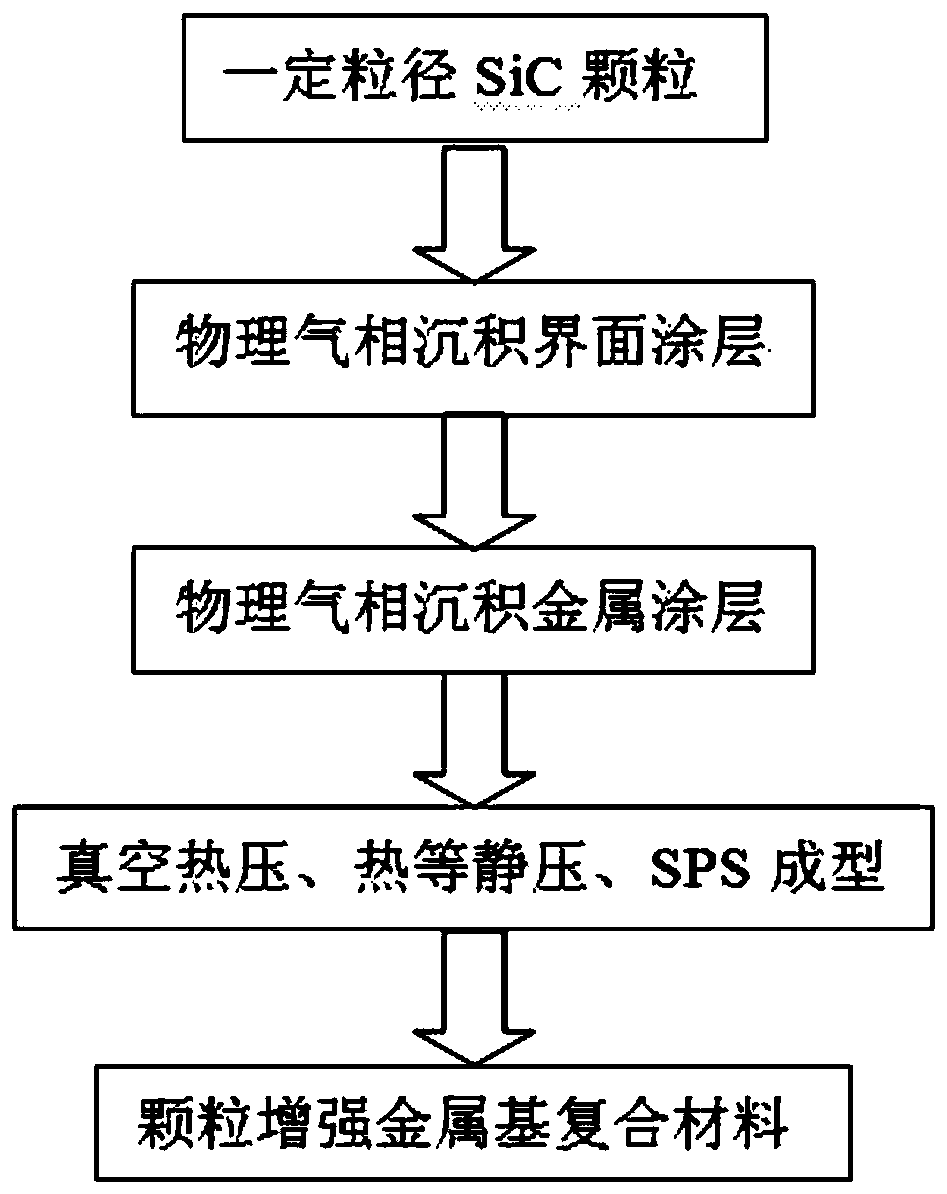

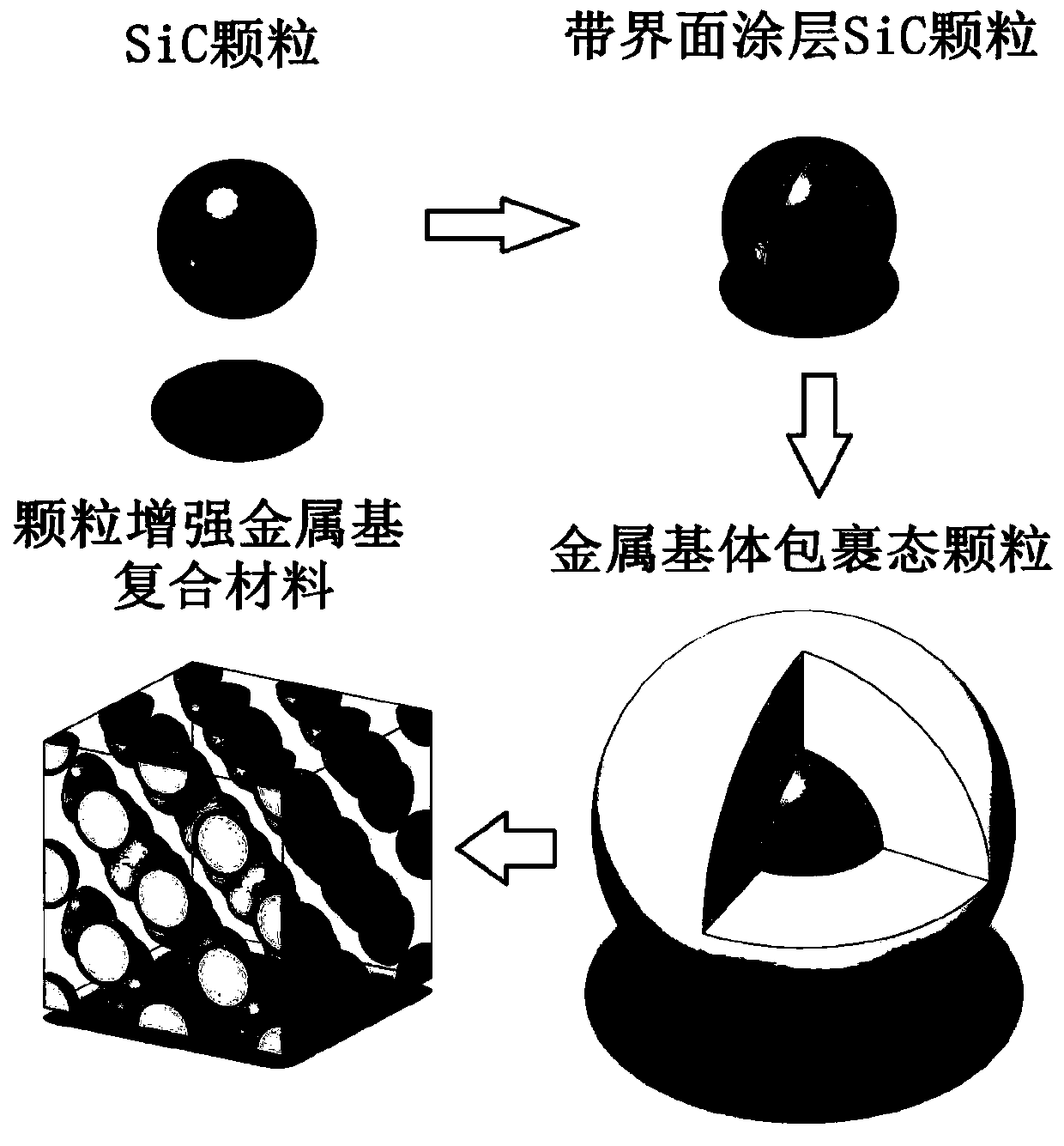

A method for preparing metal matrix composites with controllable volume fraction and highly dispersed particles

A particle-enhanced, volume-fraction technology, applied in metal material coating process, metal processing equipment, transportation and packaging, etc., can solve the problems of unevenness, high cost, low cost of discontinuous reinforcing agent, etc., achieve uniform distribution, prevent The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] SiC particles with a particle size of 20 μm are selected, and the method of physical vapor deposition is used to continuously vibrate and change the direction of the particles through the stirring method or vibration method. Using aluminum alloy target material, deposition temperature is 200°C, pressure is 0.8Pa, bias voltage is -100V, deposition rate is 10μm / h, deposition time is 5h, thickness of deposited aluminum alloy is 50μm, put the wrapped particles into the mold, and adopt vacuum hot pressing , the molding temperature is 500℃, the pressure is 80MPa, and the holding time is 5h, and the SiC particle-reinforced aluminum matrix composite material with a volume fraction of 2.7% is prepared.

Embodiment 2

[0038] Select SiC particles with a particle size of 100 μm, use the physical vapor deposition method, and use the stirring method or vibration method to continuously vibrate and change the direction of the particles, choose TiC as the target material, and inject Ar gas and CH 4 Gas, the ratio of the two is 60:15, the deposition temperature is 300°C, the