Preparation method and device for fiber reinforced metal matrix composite

A composite material and fiber-reinforced technology, which is applied in the field of spray deposition fiber-reinforced metal-matrix composite pipe preparation, can solve problems such as difficult to control the interface reaction between reinforcing fiber and metal matrix, difficult to prepare large-scale composite materials, and unfavorable performance of composite materials. Achieve fine microstructure, reduce oxygen content, and fast cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

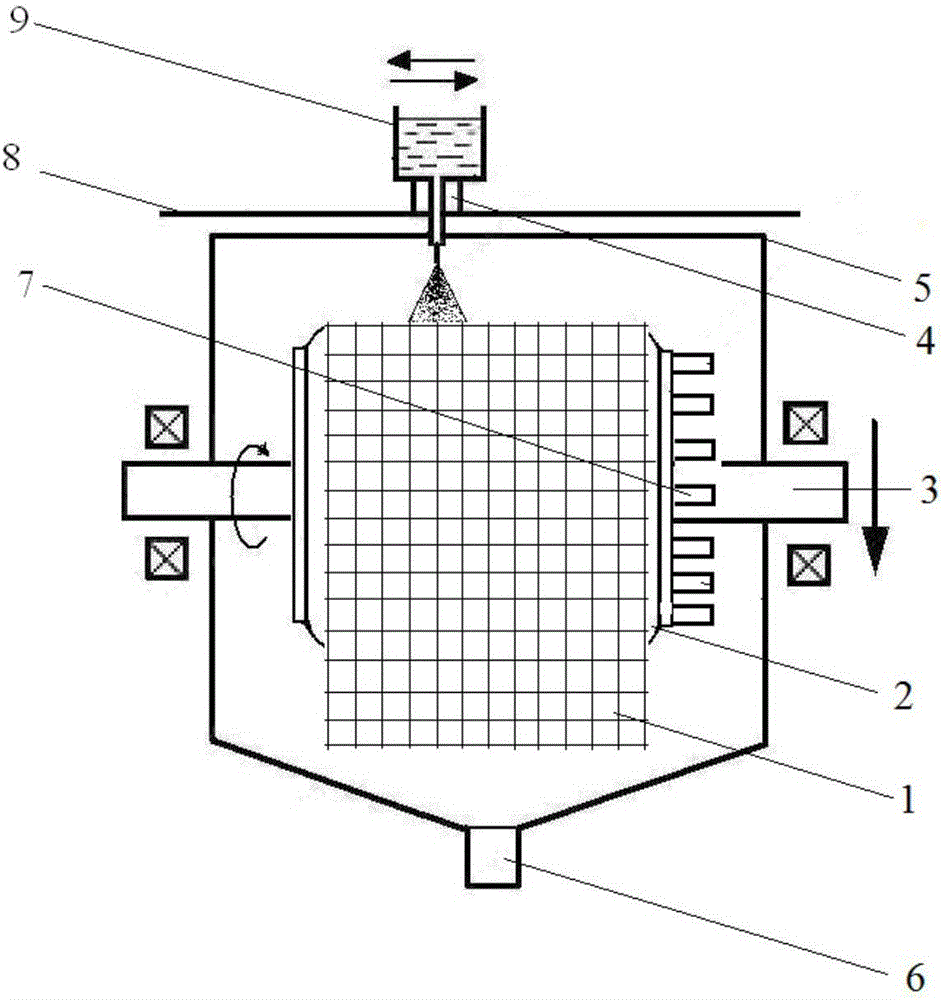

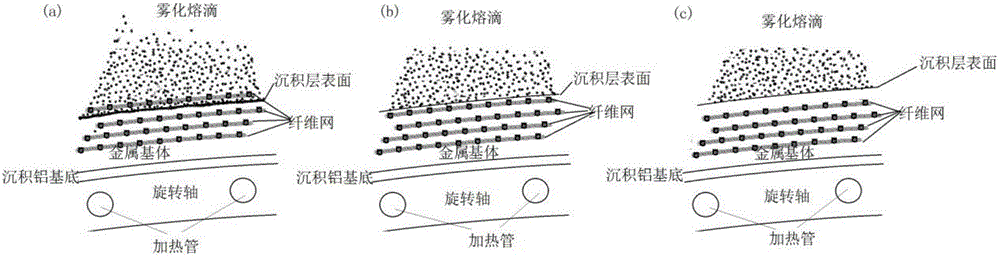

[0037]When using the preparation device of the present invention to prepare fiber-reinforced metal matrix composite materials, the metal or alloy is first melted, and the melting temperature is about 300-350° C. higher than the melting point of the alloy. The molten metal is scooped into a crucible coated with zinc oxide coating, and the crucible is preheated in advance; the bottom of the crucible is connected to a nozzle, and the inner diameter of the nozzle is 3.0-4.5mm. The nozzle is inserted into the atomizer, and the annular gap gas atomization method is adopted. The atomization gas pressure is 0.6-0.8MPa. It is atomized by nitrogen gas. The atomization cone angle is 30°. The high-pressure atomization gas is generated at the nozzle outlet. Negative pressure sucks out the molten metal in the crucible. When the molten metal is sucked out through the nozzle, it is hit and broken by the high-pressure atomizing gas and atomized into hundreds of micron metal droplets. The lower...

