Environment-friendly energy-saving high-conversion-ratio rare-earth catalyst and preparation method thereof

A rare earth catalyst, high conversion rate technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of high wear rate and high cost of tail gas treatment, Achieve the effects of prolonging the service life, solving the exhaust emission problem, and stabilizing the lattice structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

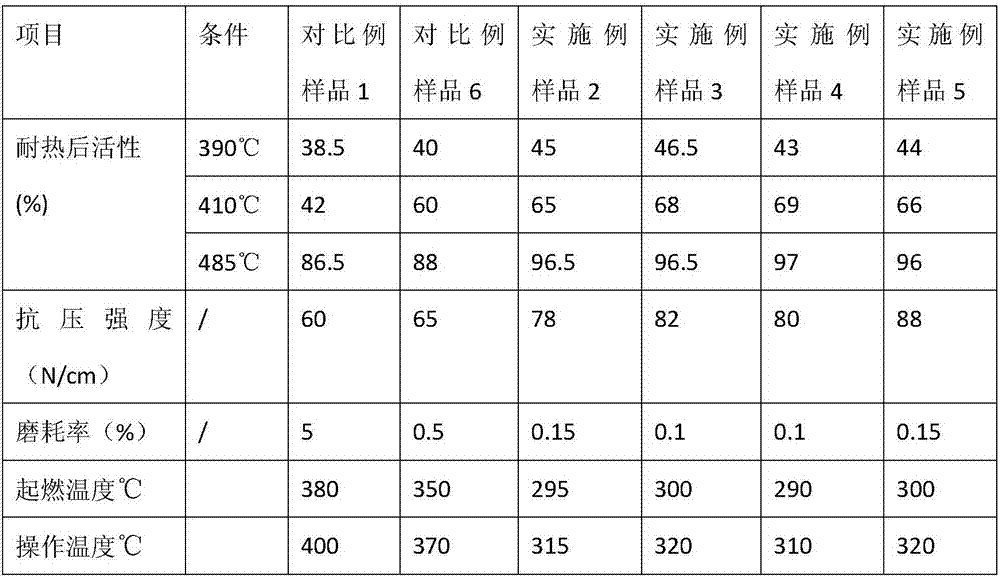

Examples

Embodiment 1

[0037] Weigh 2.5gLa(NO 3 ) 3 ﹒ 6H 2 O, 2.5gCe(NO 3 ) 3 ﹒ 6H 2 O, 2.5gNd(NO 3 ) 3 ﹒ 6H 2 O, 2.5gPr(NO 3 ) 3 ﹒ 6H 2 O was added to 400mL of distilled water, 150g of refined diatomaceous earth was added after complete dissolution, stirred for 30min, vacuum steamed at 60℃ for 12h, roasted at 400℃ for 4h to obtain material b; 2 O 5 , 10g KOH is fully dissolved in the same reaction tank, after mixing evenly, 2.5g organic polymer compound (polyethylene glycol 8000) and 2.5g surfactant (hexadecyltrimethylammonium bromide) are added to fully react to obtain KVO 3 Or NaVO 3 Solution, take 200mL, add 60mL dilute sulfuric acid (mass concentration 25%), react to form a uniform solution, add it to material b, and add 10gCs 2 SO 4 , 2.5g of thiosulfate, 2.5g of sodium sulfate, 2.5mL of phosphoric acid (mass concentration of 85%), 7.5 sulfur (fineness of 20 mesh) into the mill for full mixing for 0.5 hours. The mixed and milled materials are mechanically shaped, and then dried at 150°C to mak...

Embodiment 2

[0039] Weigh 5gLa(NO 3 ) 3 ﹒ 6H 2 O, 5gCe(NO 3 ) 3 ﹒ 6H 2 O, 5gNd(NO 3 ) 3 ﹒ 6H 2 O, 5gPr(NO 3 ) 3 ﹒ 6H 2 O was added to 400mL of distilled water, 150g of refined diatomaceous earth was added after complete dissolution, stirred for 30min, vacuum steamed at 60℃ for 12h, roasted at 400℃ for 4h to obtain material b; 2 O 5 , 10g KOH is fully dissolved in the same reaction tank, after mixing evenly, 2.5g organic polymer compound (polyvinylpyrrolidone PVPK15) and 2.5g surfactant (hexadecyltrimethylammonium chloride) are added to fully react to obtain KVO 3 Or NaVO 3 Solution, take 200mL, add 60mL dilute sulfuric acid (mass concentration 25%), react to form a uniform solution, add it to material b, and add 10gCs 2 SO 4 , 2.5g of thiosulfate, 2.5g of sodium sulfate, 2.5mL of phosphoric acid (mass concentration of 85%), 7.5 sulfur (fineness of 20 mesh) into the mill for full mixing for 0.5 hours. The mixed and milled materials are mechanically shaped, and then dried at 150°C so that th...

Embodiment 3

[0041] Weigh 7.5gLa(NO 3 ) 3 ﹒ 6H 2 O, 7.5gCe(NO 3 ) 3 ﹒ 6H 2 O, 7.5gNd(NO 3 ) 3 ﹒ 6H 2 O, 7.5gPr(NO 3 ) 3 ﹒ 6H 2 O was added to 400mL of distilled water, 150g of refined diatomaceous earth was added after complete dissolution, stirred for 30min, vacuum steamed at 60℃ for 12h, roasted at 400℃ for 4h to obtain material b; 2 O 5 , 10g KOH is fully dissolved in the same reaction tank, after mixing evenly, 2.5g organic polymer compound (polystyrene GH-660) and 2.5g surfactant (sodium dodecylbenzene sulfonate) are added to fully react to obtain KVO 3 Or NaVO 3 Solution, take 200mL, add 60mL dilute sulfuric acid (mass concentration 25%), react to form a uniform solution, add it to material b, and add 10gCs 2 SO 4 , 2.5g of thiosulfate, 2.5g of sodium sulfate, 2.5mL of phosphoric acid (mass concentration of 85%), 7.5 sulfur (fineness of 20 mesh) into the mill for full mixing for 0.5 hours. The mixed and milled materials are mechanically shaped, and then dried at 150°C so that the moi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com