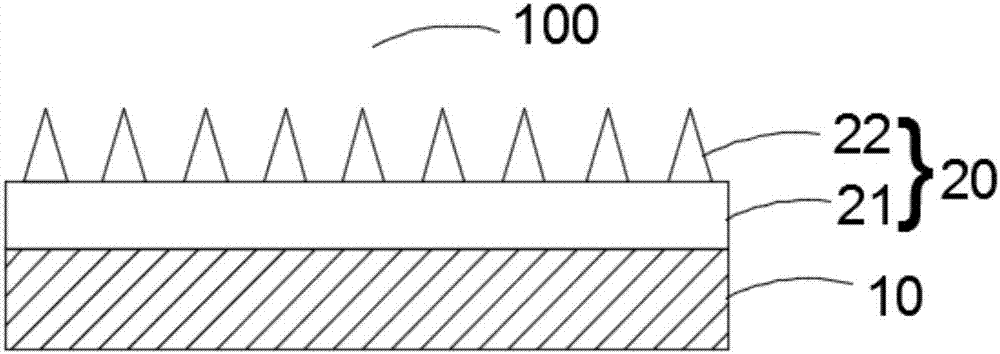

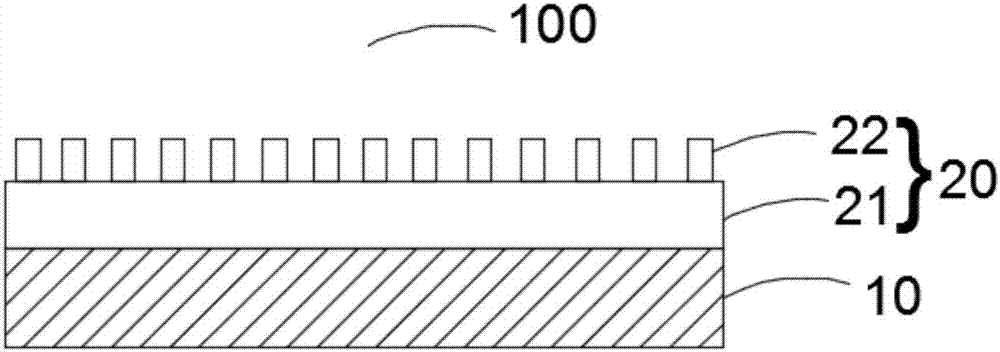

Nickel-boron-nitrogen co-doped diamond electrode as well as preparation thereof and application thereof

A diamond electrode and co-doping technology, applied in the field of electrochemistry, can solve the problems of unfavorable promotion and use, low energy utilization rate, easy deactivation, etc., and achieve strong electrocatalytic activity and physical and chemical stability, high catalytic activity and stable properties, high hydrogen evolution and oxygen evolution potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