Embodiment 2

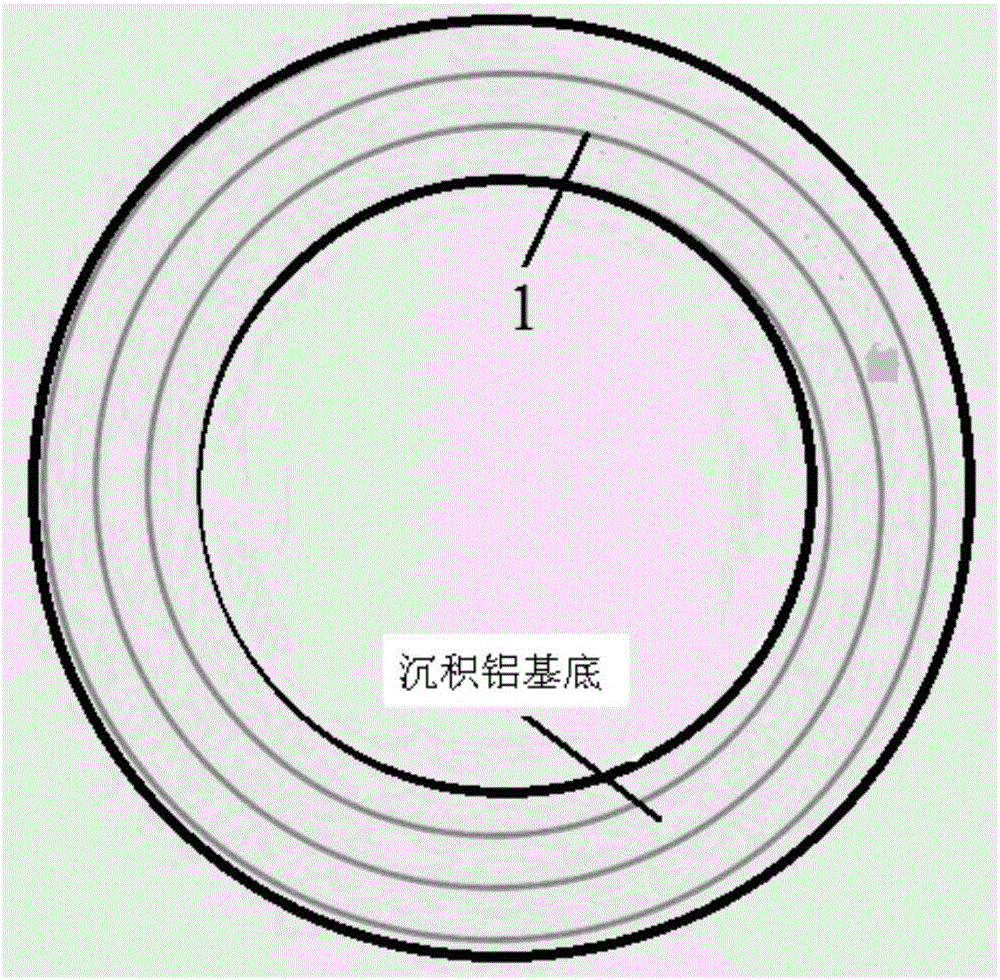

[0041] The fiber net used in this embodiment is a carbon fiber net with 1000 tows produced by Toray and a mesh hole of 5 mm × 5 mm. The crucible mobile multi-layer atomization deposition equipment is used, and Al-7Si alloy is used as the substrate. First, the matrix alloy is melted in a well-type furnace at a melting temperature of 980°C, which is about 320°C higher than the melting point of the alloy. The molten metal is scooped into the graphite crucible coated with zinc oxide coating on the surface to prevent the aluminum alloy solution from reacting with the graphite crucible. The graphite crucible has a volume of 1.5L. A graphite nozzle is connected to the bottom of the crucible, and the inner diameter of the nozzle is 3.2mm. The graphite nozzle is inserted into the atomizer. The atomizer is made of 30Cr alloy steel. It adopts the annular gap gas atomization method, the atomization gas pressure is 0.8MPa, and the atomization gas is atomized with nitrogen gas. The atomizi...

Embodiment 3

[0055] When the preparation device of the present invention is used to prepare C fiber reinforced aluminum matrix composite material plates:

[0056] The atomization pressure of the alloy melt is 0.8MPa, the atomization cone angle is 30°, and the deposition height is 200mm;

[0057] The carbon fiber tow of the C fiber mesh is 1000 per bundle, and the mesh is 5mm×5mm;

[0058] When using the above-mentioned fiber reinforced metal matrix composite material preparation device to prepare C fiber reinforced aluminum matrix composite material sheet, the heating temperature of the deposition base is 500 °C, and the temperature is kept for 30 minutes. The scanning period of the atomizer is 15 s. Rotate 4.8°, through the layer-by-layer deposition of aluminum alloy on the C fiber mesh, the aluminum matrix composite with uniform distribution of C fibers was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Axial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com