Reflecting film

A technology of reflective film and optical surface, applied in the optical field, can solve the problems of reduced reflective brightness and scratches of reflective film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] The present invention also provides a method for preparing a reflective film, the method comprising the following steps:

[0069] (1) Coating solution for anti-fouling and anti-scratch coating: add each component of the coating solution into the barrel according to the ratio, stir and disperse until the mixture is uniform, and then filter to obtain a UV-curable coating;

[0070] (2) coating the first optical surface of the substrate layer with the coating solution of step (1), and curing the coating solution under ultraviolet light irradiation to obtain an anti-fouling and anti-scratch coating;

[0071] (2) preparing a microprism structure layer on the second optical surface of the substrate layer;

[0072] (3) bonding the bonding layer on the second optical surface of the sealing layer, pressing the microprism structure layer in the step (2) tightly on the first optical surface of the sealing layer;

[0073] (4) The adhesive layer on the second optical surface of the ...

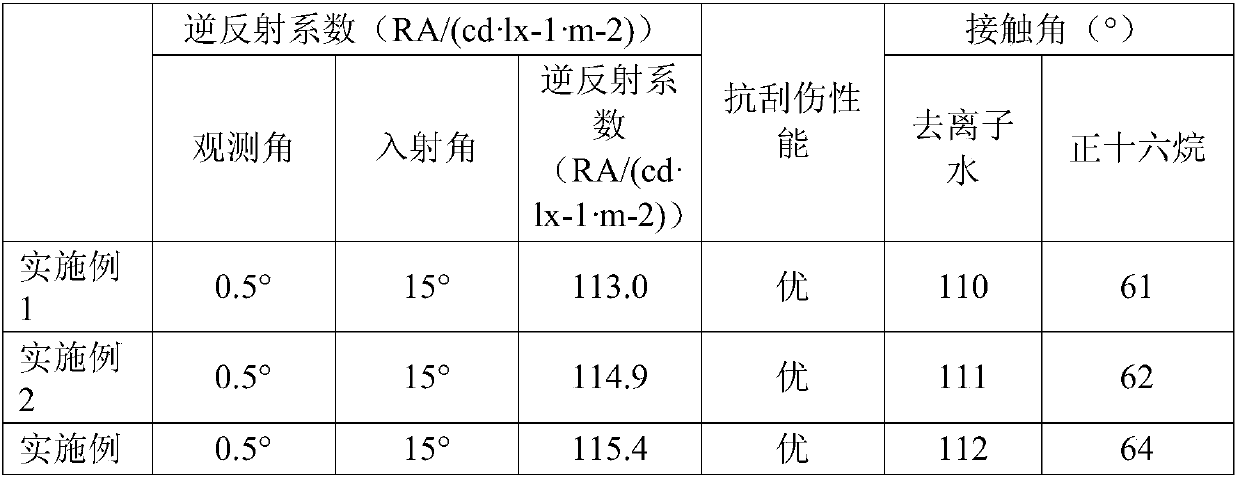

Embodiment 1

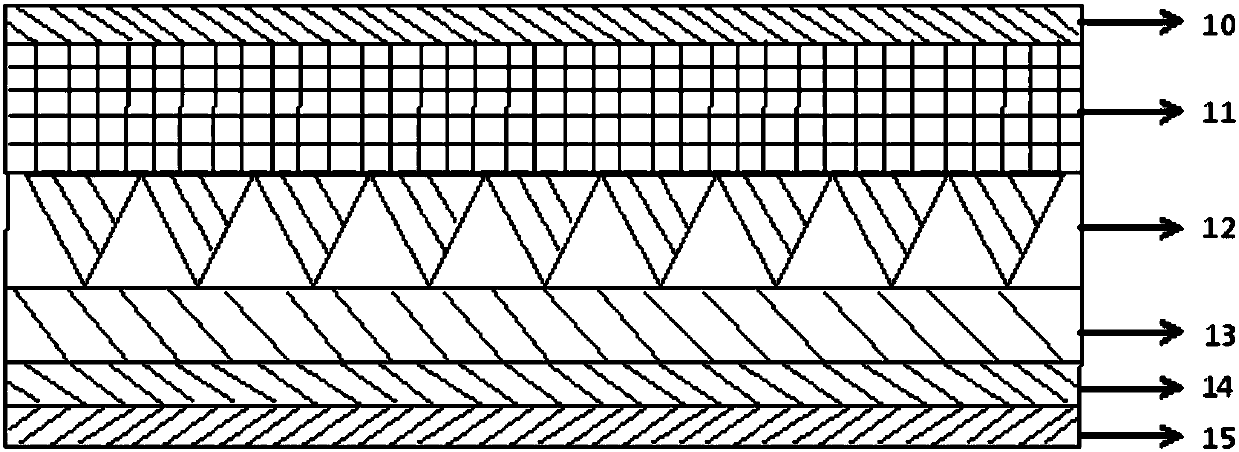

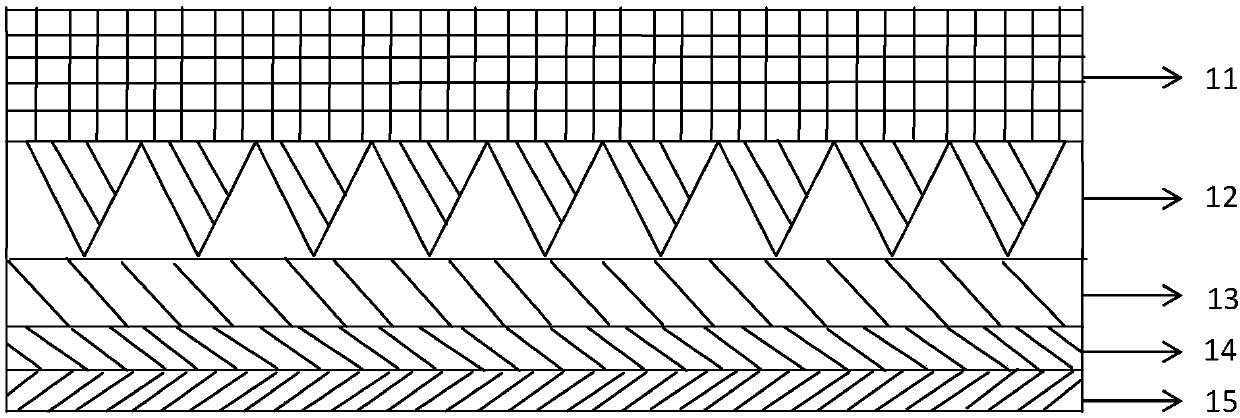

[0079] The present invention provides a reflective film, which comprises an antifouling and scratch-resistant coating 10 , a substrate layer 11 , a microprism structure layer 12 , a sealing layer 13 , an adhesive layer 14 and a peeling layer 15 in sequence.

