A coating alloy for repairing tungsten-based powder alloy die-casting mold and its preparation method

A die-casting mold and tungsten-based powder technology, applied in the field of material science and engineering, can solve the problems of poor material compatibility and bonding, small linear expansion coefficient, and high melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The method of the present invention is further specifically described by the examples given below.

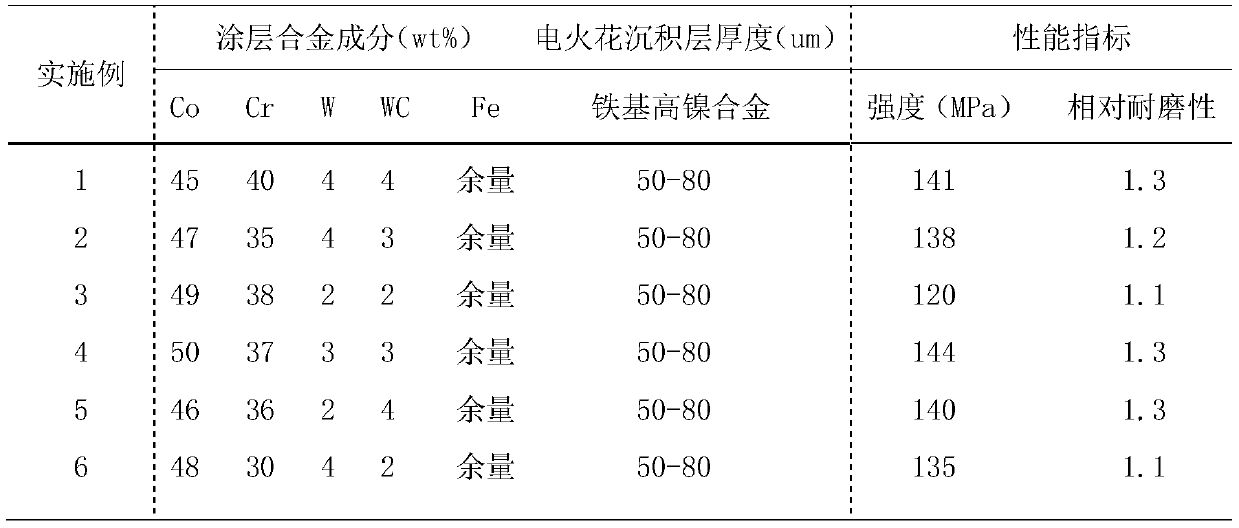

[0020] A kind of repairing tungsten-based powder alloy die-casting mold coating alloy and its preparation method described in the present invention are superimposed by various surface technologies, and first adopt electric spark deposition technology on the worn part of the working surface of the tungsten-based powder alloy die-casting mold cavity A layer of iron-based high-nickel alloy is deposited, and then a layer of wear-resistant coating alloy is deposited on the surface of the iron-based high-nickel alloy by using a high-energy-density laser beam. Wear-resistant coating alloy composition, by mass percentage (Wt / %): cobalt (Co): 45-50, chromium (Cr): 30-40%, tungsten (W): 2-4, tungsten carbide (WC) : 2-4, iron (Fe): balance.

[0021] A repairing tungsten-based powder alloy die-casting mold coating alloy and a preparation method thereof according to the present inve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com