Dolutegravir film coated tablet preparation and preparation method thereof

A technology of film coating and dolutegravir, which is applied in the field of dolutegravir film-coated tablet formulation and its preparation, can solve the problems of high cost and achieve the effects of breaking the price monopoly, stable blood concentration and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

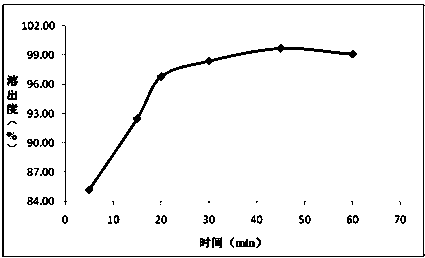

Image

Examples

Embodiment 1

[0043] Prescription composition: Prescription amount (mg / tablet)

[0044] Dolutegravir 50

[0045] Mannitol 314

[0046] Sodium carboxymethyl starch 32

[0047] Sodium stearyl fumarate 4

[0048] According to above-mentioned prescription quantity, preparation process is as follows:

[0049] (1) Material pretreatment: sieve dolutegravir, diluent, disintegrant, lubricant, and set aside;

[0050] (2) Mixing: Weigh the prescription amount of active drug dolutegravir, diluent, disintegrant, lubricant and mix evenly;

[0051] (3) Place the mixed powder in (2) in a dry granulator for granulation:

[0052] (4) Total mixing: Mix the dry granules prepared in (3) evenly with the prescribed amount of disintegrant and lubricant;

[0053] (5) Compress plain tablets: place the granules prepared in (4) in a high-speed rotary tablet press;

[0054] (6) Film coating: film-coat the qualified tablets prepared in (5).

Embodiment 2

[0056] Dolutegravir 50

[0057] Mannitol 314

[0058] Povidone 32

[0059] Sodium stearyl fumarate 4

[0060] According to above-mentioned prescription quantity, preparation process is as follows:

[0061] (1) Material pretreatment: sieve dolutegravir, diluent, disintegrant, lubricant, and set aside;

[0062] (2) Mixing: Weigh the prescription amount of active drug dolutegravir, diluent, disintegrant, lubricant and mix evenly;

[0063] (3) Place the mixed powder in (2) in a dry granulator for granulation:

[0064] (4) Total mixing: Mix the dry granules prepared in (3) evenly with the prescribed amount of disintegrant and lubricant;

[0065] (5) Compress plain tablets: place the granules prepared in (4) in a high-speed rotary tablet press;

[0066] (6) Film coating: film-coat the qualified tablets prepared in (5).

Embodiment 3

[0068] Dolutegravir 50

[0069] Microcrystalline Cellulose 314

[0070] Sodium carboxymethyl starch 32

[0071] Sodium stearyl fumarate 4

[0072] According to above-mentioned prescription quantity, preparation process is as follows:

[0073] (1) Material pretreatment: sieve dolutegravir, diluent, disintegrant, lubricant, and set aside;

[0074] (2) Mixing: Weigh the prescription amount of active drug dolutegravir, diluent, disintegrant, lubricant and mix evenly;

[0075] (3) Place the mixed powder in (2) in a dry granulator for granulation:

[0076] (4) Total mixing: Mix the dry granules prepared in (3) evenly with the prescribed amount of disintegrant and lubricant;

[0077] (5) Compress plain tablets: place the granules prepared in (4) in a high-speed rotary tablet press;

[0078] (6) Film coating: film-coat the qualified tablets prepared in (5).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com