A Design Scheme of Cell Preparation Laboratory

A laboratory and cell technology, applied in the direction of small buildings, etc., can solve the problems of inability to meet the micro-cell experiment workflow and environmental requirements, and disorderly layout, etc., and achieve the effects of small footprint, clear sewage flow, and reasonable logistics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

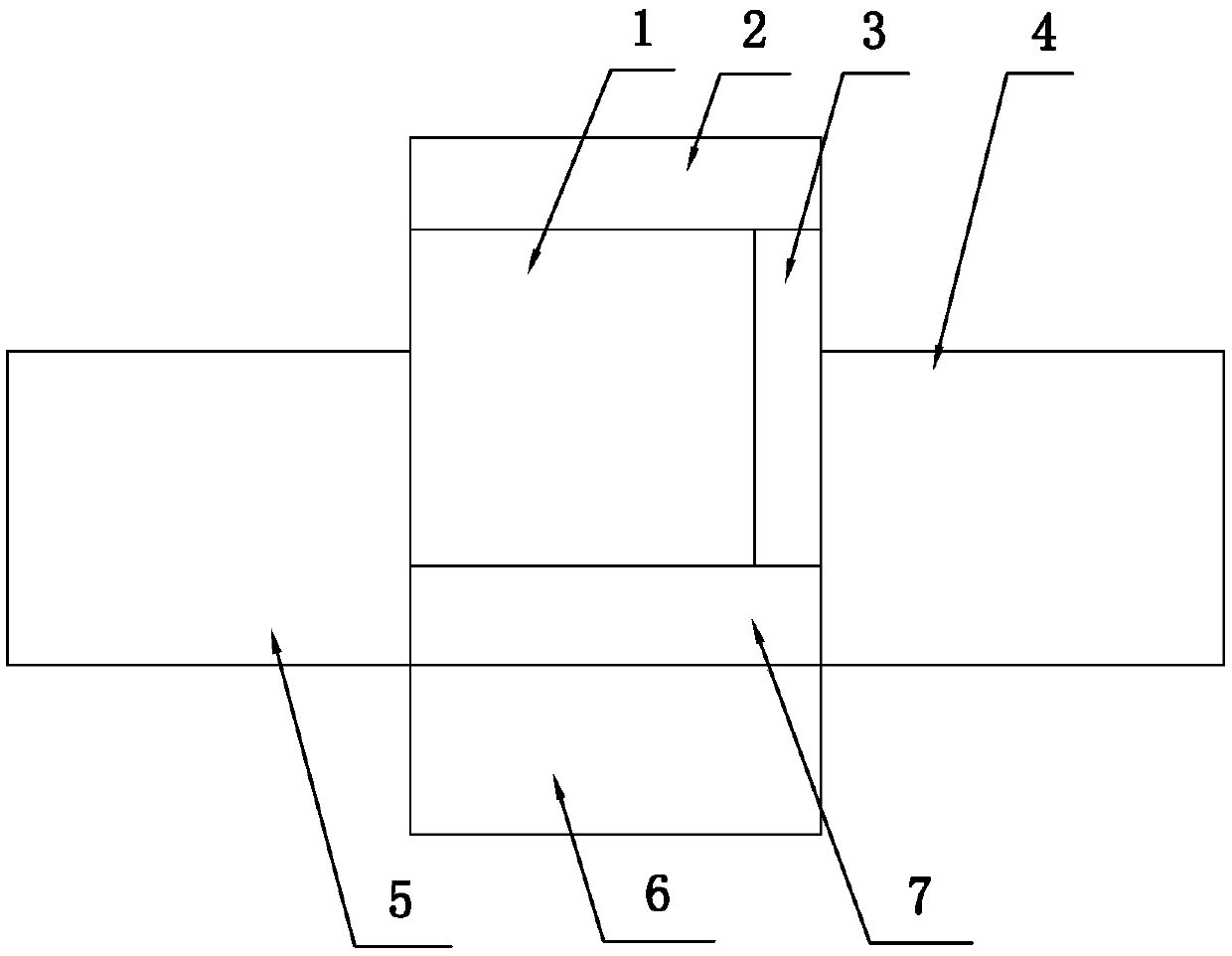

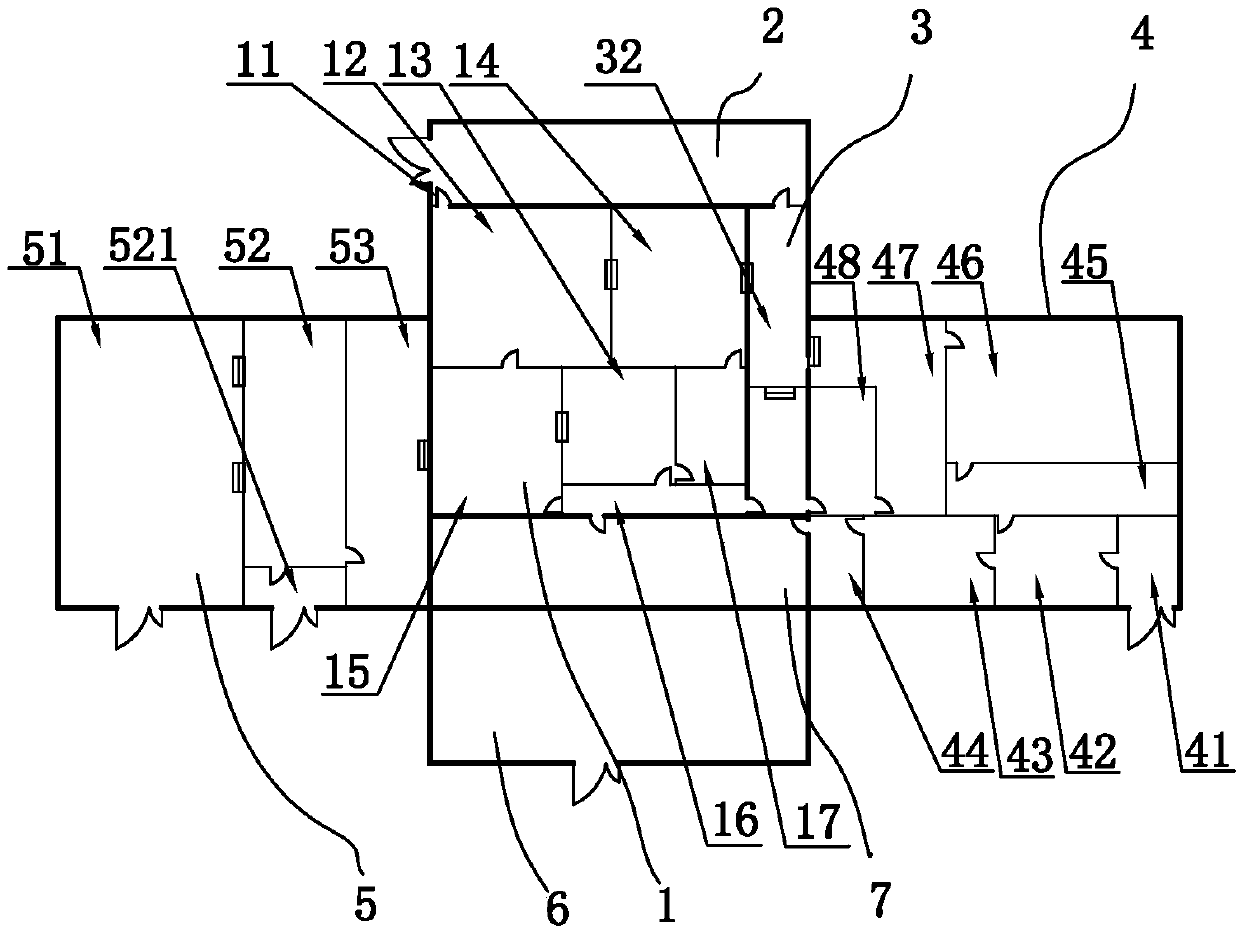

[0021] see figure 1 As shown, the present invention provides a design scheme of a cell preparation laboratory, including a preparation room 1, a logistics room 5, a treatment room 2, a human flow room 4 and a monitoring room 6 are sequentially arranged around the preparation room 1; the monitoring room A first preparation area 7 is provided between 6 and the preparation room 1; a second preparation area 3 is provided between the human flow chamber 4 and the preparation room 1; please refer to figure 2 As shown, the side adjacent to the processing chamber 2 inside the preparation chamber 1 is provided with an adjacent culture chamber 12 and a culture medium preparation room 14, the culture chamber 12 is adjacent to the logistics chamber 5, and the The culture medium preparation room 14 is adjacent to the second preparation area 3; an aseptic operation room 15 and a fourth buffer room 16 are arranged on the side adjacent to the first preparation area 7 inside the preparation ro...

