A kind of preparation method of gas phase fluorination catalyst

A fluorination catalyst and gas-phase fluorination technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low activity of fluorination catalysts, reduced specific surface area, frequent regeneration and activation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

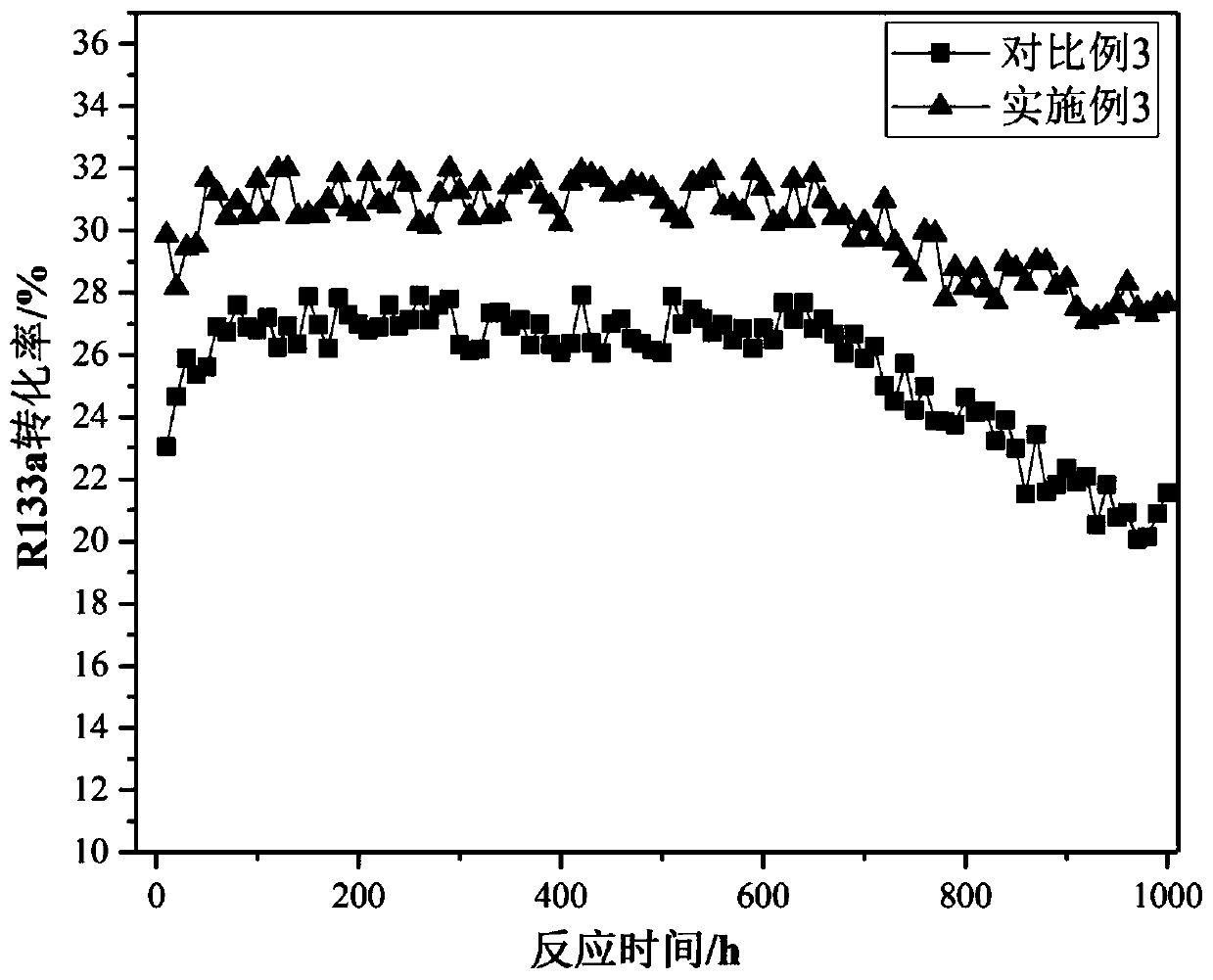

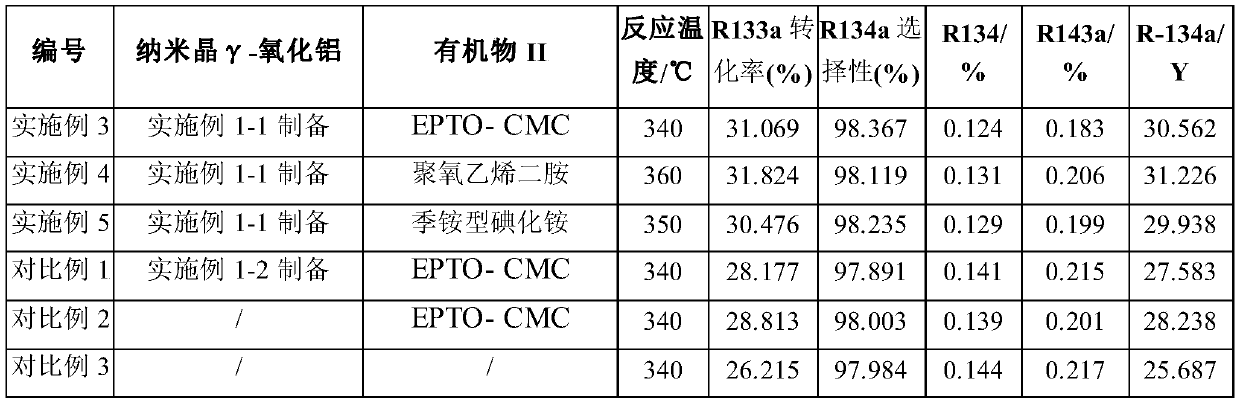

Examples

Embodiment 1-1

[0071] The preparation of embodiment 1-1 nanocrystalline γ-alumina powder

[0072] 25.03g Al(NO 3 ) 3 9H 2 O, 1.35g MgCl 2 , 0.21gLaCl 3 1. 1g of organic matter I (0.26g of isopropanol + 0.56g of tartaric acid + 0.18g of glucose) was dissolved in 500mL of ethanol solvent, refluxed at 80°C for 2h, then added dropwise with ammonium carbonate aqueous solution for 10min, and then maintained the reaction Crystallize at high temperature for 12 hours to obtain a liquid sol, then vacuum dry the liquid sol at 110°C for 12 hours to obtain a solid gel, and finally roast at 550°C for 3 hours to obtain nanocrystalline γ-alumina powder, which is used as a carrier for future use.

Embodiment 1-2

[0073] The preparation of embodiment 1-2 nanocrystalline gamma-alumina powder

