Method for uniformly doping surface of material with metal ions, and product thereof, and application of product

A metal ion, surface uniform technology, applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of low charge transport capacity, conductivity of electrode materials, reduction of electrochemical characteristics of rate performance, etc., to achieve reduction and side effects Effects of reaction, improvement of surface stability, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] As mentioned above, the present invention provides a preparation method for uniformly doping metal ions on the surface of a material, comprising the following steps:

[0060] 1) First, the precipitation-thermal infiltration reaction is used to disperse the material, the precursor of the metal ion and the precipitant into the solvent, heat and stir, and construct a metal nano-deposition layer on the surface of the material to obtain an intermediate product;

[0061] 2) Then, the intermediate product prepared in step 1) is heat-treated to infiltrate and dope metal ions in a certain thickness range on the surface of the material to obtain a metal doped layer with a nano-layer thickness on the surface of the material.

[0062] In the present invention, the thickness of the uniform deposition layer can be controlled by controlling parameters such as the deposition time, reaction temperature, and subsequent calcination temperature and time of the metal ion precursor during the...

Embodiment 1

[0070] 1. Preparation of Surface Co-doped LiNiMnO

[0071] In a flask, add spinel-type lithium nickel manganate 1g LiNi 0.5 Mn 1.5 O 4 Powder, 0.1 g of cobalt metal precursor cobalt acetate tetrahydrate, and 0.1 g of precipitant urea were dispersed in 30 ml of water to obtain a reaction system. In the reaction system, the concentration of the spinel-type lithium nickel manganate is 33.3 g / L; the concentration of the cobalt acetate tetrahydrate is 2×10 -2 mol / L; the concentration of the urea is 2.5×10 -3 mol / L. The reaction was stirred at 80 °C for 8 h, and the intermediate product was obtained by centrifugation, washing and drying.

[0072] The intermediate product was heated to 700°C at a rate of 5°C / min, calcined at this temperature for 2 h, and then cooled to room temperature to obtain spinel-type lithium nickel manganate powder with a nano-layer cobalt-doped surface on the surface. Its base material is spinel-type lithium nickel manganate LiNi 0.5 Mn 1.5 O 4 , the...

Embodiment 2

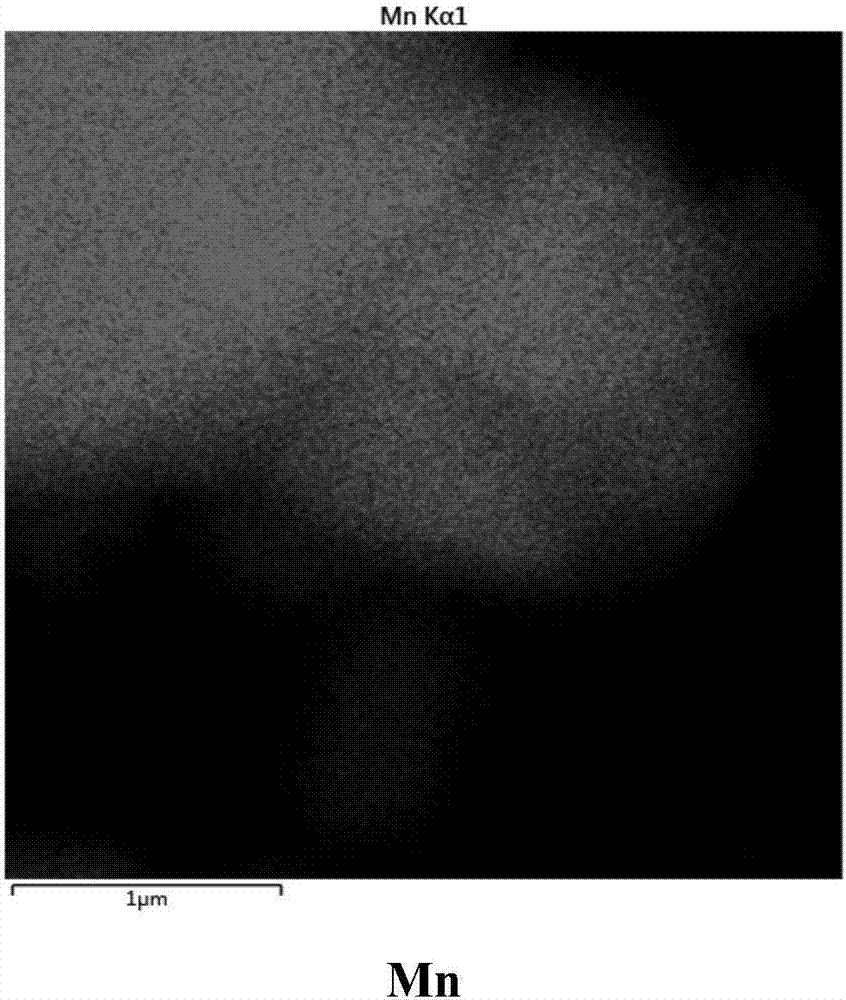

[0083] 1. Preparation of Surface Manganese-Doped LiNiMnO

[0084] In a flask, add spinel-type lithium nickel manganate 1g LiNi 0.5 Mn 1.5 O 4 Powder, 0.1 g of manganese metal manganese precursor manganese acetate tetrahydrate, and 0.1 g of precipitant urea were dispersed in 30 ml of water to obtain a reaction system. In the reaction system, the concentration of the spinel-type lithium nickel manganate is 33.3g / L; the concentration of the manganese acetate tetrahydrate is 2×10 -2 mol / L; the concentration of the urea is 2.5×10 -3 mol / L. The reaction was stirred at 80 °C for 8 h, and the intermediate product was obtained by centrifugation, washing and drying.

[0085] The intermediate product was heated to 700°C at a rate of 5°C / min, calcined at this temperature for 2 h, and then cooled to room temperature to obtain spinel-type lithium nickel manganate powder with nano-layer manganese doped on the surface. Its base material is spinel-type lithium nickel manganate LiNi 0.5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com