Embodiment 2

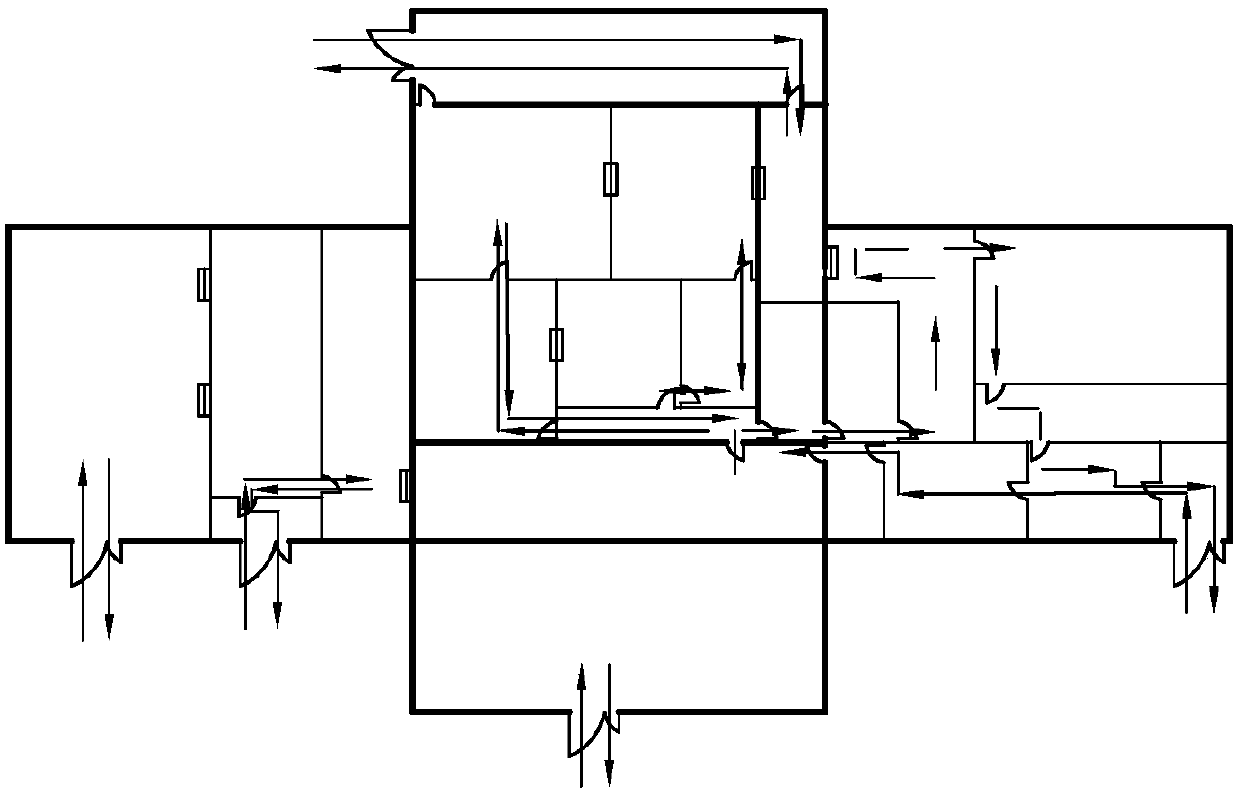

[0025] see figure 2 and image 3 As shown, as a technical optimization solution of the present invention, the inside of the flow room 4 is sequentially provided with a first buffer room 41 leading to the first preparation area 7, a changing room 42, an ultraviolet sterilizing room 43 and a first Airlock chamber 44; The inside of described human flow chamber 4 is also provided with the second buffer room 45 leading to the second preparation area 3, the flushing room 47 and the second airlock chamber 48 in sequence; The second buffer room 45 and The first buffer room 41, the dressing room 42 are adjacent to the ultraviolet sterilizing room 43, the other side of the second buffer room 45 is provided with a drying room 46, and the washing room 47 is connected to the second buffer room 45 and the drying room. The dry room 46 is adjacent, the second airlock chamber 48 is adjacent to the first airlock chamber 44 and the second preparation area 3 , and the connected rooms are provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com