High thermal conductivity composite sand core for aluminum alloy casting, and preparation method of high thermal conductivity composite sand core

A composite sand core and aluminum alloy technology, which is applied in the field of aluminum alloy casting, can solve problems such as coarse grains, difficulty in setting cold iron, and unstable mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

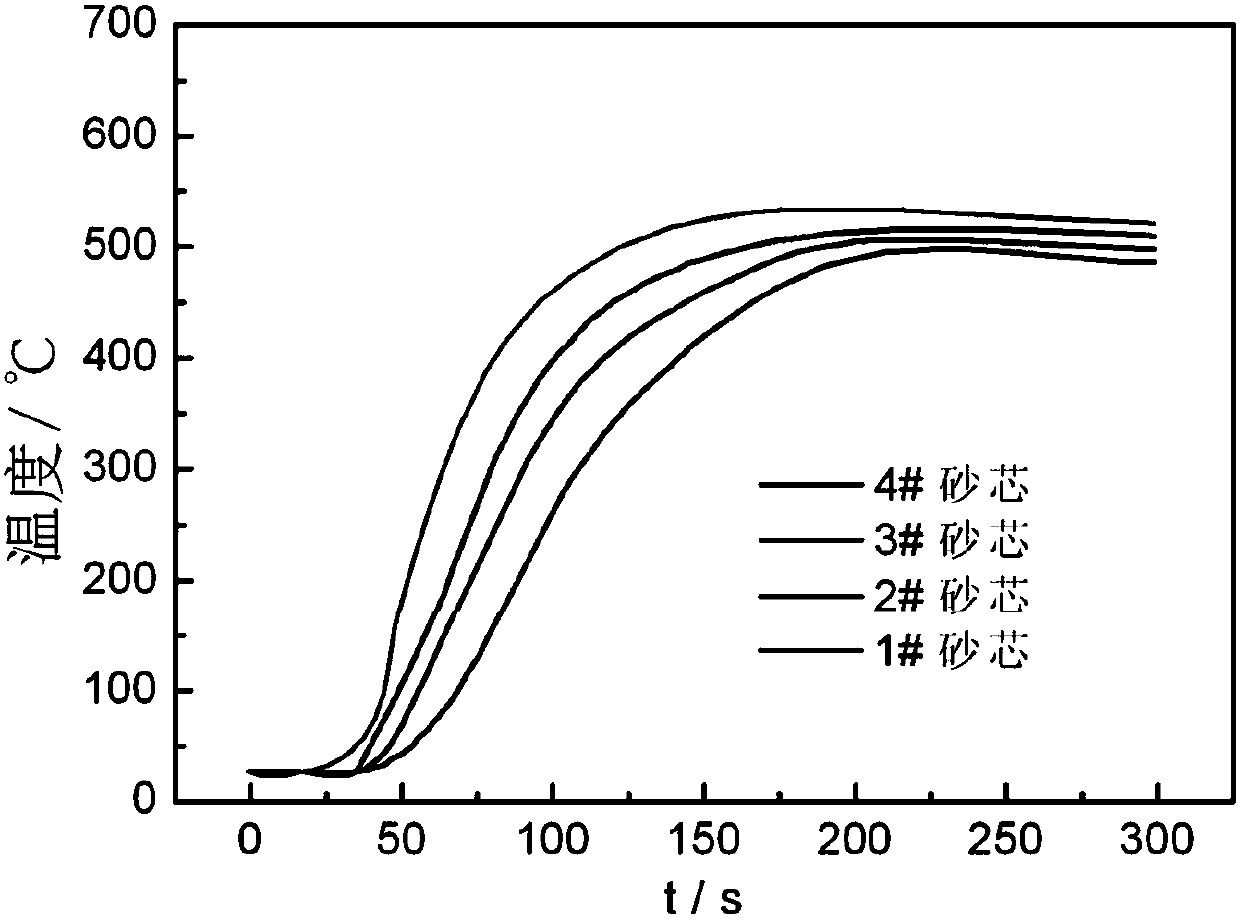

Embodiment 1

[0016] This embodiment is an aluminum-silicon ZL114A special-shaped shell casting. The thickness of the scattered and isolated thermal joints is 12mm, and the size is 50mm×50mm. The process is sand gravity casting, and the composition and mass percentage of the composite sand core are iron powder (40 mesh to 70 mesh) 20%, limestone sand (40 mesh to 70 mesh) 10%, zircon sand (70 mesh to 140 mesh) 6 %, and the rest is scrubbing sand (40 mesh to 70 mesh). The sand core binder is phenolurethane resin, the amount of resin component I added is 0.6% of the sand weight, the amount of resin component II added is 0.8% of the sand weight, and the amount of curing agent added is 1.0% of the total weight of the resin. Resin component I is phenyl ether phenolic resin, resin component II is polyisocyanic acid, and curing agent is liquid tertiary amine.

[0017] The preparation method of the sand core is as follows: first add the phenol urethane resin curing agent to component I, mix well, a...

Embodiment 2

[0020] This embodiment is an aluminum-copper ZL205A cabin body casting. The size of the hot joint of the internal rib plate is 18mm, the surrounding wall thickness is 5mm, and the hot joint is in transition with other parts of the curved surface. The process is sand gravity casting, and the composition and mass percentage of the composite sand core are iron powder (70 mesh to 140 mesh) 35%, limestone sand (70 mesh to 140 mesh) 15%, zircon sand (40 mesh to 70 mesh) 8 %, and the rest is scrubbing sand (40 mesh to 70 mesh). The sand core binder is phenol urethane resin, the addition of resin component I is 0.8% of the sand weight, the addition of resin component II is 0.6% of the sand weight, and the addition of curing agent is 1.2% of the total weight of the resin. Resin component I is phenyl ether phenolic resin, resin component II is polyisocyanic acid, and curing agent is liquid tertiary amine.

[0021] The preparation method of the sand core is as follows: first add the phe...

Embodiment 3

[0024] This embodiment is an aluminum-magnesium ZL305 special-shaped box casting. The maximum thickness of the isolated curved surface heat joint is 22mm, and the rest is a uniform transition to a thickness of 8mm. The heat joint size is 35mm×60mm. The process is sand mold low-pressure casting. The composition and mass percentage of the composite sand core are iron powder (40 mesh to 70 mesh) 45%, limestone sand (70 mesh to 140 mesh) 18%, zircon sand (70 mesh to 140 mesh) 8% %, potassium fluoroborate (200 mesh) 0.6%, sulfur powder (200 mesh) 0.5%, and the rest is scrubbing sand (40 mesh to 70 mesh). The sand core binder is phenol urethane resin, the amount of resin component I added is 0.9% of the sand weight, the amount of resin component II added is 1.0% of the sand weight, and the amount of curing agent added is 1.2% of the total weight of the resin. Resin component I is phenyl ether phenolic resin, resin component II is polyisocyanic acid, and curing agent is liquid tertia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com