Casting method of large thin-walled valve body castings

A technology of steel castings and valve bodies, which is applied in the casting field of large thin-walled valve body steel castings, can solve the problems of large wood, consumption, and large manpower, and achieve the goals of improving production efficiency, meeting technical requirements, and reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

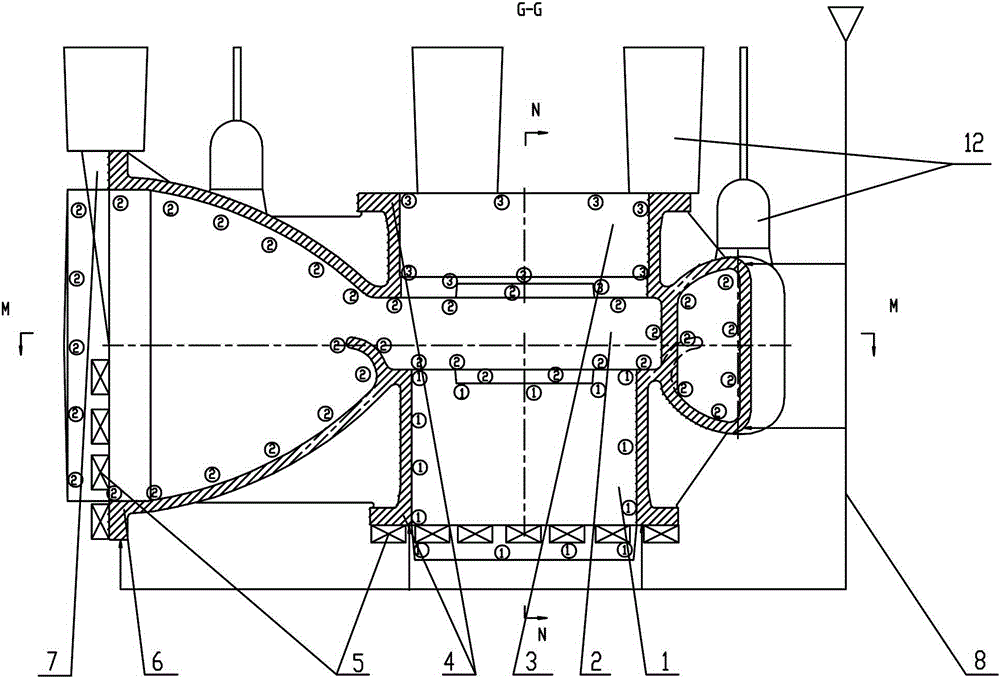

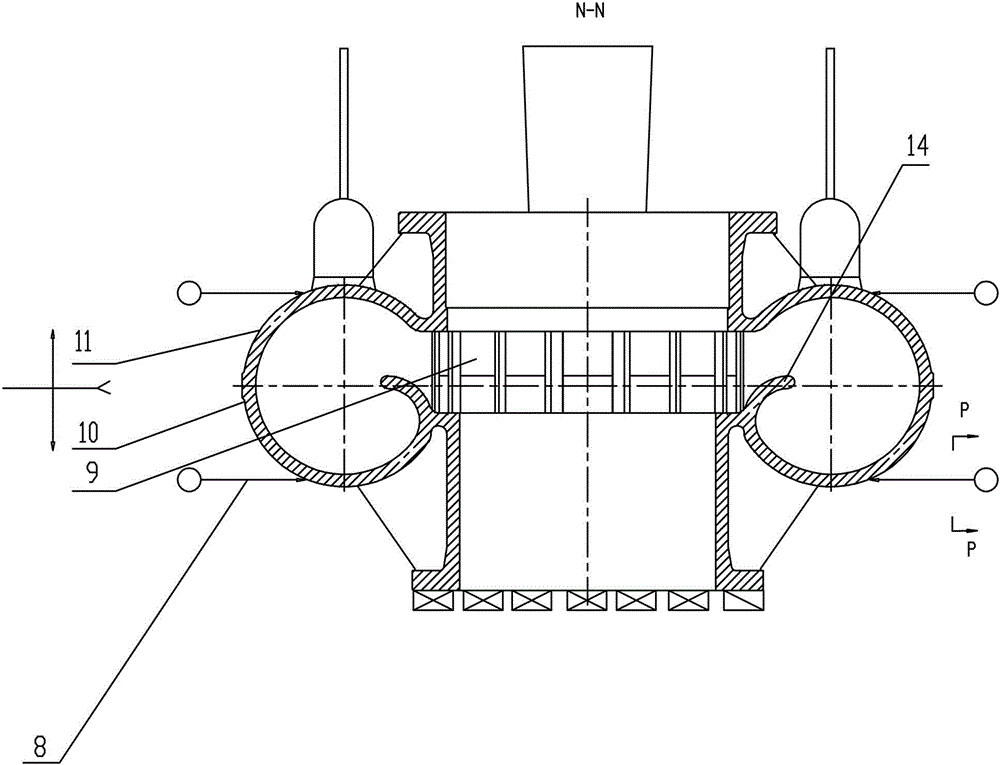

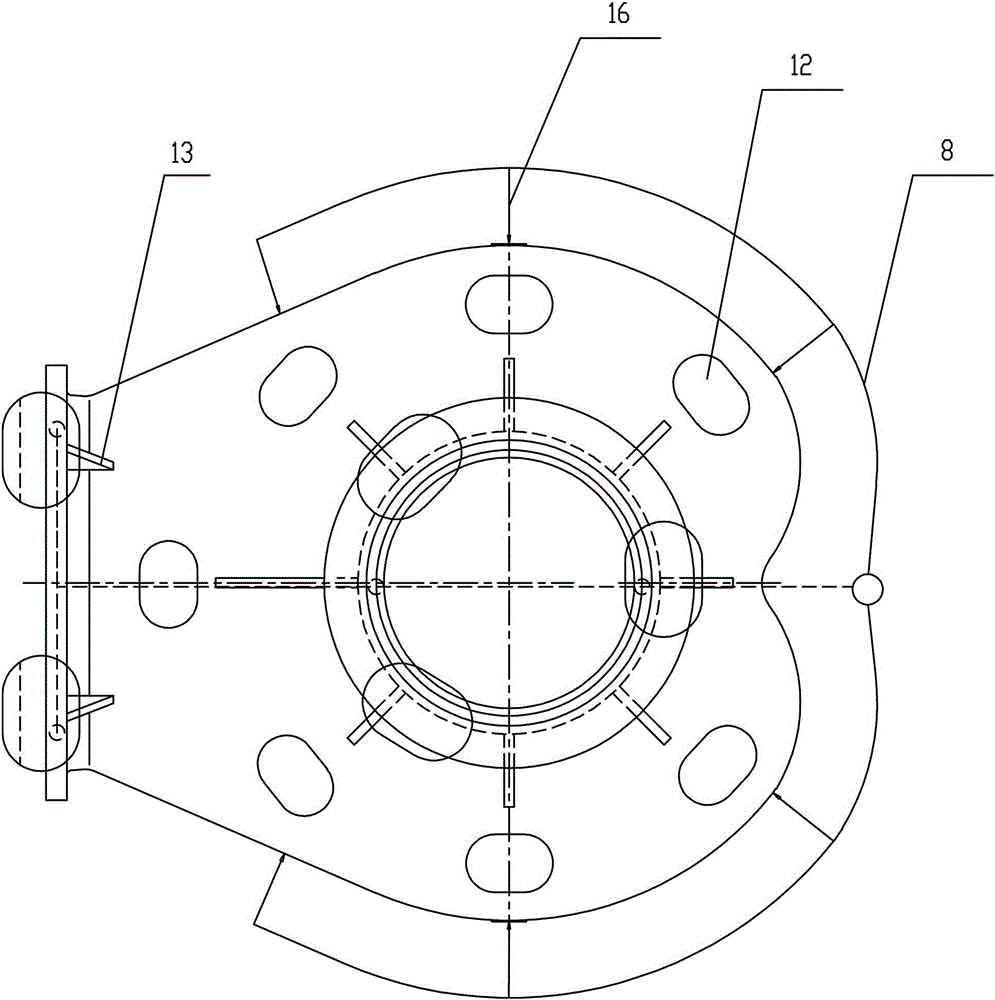

[0049] Such as Figure 1~6 Among them, a casting method of a large thin-walled valve body casting, comprising the following steps:

[0050] 1. Solid composite model making

[0051] The casting process is compiled according to the 650 hydraulic mechanical equipment valve body drawings, and the process diagram is as follows figure 1 , figure 2 , image 3 shown.

[0052] Use wood to make the overall skeleton of the upper half valve body 11, the outer mold of the lower half valve body 10, and the second core box 2 and irregular cross-section templates, fill the gap between the skeleton and the template with mixed fillers, tamp them, and repair the fillers smoothly After meeting the size requirements, it will harden naturally; the ratio of the model mixed filler is magnesia and sawdust in a volume ratio of 1:1, and the amount of magnesium chloride aqueous solution added is such that the mixture can be squeezed out by hand, and the original shape can be restored after letting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com