Automatic continuous production device for nanocapsules and method for preparing nanocapsules

A technology of nanocapsules and production equipment, which is applied in the direction of microcapsule preparations, chemical instruments and methods, and microsphere preparation, and can solve problems such as difficulty in realizing large-scale production and manufacturing of nanocapsules, complicated operation of preparation devices, and high energy consumption, and achieve High shearing and emulsifying efficiency, compact equipment structure, and good particle dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0114] The preparation of embodiment 1 nanocapsule 1

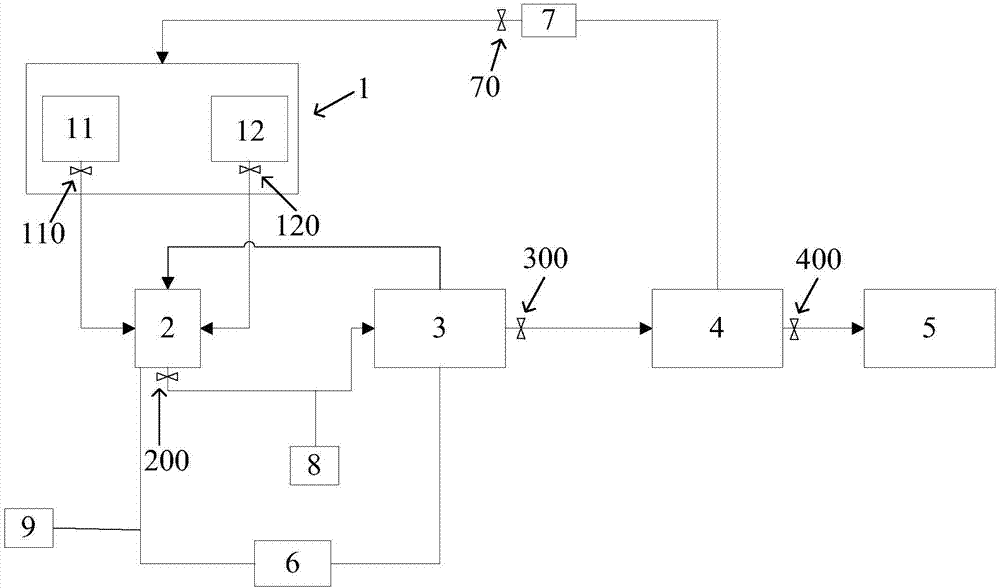

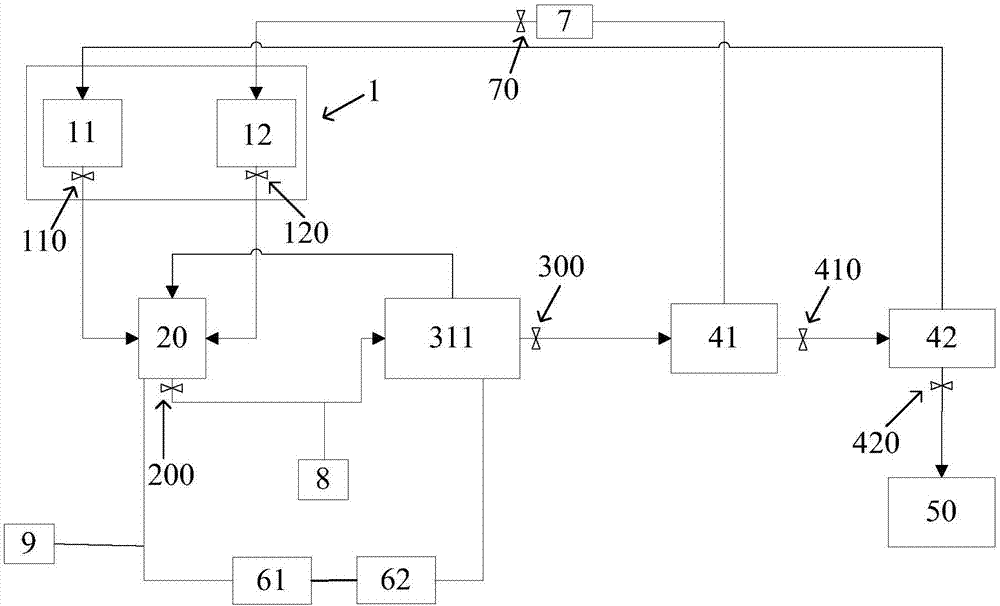

[0115] Such as figure 2 As shown, the nanocapsule automatic continuous production equipment in this embodiment includes a storage tank 1, a high-speed shear disperser 20, a high-shear three-stage emulsifier 311, a solvent recovery machine 41, and a centrifuge 42 connected in series through pipelines. And the filling machine 50, wherein the storage tank 1 includes a continuous phase storage tank 11 and a dispersed phase storage tank 12. The outlets of the continuous phase storage tank 11 and the dispersed phase storage tank 12 are respectively provided with valves 110, 120 to control the feeding sequence and feed amount of the continuous phase material and the dispersed phase material. The high-speed shear disperser 20, high Valves 200 , 300 , 410 , and 420 are respectively provided at the outlets of the three-stage shearing emulsifier 311 , the solvent recovery machine 41 and the centrifuge 42 to control the flow of mate...

