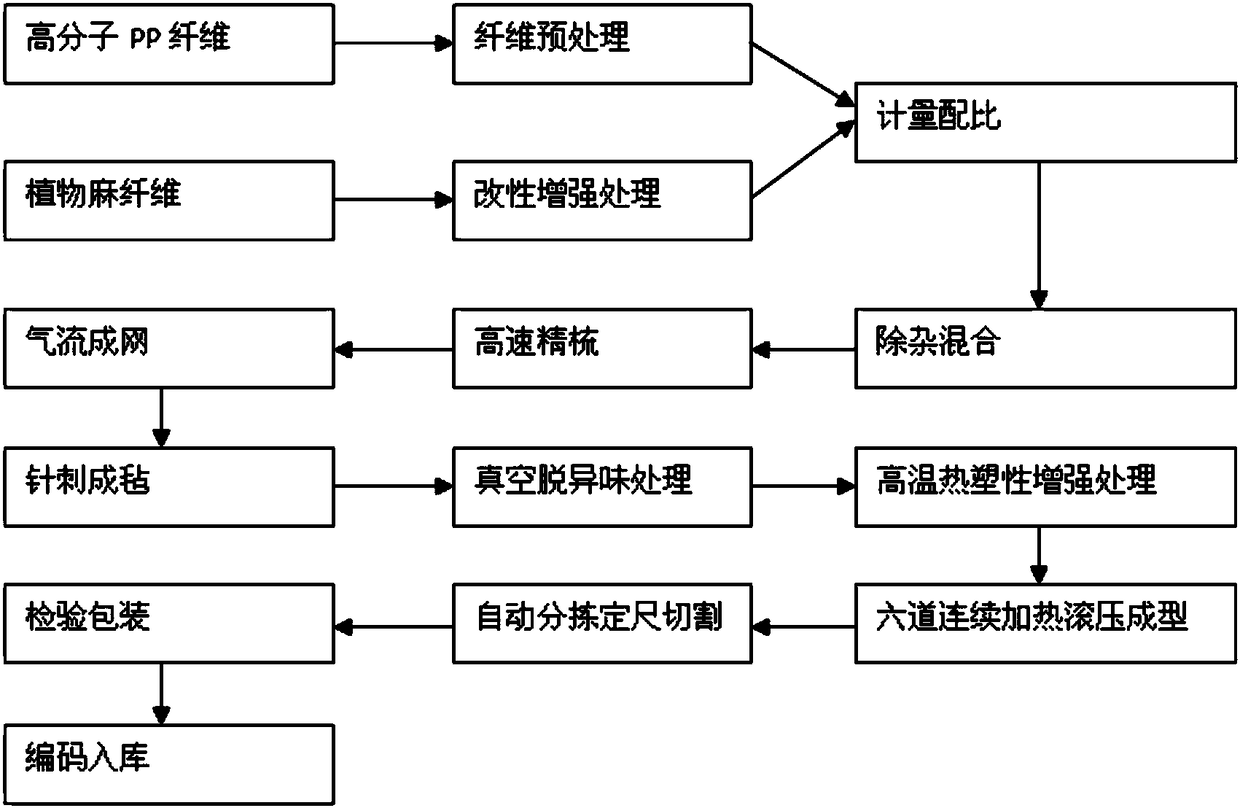

[0046] Such as figure 1 Shown to be the embodiment of the preparation technology of a kind of lightweight high-strength hemp fiber composite board of the present invention, comprise following procedure:

[0047] Process 1. Raw material preparation and pretreatment process: use polymer PP fiber and plant hemp fiber as raw materials for the preparation of hemp fiber composite board, and modify and strengthen the plant hemp fiber; loosen the polymer PP fiber;

[0048] Process 2, metering and proportioning process: the polymer PP fiber and plant hemp fiber are weighed and proportioned;

[0049] Process 3, impurity removal and mixing process: mixing the polymer PP fiber and plant hemp fiber in process 2 and removing impurities;

[0050] Process 4. Combing process: use a high-speed combing machine to comb the fibers after cleaning and mixing;

[0051] Process 5. Air-laid process: use an air-laid machine to make a fiber web from the combed mixed fibers;

[0052] Process 6. Needling ...

Embodiment 2

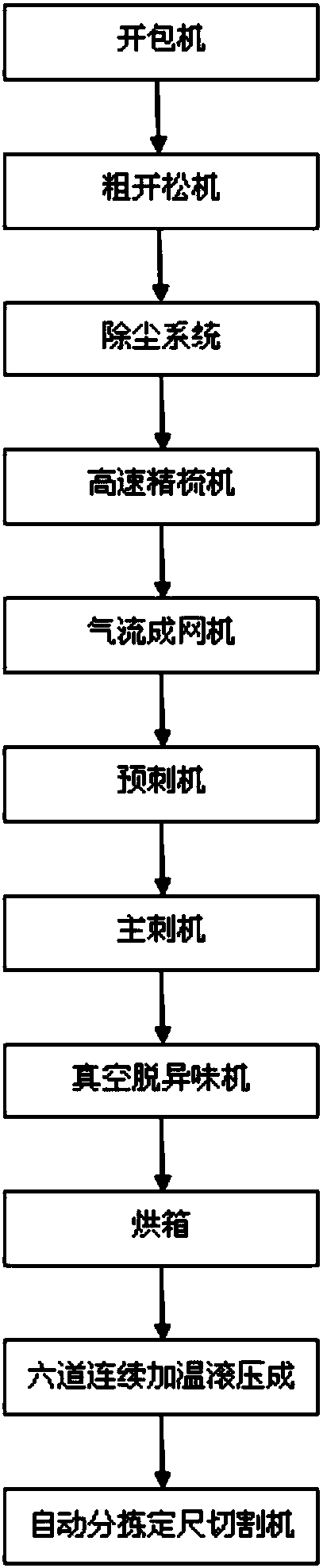

[0074] Such as figure 2 Shown is an embodiment of the production system of the preparation process of a light-weight high-strength hemp fiber composite board of the present invention, including the equipment arranged in sequence according to the order of logistics from input to output: bale opener→rough opener→ Dust removal system→high-speed combing machine→air-laid machine→pre-looming machine→main looming machine→vacuum deodorization machine→oven→six continuous heating roll forming machine→automatic sorting and cutting machine.

Embodiment 3

[0076] Take the hemp fiber composite board adopting conventional technology and the hemp fiber composite board adopting the present invention, and carry out density detection and strength test respectively. Among them, the hemp fiber in the preparation process of the hemp fiber composite board using the conventional process does not undergo modification and strengthening treatment, and the web forming process adopts a web laying machine to form a web.

[0077] The density data of the measured hemp fiber composite board is as follows:

[0078]

Hemp fiber composite board using conventional technology

Adopt hemp fiber composite board of the present invention

density

0.54g / cm 3

0.38g / cm 3

[0079] The measured tensile strength and bending strength data are compared as follows:

[0080]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com