pressure is 0.5Pa, the bias voltage is -300V, the deposition rate is 0.5μm / h, the deposition time is 4h, and the TiC coating of 2μm is deposited; TC17 titanium alloy is selected as the target material , the deposition temperature is 600°C, the pressure is 0.8Pa, the bias voltage is -200V, the deposition rate is 7.5μm / h, the deposition time is 4h, and the thickness of the deposited TC17 alloy is 30μm. 900 ℃, pressure 120MPa, heat preservation and pressure holding time 2h, SiC particle reinforced TC17 matrix composite material with a volume fraction of 39% was prepared.

Embodiment 3

[0040] Select SiC particles with a particle size of 50 μm, use the physical vapor deposition method, and use the stirring method or vibration method to continuously vibrate and change the direction of the particles, choose TiC as the target material, and inject Ar gas and CH 4 Gas, the ratio of the two is 60:2, the deposition temperature is 250°C, the pressure is 1Pa, the bias voltage is -400V, the deposition rate is 0.6μm / h, the deposition time is 2h, and the TiC coating of 1.2μm is deposited; TiAl alloy is selected as the target material. The deposition temperature is 600°C, the pressure is 0.8Pa, the bias voltage is -400V, the deposition rate is 10μm / h, the deposition time is 1h, the thickness of the deposited TiAl alloy is 10μm, the wrapped particles are put into the mold, and the forming temperature is 980°C. The pressure was 60MPa, and the holding time was 2h, and the SiC particle reinforced TiAl-based composite material with a volume fraction of 51% was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com