Casting system and preparation method of aluminum matrix composite material casting

An aluminum-based composite material and temperature control system technology, which is applied in the field of composite material preparation, can solve the problems of incomplete forming and poor fluidity, and achieve the effects of good forming, good wear resistance, and improved feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

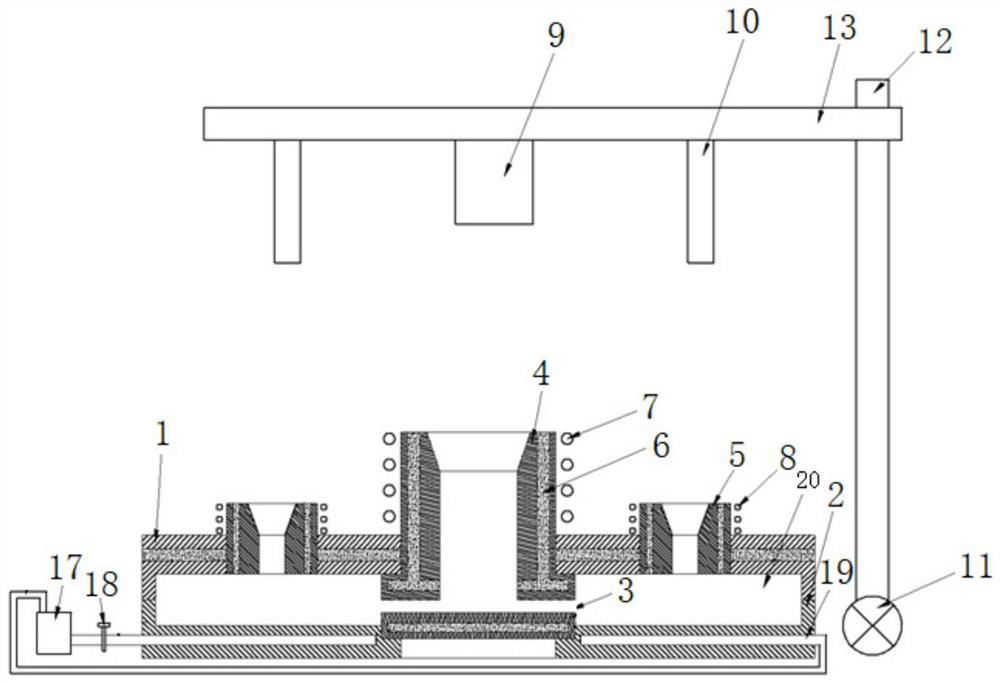

[0065] Prepare 20% SiC / AHS-2 composite material casting, the middle layer is 3cm insulation cotton.

[0066] First, turn on the heaters at the gate and riser, and raise the temperature of the mold to 400°C to heat the melt and avoid the melt from clogging at the gate during filling;

[0067] After heating up, turn on the cooling water system of the lower mold, and pour the smelted 700°C composite material melt into the cavity, and stop casting when the melt starts to flow out from the riser;

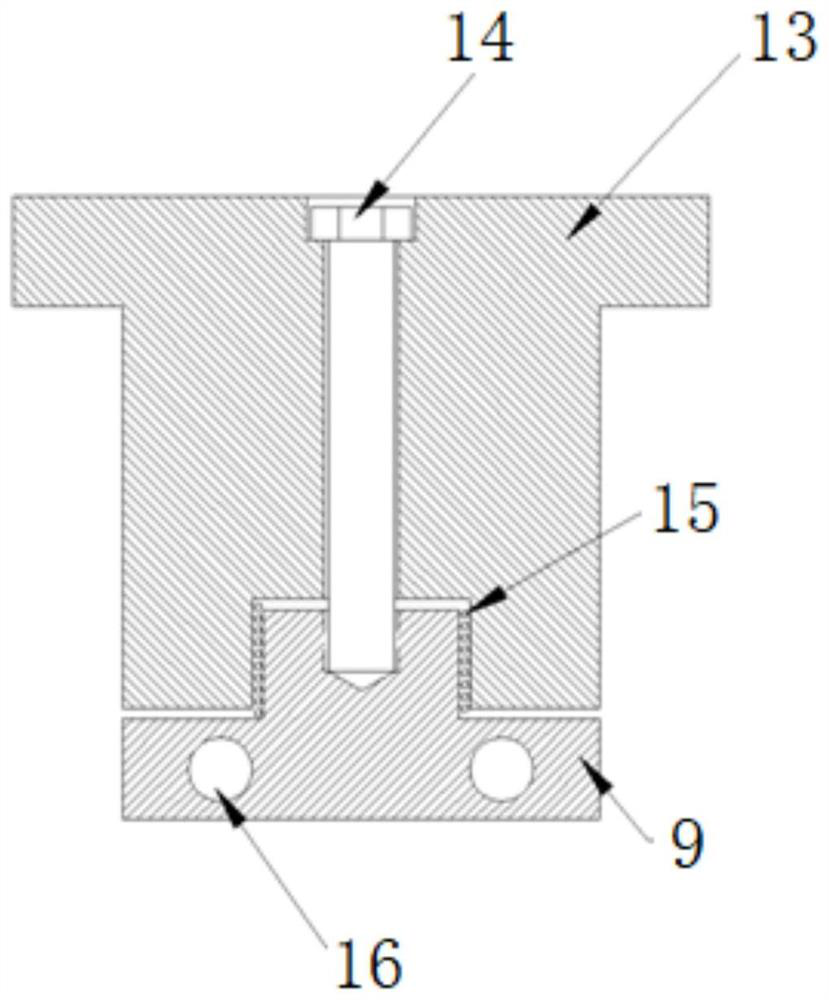

[0068] Start the motor, put the gate indenter and riser indenter into the gate and riser respectively, and set the pressure to 0.8MPa, keep the pressure for 5 minutes to promote feeding;

[0069] The upper mold and the lower mold are opened to obtain a 20% SiC / AHS-2 composite material casting.

Embodiment 2

[0071] A 40% SiC / AHS-2 composite material casting was prepared, and the middle layer was 2cm insulation cotton.

[0072] First, turn on the heaters at the gate and riser, and raise the temperature of the mold to 500°C to avoid blockage at the gate during filling;

[0073] After heating up, turn on the cooling water system of the lower mold, and pour the smelted 700°C composite material melt into the cavity, and stop casting when the melt starts to flow out from the riser;

[0074] Start the motor, place the gate indenter and riser indenter into the gate and riser respectively, and set the pressure to 0.5MPa, and keep the pressure for 10 minutes to promote feeding;

[0075] The upper mold and the lower mold are opened to obtain a 40% SiC / AHS-2 composite material casting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com