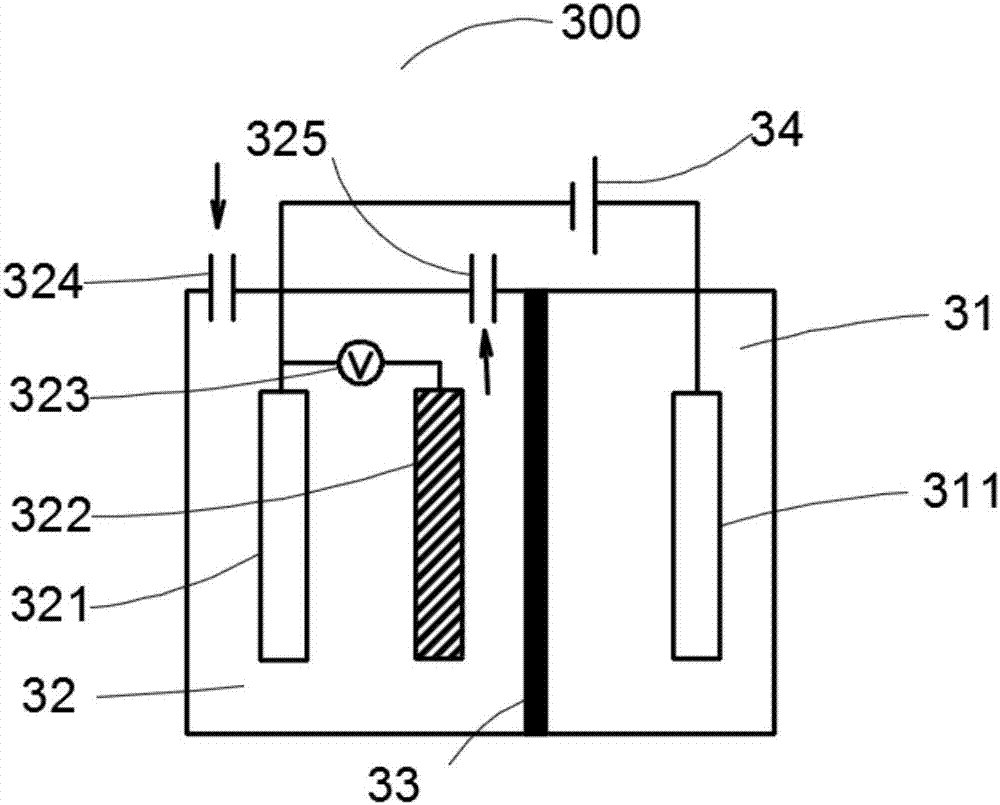

[0041] A method for preparing a nickel-boron-nitrogen co-doped diamond electrode, comprising:

[0042] (1) Take the metal titanium substrate, after sandblasting the metal titanium substrate, place it in acetone and alcohol for ultrasonic cleaning for 10 minutes, and then place the ultrasonic metal titanium substrate in a volume ratio of 1:15 with sulfuric acid and hydrogen peroxide pickling in the acid solution for 10min, after washing with water, place the metal titanium matrix in the suspension of nano-diamond powder for ultrasonic treatment for 1 hour for crystal planting, and then dry, wherein the average particle diameter of the suspension of diamond powder is 4nm, Zeta potential is about ±50mV.

[0043] (2) Using the hot wire chemical vapor deposition method, the metal titanium substrate after the crystal planting treatment is placed on the abutment, and the metal titanium substrate is kept in the middle of the hot wire and parallel to the hot wire, and the distance betw...

Embodiment 2

[0050] A method for preparing a nickel-boron-nitrogen co-doped diamond electrode, comprising:

[0051] (1) Take the silicon substrate, after sandblasting the silicon substrate, place it in acetone and alcohol for ultrasonic cleaning for 10 minutes, and then place the ultrasonic silicon substrate in a volume ratio of 1: (0.5-5): (1- 10) Rinse in a rinsing solution of hydrogen peroxide, ammonia water and deionized water for 5-15 minutes at a temperature of 80° C. After washing with water, place the silicon substrate in a suspension of nano-diamond powder for ultrasonic treatment for 1 hour The crystal is planted and then dried, wherein the average particle size of the diamond powder suspension is 5nm, and the Zeta potential is about ±55mV.

[0052] (2) Using the hot wire chemical vapor deposition method, place the silicon substrate after the crystal planting treatment on the abutment, keep the silicon substrate in the middle of the hot wire and parallel to the hot wire, and the ...

Embodiment 3

[0055] A method for preparing a nickel-boron-nitrogen co-doped diamond electrode, comprising:

[0056] (1) Take the niobium substrate, after sandblasting the silicon substrate, place it in acetone and alcohol for ultrasonic cleaning for 10 minutes, and then place the ultrasonic niobium substrate in a volume ratio of 1: (0.5-5): (1- 10) Rinse in a rinsing solution of hydrogen peroxide, ammonia water and deionized water for 5-15 minutes at a temperature of 80° C. After washing with water, place the niobium matrix in a suspension of nano-diamond powder for ultrasonic treatment for 1 hour The crystal is planted and then dried, wherein the average particle size of the diamond powder suspension is 5nm, and the Zeta potential is about ±55mV.

[0057](2) Using the hot wire chemical vapor deposition method, place the niobium substrate after the crystal planting treatment on the abutment, keep the niobium substrate in the middle of the hot wire and parallel to the hot wire, and the dist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com