[0074] 25.03g Al(NO 3 ) 3 9H 2 O was dissolved in 500mL ethanol solvent, refluxed at 80°C for 2h, then ammonium carbonate aqueous solution was added dropwise for 10min, and then crystallized at the reaction temperature for 12h to obtain a liquid sol, and then the liquid sol was vacuum-dried at 110°C After 12 hours, a solid gel was obtained, and finally the nanocrystalline γ-alumina powder was obtained by roasting at 550°C for 3 hours.

Embodiment 2

[0075] The preparation of embodiment 2 amorphous chromium oxide powder

[0076] Weigh 50.02g CrCl 3 ·6H 2 O, 1.85gMgCl 2 , 2.81g AlCl 3 , 1.53gZnCl 3 , 0.21g LaCl 3 , 2.49g organic matter I (0.68g ethanol+1.42g citric acid+0.39g sucrose) was dissolved in 900mL deionized water to obtain a mixed salt solution, the mixed salt solution was mixed with ammonia water until the solution pH=10, filtered and washed with water to obtain a sample, The sample was dried in an oven at 110°C for 6 hours, and then transferred to a roasting furnace. 2 Roast at a high temperature of 350°C for 3 hours in the atmosphere, crush and sieve the calcined sample to obtain amorphous chromium oxide powder for future use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com