[0080] The coating solution of the antifouling and anti-scratch coating comprises 25% acrylate oligomer, 30% reactive diluent, 0.3% antifouling additive, 0.5% leveling agent, 1% photoinitiator Agent, 43.2% solvent, said percentage is weight percentage.

[0081] Described acrylate oligomer is polyether acrylate oligomer and urethane acrylate oligomer, and the weight ratio of the two is 1:4; Reactive diluent is butyl acrylate, pentaerythritol tetraacrylate, the weight of both The ratio is 3:2; the antifouling additives are perfluorobutyl acrylate and pentafluorooctyl acrylate, and the weight ratio of the two is 1:1; the leveling agent is polyether modified siloxane; the photoinitiator is (1-hydroxycyclohexyl phenyl ketone ...

Embodiment 2

[0084] For the reflective film provided in Example 1, the coating solution of the antifouling and scratch-resistant coating includes 35% acrylate oligomer, 35% reactive diluent, 0.5% antifouling additive, 0.3% Leveling agent, 2% photoinitiator, 27.2% solvent, said percentage is weight percentage.

[0085] Described acrylate oligomer is polyester acrylate oligomer and polyurethane acrylate oligomer, and the weight ratio of the two is 3:7; Reactive diluent is tripropylene glycol diacrylate (TPGDA), trimethylol Propane tri(meth)acrylate (TMPTA), the weight ratio of the two is 1:1; the antifouling additive is perfluorobutyl methacrylate and pentafluorooctyl methacrylate, and the weight ratio of the two is 1:1; leveling agent is polyether modified siloxane; photoinitiator is (2-hydroxy-methylphenyl propane-1-one (1173), 2,4,6 (trimethylbenzoyl Diphenylphosphine oxide) (TPO), the weight ratio of the two is 3:2; the solvent is ethyl acetate, butyl acetate, and the weight ratio of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com