A method to simultaneously improve the interfacial strength and toughness of carbon fiber epoxy composites

A composite material, interfacial strength technology, applied in the direction of carbon fiber, fiber processing, textiles and papermaking, etc., can solve the problem of not being able to improve the strength and toughness of the fiber and resin interface at the same time, achieve easy industrial production, improve wettability, repeatable good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

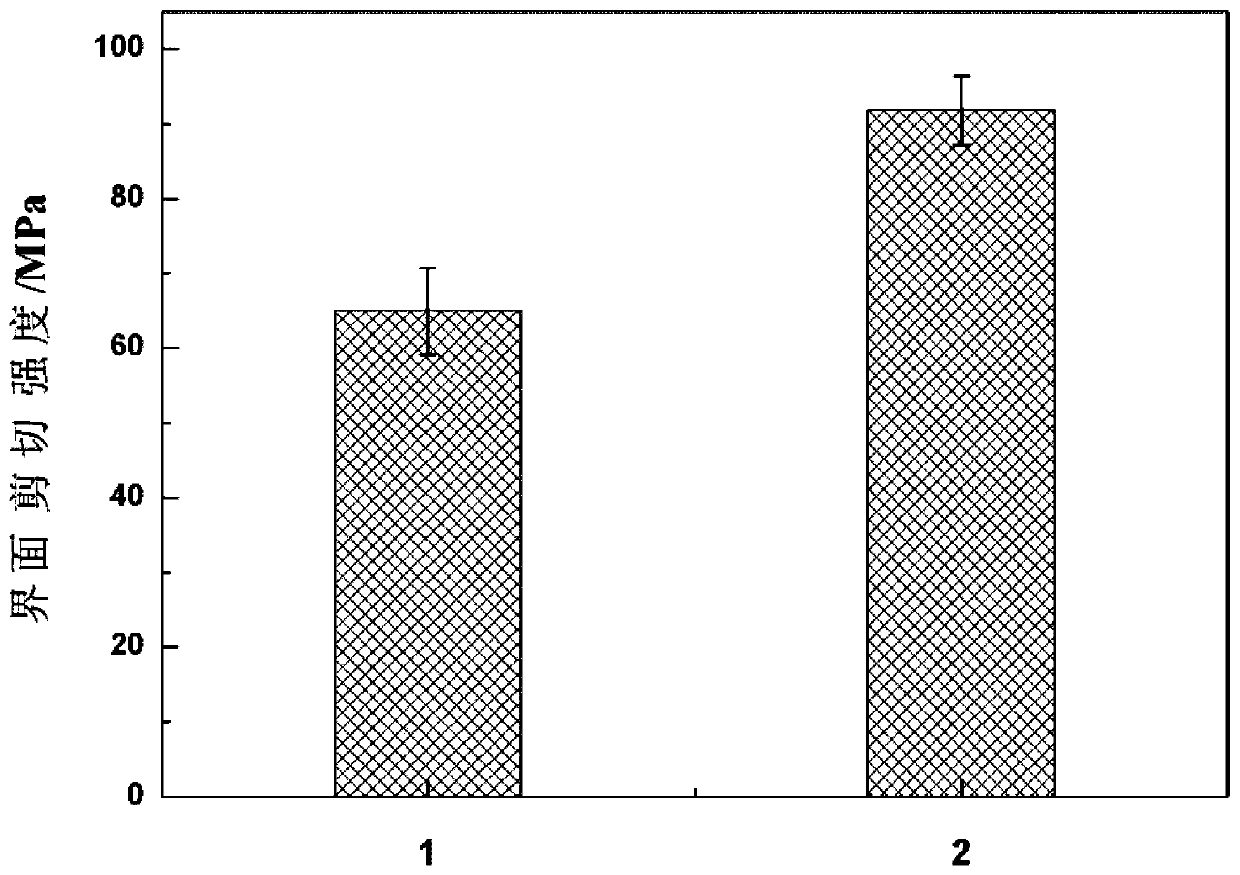

Embodiment 1

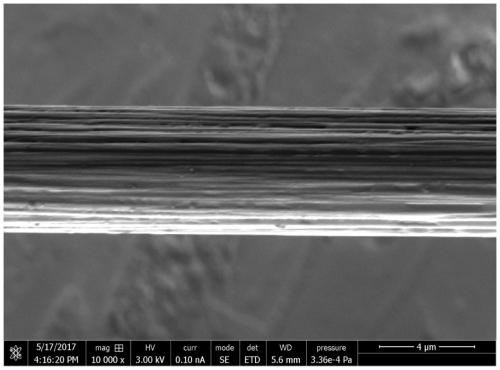

[0030] 1) Silane coupling agent modified ZrO 2

[0031] ZrO with a particle size of 10-100nm 2 Nanoparticles and ethanol solution were mixed at a mass ratio of 1:20 and magnetically stirred for 2 hours to ensure that ZrO 2 The particles are uniformly dispersed in ethanol solution to obtain ZrO 2 Ethanol solution; according to the mass ratio of 3-aminopropyltriethoxysilane coupling agent: ethanol solution: deionized water = 1:5:0.2, mix the silane coupling agent with the ethanol solution and add deionized water to it magnetically Stir for 10 minutes to promote the hydrolysis of the silane coupling agent to obtain a silane coupling agent mixture; press ZrO 2 The mass ratio of nanoparticles and silane coupling agent is 1:1, and the silane coupling agent mixture is added to the ZrO 2 In the ethanol solution, stir at 60°C for 3h to complete the conversion of the silane coupling agent to ZrO 2 Grafting, the grafted ZrO 2 The particles were washed with water and ethanol respect...

Embodiment 2

[0042] 1) Silane coupling agent modified ZrO 2

