Adhesive composition comprising ionic antistatic agent

A technology of antistatic agent and composition, which is applied in the field of adhesive composition, and can solve problems such as bleeding, excessive antistatic performance, and reduced durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

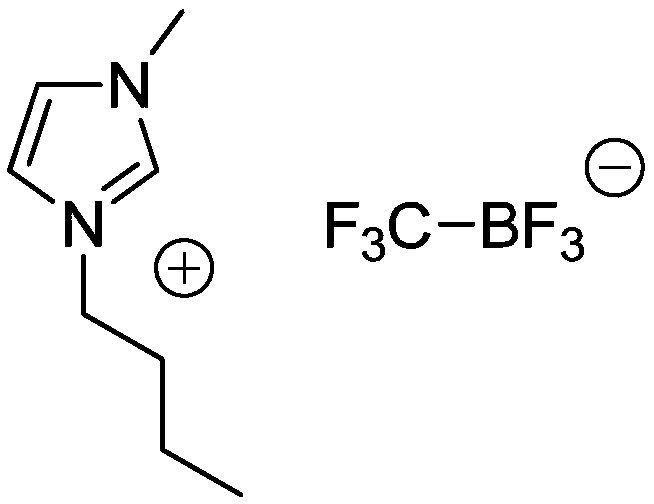

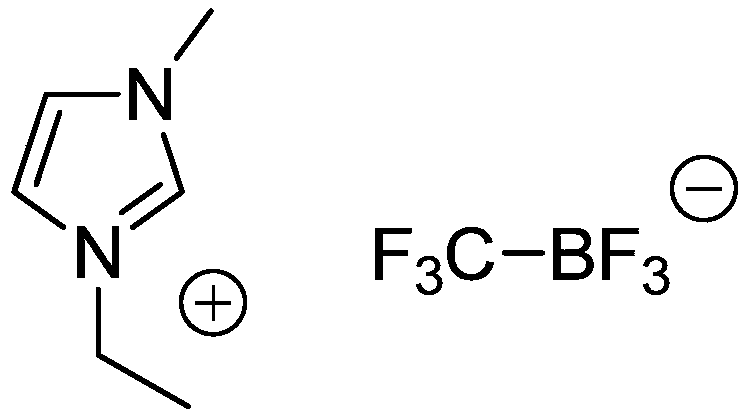

Problems solved by technology

Method used

Image

Examples

manufacture example

[0112] Production example: Production of acrylic copolymer

[0113] Into a 1L reactor with refluxing nitrogen gas and equipped with a cooling device in a way that can easily adjust the temperature, was charged with 90 parts by weight of n-butyl acrylate, 7 parts by weight of methacrylate, and 2 parts by weight of 2-hydroxyethyl acrylate. , 1 part by weight of acrylic acid monomer mixture, and then put in 100 parts by weight of ethyl acetate as a solvent. After that, it was purged with nitrogen for 1 hour to remove oxygen, and then maintained at 62°C. After the above mixture was uniformly mixed, 0.07 parts by weight of azobisisobutyronitrile (AIBN) as a reaction initiator was added and reacted for 8 hours to produce an acrylic copolymer (weight average molecular weight approximately 1,000,000).

Embodiment

[0115] (1) Manufacturing of adhesive composition

[0116] An adhesive composition having the composition and content described in Table 1 below was produced.

[0117] (2) Manufacturing of adhesive sheet

[0118] After the adhesive composition is manufactured, it is applied to a film coated with a silicon release agent and dried at 100°C for 1 minute to form an adhesive layer of 25 μm.

[0119] Then, the release film was laminated on the adhesive layer to produce an adhesive sheet.

[0120] (3) Manufacturing of polarizing plate with adhesive

[0121] After the release film of the produced adhesive sheet was peeled off, the adhesive layer was laminated on an iodine-based polarizing plate containing a TAC protective film with a thickness of 185 μm to produce an adhesive-attached polarizing plate.

[0122] [Table 1]

[0123]

[0124]

[0125]

experiment example

[0127] The adhesive compositions of the Examples and Comparative Examples were applied to a release film coated with a silicon release agent so that the thickness after curing was 25 μm, and dried at 100° C. for 1 minute to form an adhesive layer.

[0128] After that, the adhesive layer produced as described above was laminated on both sides of an iodine-based polarizing film (total thickness of 185 μm) to which triacetyl cellulose-based protective films were bonded by an adhesive process to produce a polarizing plate. The manufactured polarizing plate was stored under the conditions of 23°C and 60% RH for 7 days.

[0129] (1) Heat resistance evaluation

[0130] The release film of the polarizing plate manufactured above was removed and joined to Corning Glass. After autoclave treatment, it was placed at a temperature of 60°C for 300 hours, and then the occurrence of bubbles or peeling was observed and evaluated. The evaluation was carried out after the above heat treatment and befo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com