Multi-channel horizontal high-voltage device

A horizontal high-voltage, multi-channel technology, applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of rising on-resistance and limiting applications, and achieve reduced on-resistance, increased number of channels, and small on-resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

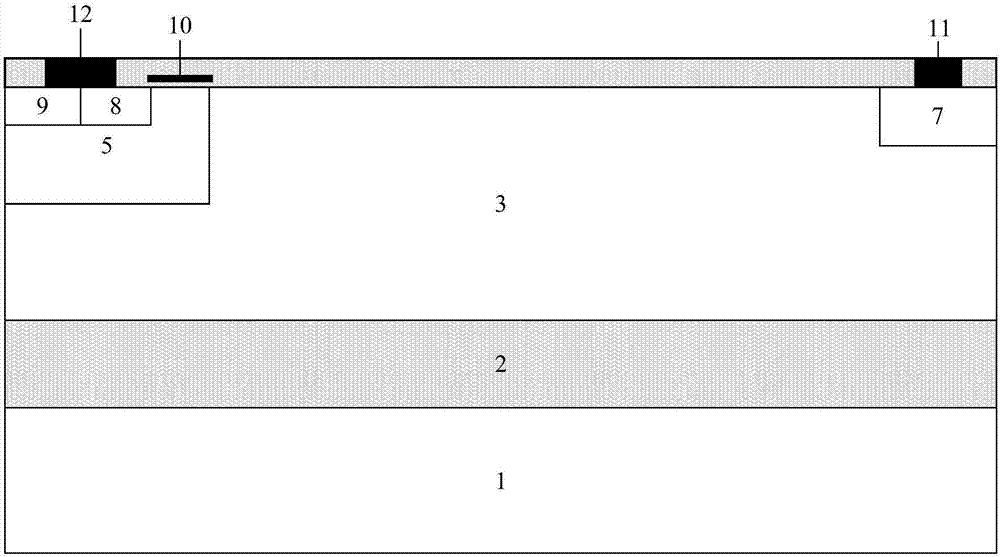

[0020] Such as figure 2 As shown, a multi-channel lateral high voltage device whose cell structure is integrated on a semiconductor substrate 1 of a first conductivity type includes a buried oxide layer 2 arranged on the upper end surface of the substrate 2 and a buried oxide layer 2 arranged above the buried oxide layer 2. The second conductivity type semiconductor drift region 3, the trench structure 4 arranged on the left and outside of the second conductivity type semiconductor drift region 3, the second conductivity type semiconductor drain region 7 on the right inside the second conductivity type semiconductor drift region 3, the second conductivity type semiconductor drift region 3 The inside of the second conductivity type semiconductor drift region 3 is adjacent to the first conductivity type semiconductor body region 5 on the right side of the trench structure 4, the second conductivity type semiconductor source region 8 located inside the first conductivity type semic...

Embodiment 2

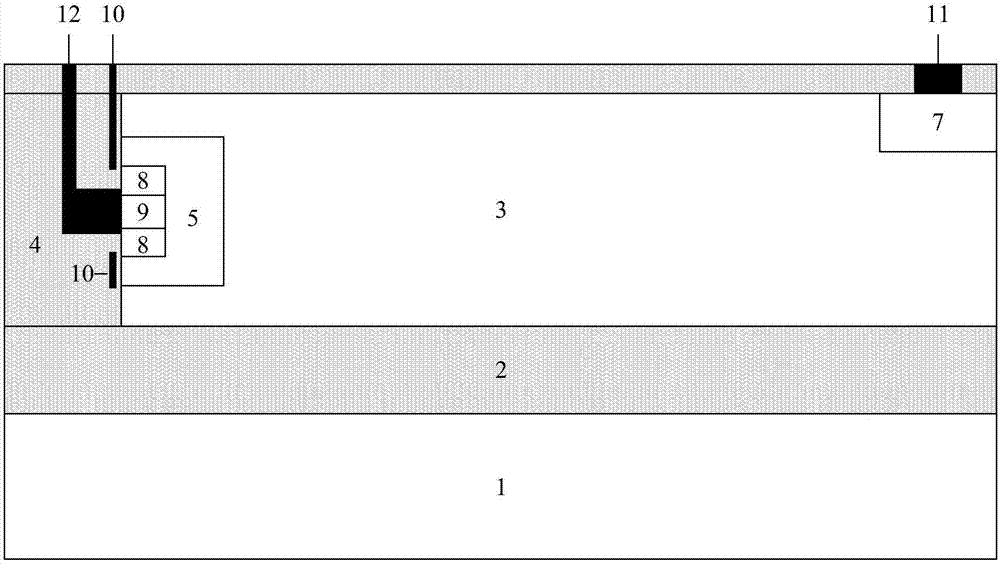

[0023] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that each metal gate is connected to each other inside the device.

Embodiment 3

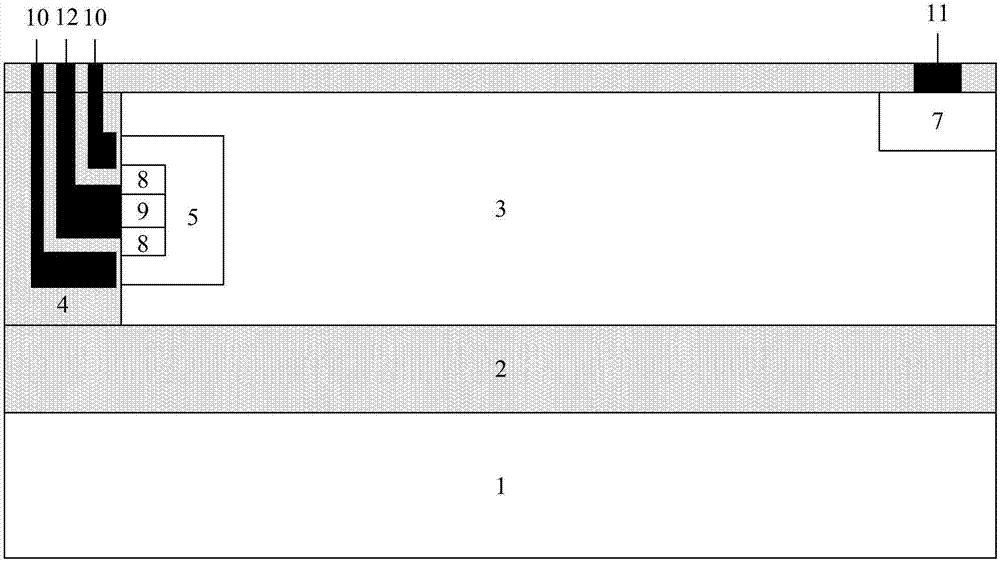

[0025] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the device includes two body region units, the multi-gate metal structure 10 includes three metal gates led from the surface of the device into the trench structure 4, and the multi-gate metal The structure 10 provides 4 channels in the first conductivity type semiconductor body region 5, and each metal gate is led to the device surface through a through hole, thereby forming a three-gate four-channel device structure, which greatly reduces the device The specific on-resistance.

[0026] In addition, in each embodiment, the second conductivity type semiconductor drain region 7 can be replaced with a first conductivity type semiconductor, thereby forming a LIGBT structure.

[0027] In each embodiment, the substrate material is SOI substrate or bulk silicon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com