A kind of stabilization method of organic nanostructure

A nano-structure and organic technology, applied in the field of organic polymer and nano-material science, can solve the problems that there are no relevant reports on the stabilization of organic nano-structures, and achieve long-term non-destructive preservation, simple operation process and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029]

[0030] 1. Preparation of phase separation structure:

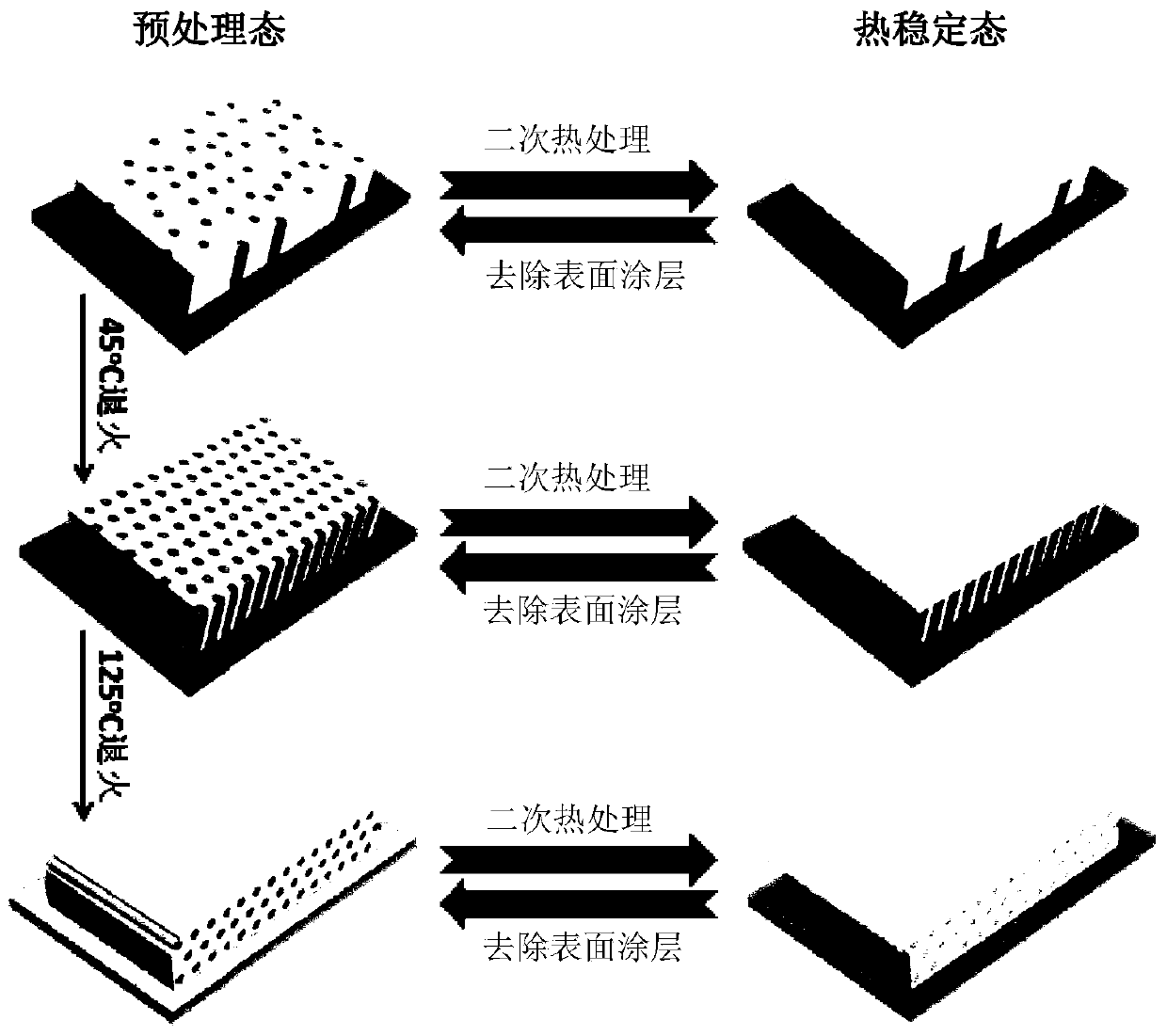

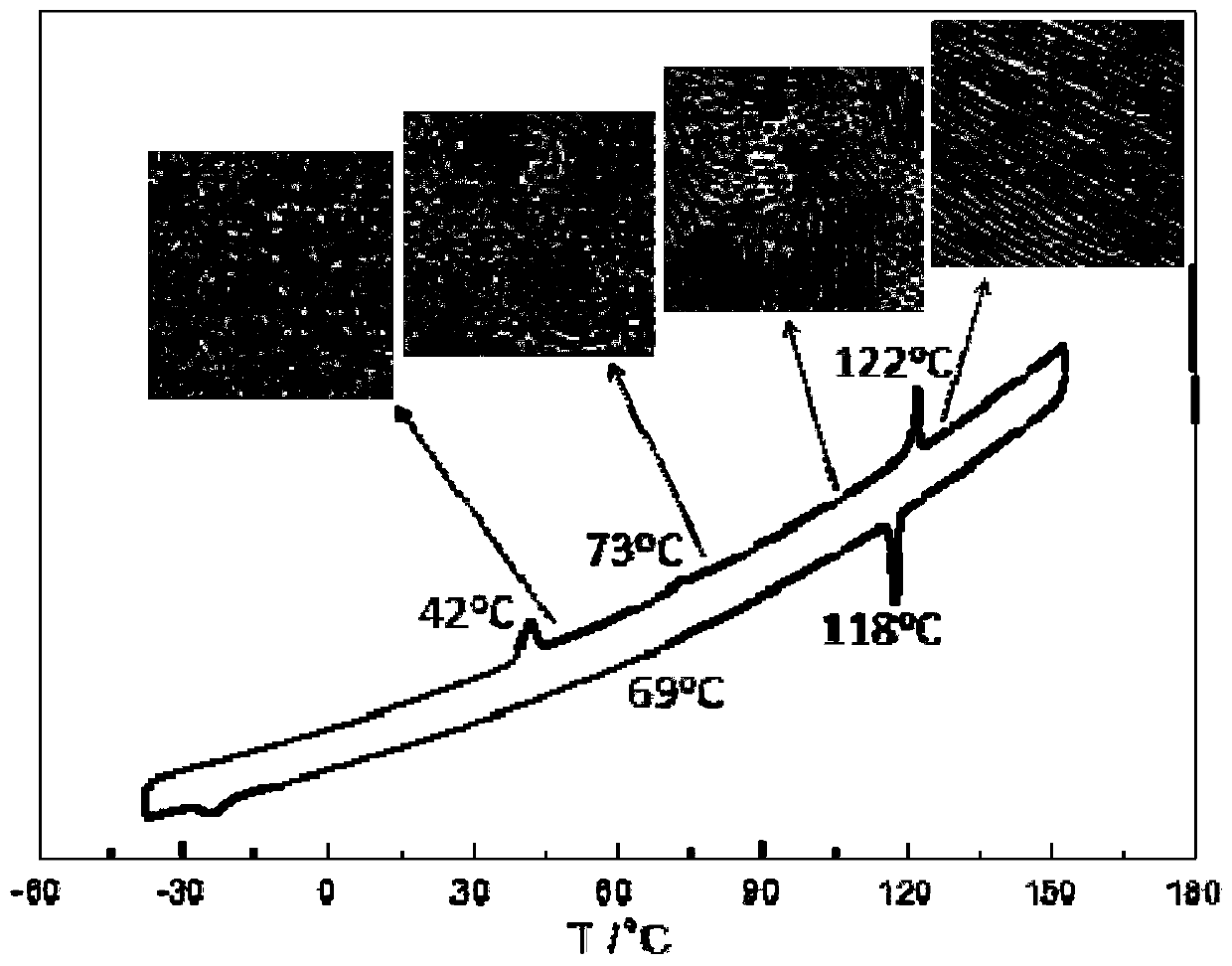

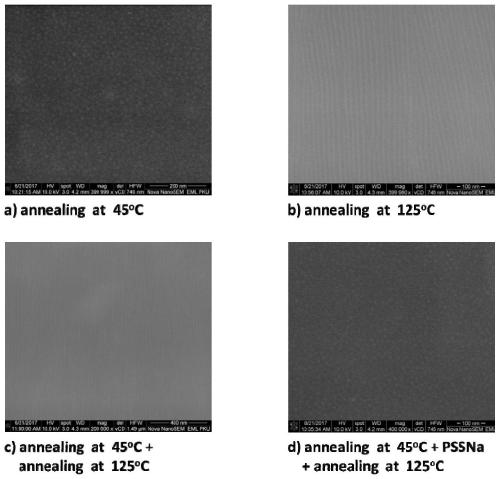

[0031] Dissolve the block copolymer A-b-C represented by formula I a) in a good organic solvent such as toluene or tetrahydrofuran to obtain a clear homogeneous solution. After the copolymer is fully dissolved, filter the solution, and use spin coating, rod coating or dipping The filtrate is evenly coated on the clean substrate by pulling and other methods to form a copolymer film. After the thin film is annealed at different temperatures, regular and ordered nano phase separation structures with different morphologies can be obtained. The nanopillars formed by the dispersed phase generally have a diameter of 5-50nm, a length of 20nm-20μm, and a period of 10-100nm, or form an in-plane arrangement parallel to the substrate, which is displayed as a striped morphology in the AFM phase diagram; Or form an out-of-plane arrangement perpendicular to the substrate, which is displayed as a dot-like morphology in the AF...

Embodiment 2

[0041]

[0042] 1, the preparation of phase separation structure: adopt the block copolymer PEO-b-PM in formula II a) 11 AzPy prepares the copolymer film, and the preparation method is the same as that of Example 1.

[0043] 2. Stabilization of nanopatterns by surface coating: except that polyvinylpyrrolidone (PVP) in formula II b) is used instead of the water-soluble polymer used for the surface coating, the others are the same as in Example 1.

[0044] 3. Long-term non-destructive storage of samples: the same as in Example 1.

[0045] 4. Preparation of complex nano-patterns: the same as in Example 1.

Embodiment 3

[0047]

[0048] 1. Preparation of phase-separated structure: the copolymer film was prepared by using the block copolymer PS-b-PNIPAAm in formula III a), and the preparation method was the same as that in Example 1.

[0049] 2. Stabilization of nanopatterns by the surface coating: except that the water-soluble polymer used in the surface coating is replaced by polyethylene oxide (PEO) in formula III b), the others are the same as in Example 1.

[0050] 3. Long-term non-destructive storage of samples: the same as in Example 1.

[0051] 4. Preparation of complex nano-patterns: the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com