High-entropy alloy surface carburizing modification method

A technology of high-entropy alloy and surface carburizing, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc. Diffusion rate of elements and other issues to achieve the effect of increasing surface hardness, improving high temperature oxidation resistance, and good bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

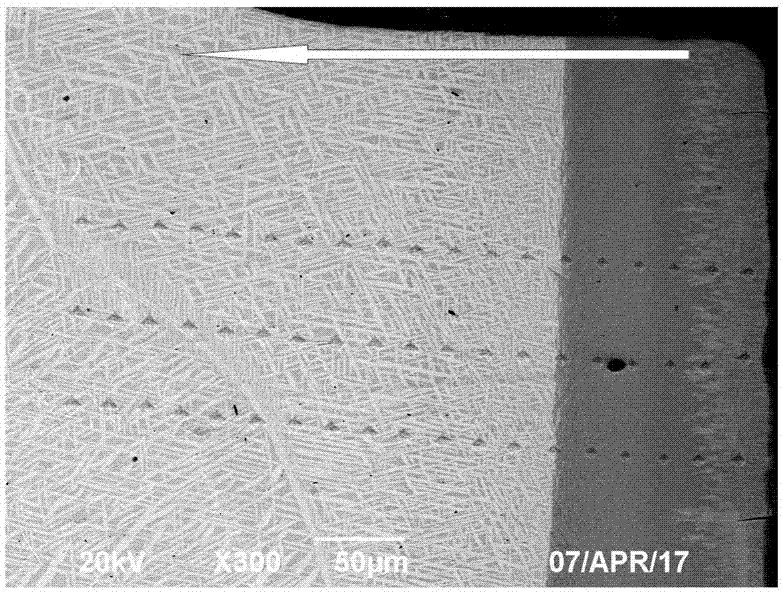

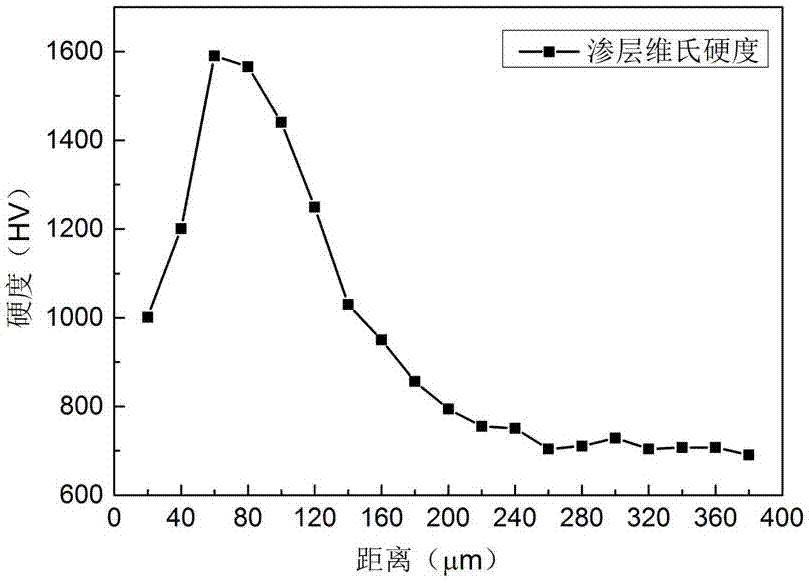

[0034] A method for carburizing and modifying the surface of a high-entropy alloy according to the present invention. The composition of the high-entropy alloy is HfZrTiTa, and the atomic molar ratio of each component Hf, Zr, Ti, and Ta is 1:1:1:1. When preparing the high-entropy alloy, the purity of the selected raw materials of Hf, Zr, Ti and Ta is not less than 99%, preferably 99%-99.99%. The selected carburizing agent is activated carbon powder of analytical purity and above.

[0035] A method for surface carburizing modification of a high-entropy alloy of the present invention, comprising the steps of:

[0036](1) Pretreatment of the HfZrTiTa high-entropy alloy raw material: the sample was cut into a rod-shaped sample of 1×1×15 mm by wire cutting, and the surface of the rod-shaped sample was polished with sandpaper until the metallic luster was exposed and the surface was smooth. The rod-shaped samples after grinding were ultrasonically cleaned with alcohol, and then dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com