Embodiment 2

[0119] The preparation of embodiment 2 nanocapsule 2

[0120] Such as image 3 As shown, the nanocapsule automatic continuous production equipment in the present embodiment includes a storage tank 1, a high-speed shear disperser 20, a high-shear three-stage emulsifier 311, a fast membrane emulsifier 312, and a solvent recovery tank 1 connected in series through pipelines. Machine 41, centrifuge 42 and filling machine 50, wherein storage tank 1 includes continuous phase storage tank 11 and dispersed phase storage tank 12. The outlets of the continuous phase storage tank 11 and the dispersed phase storage tank 12 are respectively provided with valves 110, 120 to control the feeding sequence and feed amount of the continuous phase material and the dispersed phase material. The high-speed shear disperser 20, high Valves 200, 301, 302, 410, 420 are respectively set at the outlets of the three-stage shearing emulsifier 311, fast membrane emulsifier 312, solvent recovery machine 41 ...

Embodiment 3

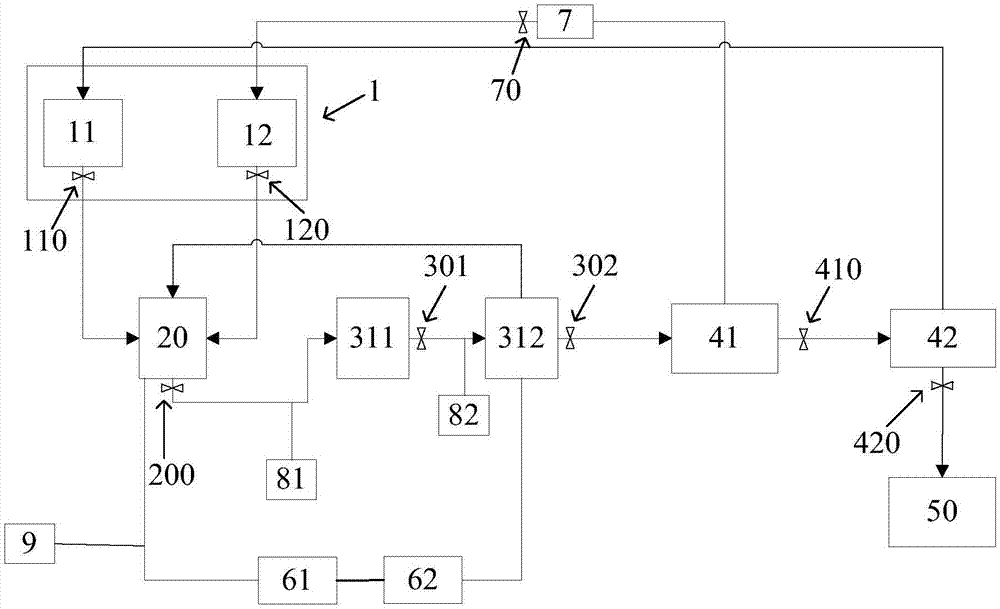

[0124] The preparation of embodiment 3 nanocapsule 3

[0125] Such as Figure 4As shown, the nanocapsule automatic continuous production equipment in the present embodiment includes a storage tank 1, a high-speed shear disperser 20, a high-shear three-stage emulsifier 311, a high-pressure homogenizer 321, and a solvent recovery tank 1 connected in series through pipelines. Machine 41, centrifuge 42 and filling machine 50, wherein storage tank 1 includes continuous phase storage tank 11 and dispersed phase storage tank 12. The outlets of the continuous phase storage tank 11 and the dispersed phase storage tank 12 are respectively provided with valves 110, 120 to control the feeding sequence and feed amount of the continuous phase material and the dispersed phase material. The high-speed shear disperser 20, high Valves 200, 301, 303, 410, 420 are respectively set at the outlets of the three-stage shearing emulsifier 311, high-pressure homogenizer 321, solvent recovery machine 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com