[0043] ZrO with a particle size of 10-100nm 2 Nanoparticles and ethanol solution were mixed at a mass ratio of 1:1 and magnetically stirred for 6 hours to ensure that ZrO 2 The particles are uniformly dispersed in ethanol solution to obtain ZrO 2Ethanol solution; according to the mixture of γ-glycidyl etheroxypropyltrimethoxysilane and 3-[2-(2-aminoethylamino)ethylamino]propyl-trimethoxysilane: ethanol solution: deionized water =1:10:0.3 mass ratio Mix the silane coupling agent with the ethanol solution, then add dropwise deionized water to it and stir magnetically for 5 minutes to promote the hydrolysis of the silane coupling agent to obtain the silane coupling agent mixed solution; according to ZrO 2 The mass ratio of nanoparticles to silane coupling agent is 1:2, and the silane coupling agent mixture is added to the ZrO 2 In the ethanol solution, stir at 60°C for 1h to complete the conversion of the silane coupling agent ...

Embodiment 3

[0052] 1) Silane coupling agent modified ZrO 2

[0053] ZrO with a particle size of 10-100nm 2 Nanoparticles and ethanol solution were mixed at a mass ratio of 1:50 and magnetically stirred for 0.5h to ensure that ZrO 2 The particles are uniformly dispersed in ethanol solution to obtain ZrO 2 Ethanol solution; according to the mass ratio of 3-aminopropyltrimethoxysilane coupling agent: ethanol solution: deionized water = 1:8:0.1, mix the silane coupling agent with the ethanol solution and add deionized water dropwise to it with magnetic stirring 8min to promote the hydrolysis of the silane coupling agent to obtain the silane coupling agent mixture; press ZrO 2 The mass ratio of nanoparticles to silane coupling agent is 1:3, and the silane coupling agent mixture is added to the ZrO 2 In the ethanol solution, stir at 60°C for 2h to complete the conversion of the silane coupling agent to ZrO 2 Grafting, the grafted ZrO 2 The particles were washed with water and ethanol resp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com