Extraction method of procyanidine in grape seeds

A proanthocyanidin and extraction method technology, which is applied in the field of grape seed proanthocyanidin extraction, can solve the problems of low membrane flux, high cost investment, and low processing capacity, and achieve the effects of strong antioxidant activity, low cost input, and increased content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

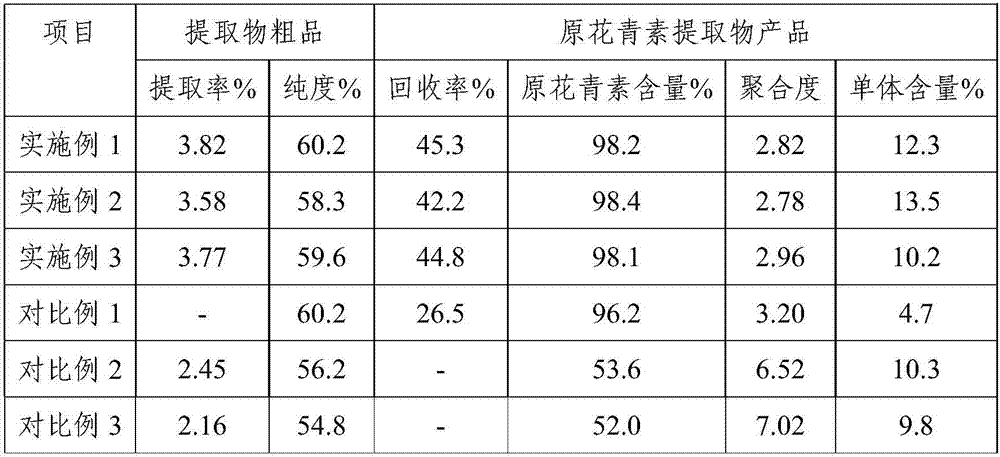

Examples

Embodiment 1

[0040] The present embodiment provides a kind of extraction method of grape seed proanthocyanidins, comprises the following steps:

[0041] 1) Grape seed pretreatment

[0042] Select non-mildew grape seeds, put them into the cleaning pool, wash them with sterile water for 3 times, drain or use dried grape seeds as raw materials, soak the dried grape seeds in sterile water for 2 hours to make them fully absorb water, Soak and rinse and drain. Put the drained grape seeds into the roller compactor, so that the grape seeds are crushed through a 1.0mm compaction gap. After being processed by the compactor, the grape seeds become flat, and the seed coat is crushed into several cracks. Endosperm exudation is clearly visible.

[0043] 2) Preparation of fermented grape seeds

[0044] a) Strain activation: Inoculate Aspergillus niger strains on a test tube slant or flat plate containing potato medium through sterility verification, and then cultivate the inoculated slant or flat plat...

Embodiment 2

[0058] The present embodiment provides a kind of extraction method of grape seed proanthocyanidins, comprises the following steps:

[0059] Wherein step 1)-step 2) is identical with embodiment 1.

[0060] 3) Preparation of proanthocyanidin extract

[0061] Three-level four-tank (tank body numbers are A, B, C, D) type countercurrent extraction method is adopted. The specific operation is to add 60 kg of fermented grape seeds to each tank, and add 85% ethanol solution with a pH of 4.5 (adjusting the pH with acetic acid) 200L was added to tank A, stirred and leached for 20 minutes at a temperature of 75°C to obtain extract A1, and store A1. Add the same amount of solvent into tank A, stir and extract under the same conditions for 15 minutes to obtain extract A2; then pump the extract A2 into tank B, and extract under the same extraction conditions to obtain Extract B1, store B1. Add the same amount of solvent into tank A, and extract under the same conditions. After the extracti...

Embodiment 3

[0065] The present embodiment provides a kind of extraction method of grape seed proanthocyanidins, comprises the following steps:

[0066] Wherein step 1)-step 4) is identical with embodiment 1.

[0067] 5) Refined proanthocyanidins

[0068] Soak the AB-8 macroporous resin in ethanol for 24 hours, rinse with ethanol until the effluent is mixed with distilled water without turbidity, and then rinse with distilled water until the effluent has no ethanol smell. Pack the pretreated adsorption resin into a column (the ratio of diameter to height of the chromatography column is 1:30), and the resin is required to be evenly dispersed and free of air bubbles. The crude product of proanthocyanidin was weighed and prepared into an aqueous solution with a concentration of 1.5%, filtered to remove insoluble impurities, and the proanthocyanidin solution was passed through a column. Desorb with 4 times the column volume of 25% (volume fraction) ethanol solution, collect the eluate and di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com