Gold nanoring stacked array substrate with surface enhanced Raman scattering and preparation method

A technology of surface-enhanced Raman and array substrates, which is applied in Raman scattering, pattern surface photolithography, optomechanical equipment, etc. It can solve the requirements that cannot meet the requirements of large area, uniformity and high enhanced signal of SERS substrate at the same time , Difficult to control particle spacing and other issues, to achieve the effect of easy large-scale preparation, strong Raman signal enhancement effect, and easy control of period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

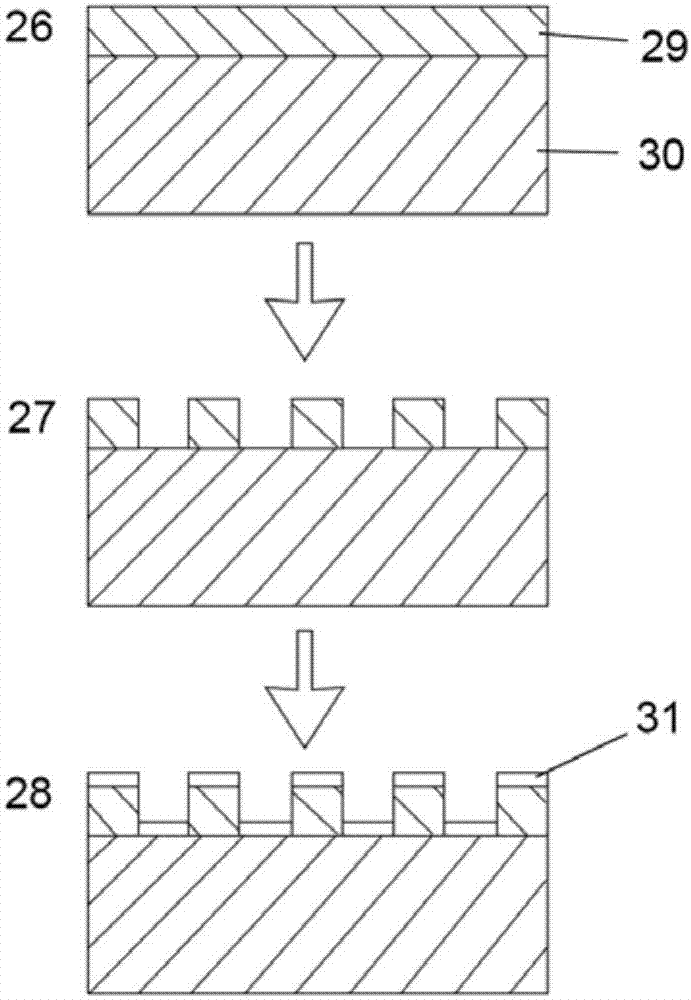

[0041] (1) cleaning the substrate, with a thickness of 1.2 mm single-sided polished silicon as the substrate material 30, its reflectivity in the visible light range is higher than 80%, it is placed in acetone, absolute ethanol, deionized water for ultrasonic cleaning, Blow dry with high-purity nitrogen for 100-150s each time, select positive photoresist 29, the type is AR-P3740 for glue coating, the resolution is 0.5μm, the rotation speed of the homogenizer is 4000r / min, and the thickness of the glue is 1.5μm, then put it on a hot plate, pre-baked at 100°C, the pre-baked time is 1min, take it off, and place it in dark conditions, such as image 3 The gluing process in is shown in 26;

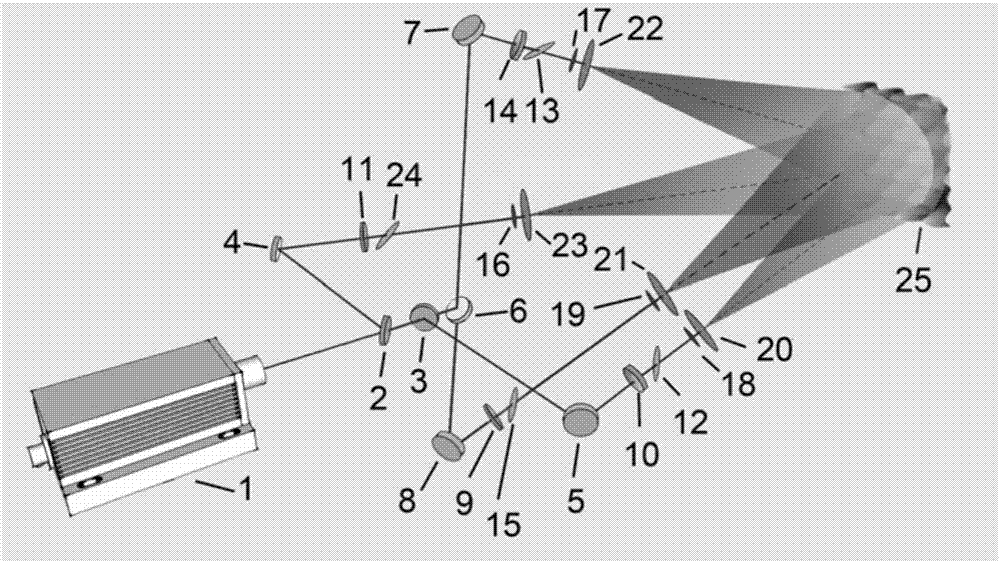

[0042] (2) Exposure is performed using a four-beam laser interference lithography system. The four-beam interference system generates modulation by controlling the incident angle. A 360nm semiconductor laser is the light source for the system, such as figure 2 As shown, the beam emitted by th...

Embodiment 2

[0047] (1) cleaning the substrate, with a thickness of 1.2 mm single-sided polished silicon as the substrate material 30, its reflectivity in the visible light range is higher than 80%, it is placed in acetone, absolute ethanol, deionized water for ultrasonic cleaning, Blow dry with high-purity nitrogen for 100-150s each time, select positive photoresist 29, the type is AR-P3740 for glue coating, the resolution is 0.5μm, the rotation speed of the homogenizer is 4000r / min, and the thickness of the glue is 1.5μm, then put it on a hot plate, pre-baked at 100°C, the pre-baked time is 1min, take it off, and place it in dark conditions, such as image 3 The gluing process in is shown in 26;

[0048] (2) Use a non-modulating three-beam interference lithography system for exposure. The incident angles of the first beam and the second beam of coherent light in the three beams are both 14°. At the same time, the spatial angles of the first beam of coherent light are respectively is 0°,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com