Poly-(3-hydroxybutyrate-3-hydroxyhexanoate)corn fiber glue plant fiber fully-degraded composite material

A corn viscose and hydroxycaproate technology is applied in the field of polycorn viscose plant fiber fully degradable composite material and its preparation, which can solve the problems of high brittleness, poor hydrophilicity and high cost, and achieve strong toughness and adhesion. High, brittleness improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

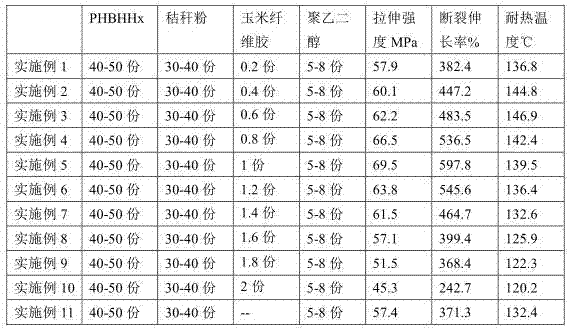

Examples

Embodiment 1

[0017] A poly(3-hydroxybutyrate-3-hydroxyhexanoate) corn viscose plant fiber fully degradable composite material is prepared from the following raw materials in parts by weight: PHBHHx40-50 parts, 30-40 parts of straw powder, 0.2 part of corn fiber glue, and 5-8 parts of polyethylene glycol.

[0018] In an embodiment of the present invention, the particle size of the straw fiber powder is 60 mesh.

[0019] In the embodiment of the present invention, the raw materials: PHBHHx (Dongguan Yingsheng Plastic Chemical Co., Ltd.), straw powder (Shaanxi Jinhe Agricultural Technology Co., Ltd.), corn fiber glue (Shanghai Aladdin Biochemical Technology Co., Ltd. ), polyethylene glycol (Xingtai Xinlanxing Technology Co., Ltd.).

[0020] In the embodiment of the design of the present invention, the main instruments and equipment involved: constant temperature blast drying oven: SXG-025 type (Shanghai Huanjing Test Equipment Factory); three-dimensional mixer (Changzhou Rihong Drying Equipm...

Embodiment 2

[0031] A poly(3-hydroxybutyrate-3-hydroxyhexanoate) corn viscose plant fiber fully degradable composite material is prepared from the following raw materials in parts by weight: PHBHHx 40-50 parts , 30-40 parts of straw powder, 0.4 part of corn viscose, and 5-8 parts of polyethylene glycol.

[0032] In an embodiment of the present invention, the particle size of the straw fiber powder is 60 mesh.

[0033] In the embodiment of the present invention, the raw materials: PHBHHx (Dongguan Yingsheng Plastic Chemical Co., Ltd.), straw powder (Shaanxi Jinhe Agricultural Technology Co., Ltd.), corn fiber glue (Shanghai Aladdin Biochemical Technology Co., Ltd. ), polyethylene glycol (Xingtai Xinlanxing Technology Co., Ltd.).

[0034] In the embodiment of the design of the present invention, the main instruments and equipment involved: constant temperature blast drying oven: SXG-025 type (Shanghai Huanjing Test Equipment Factory); three-dimensional mixer (Changzhou Rihong Drying Equipme...

Embodiment 3

[0045] A poly(3-hydroxybutyrate-3-hydroxyhexanoate) corn viscose plant fiber fully degradable composite material is prepared from the following raw materials in parts by weight: PHBHHx 40-50 parts , 30-40 parts of straw powder, 0.6 part of corn viscose, and 5-8 parts of polyethylene glycol.

[0046] In an embodiment of the present invention, the particle size of the straw fiber powder is 60 mesh.

[0047] In the embodiment of the present invention, the raw materials: PHBHHx (Dongguan Yingsheng Plastic Chemical Co., Ltd.), straw powder (Shaanxi Jinhe Agricultural Technology Co., Ltd.), corn fiber glue (Shanghai Aladdin Biochemical Technology Co., Ltd. ), polyethylene glycol (Xingtai Xinlanxing Technology Co., Ltd.).

[0048] In the embodiment of the design of the present invention, the main instruments and equipment involved: constant temperature blast drying oven: SXG-025 type (Shanghai Huanjing Test Equipment Factory); three-dimensional mixer (Changzhou Rihong Drying Equipme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com