Catalyst, preparation method thereof, composition prepared from catalyst and applications of catalyst and compositions

A catalyst and reaction technology, applied in the field of olefin catalysis, can solve the problem of low catalytic activity and achieve high activity, good catalytic performance, and easy to leave

- Summary

- Abstract

- Description

- Claims

- Application Information

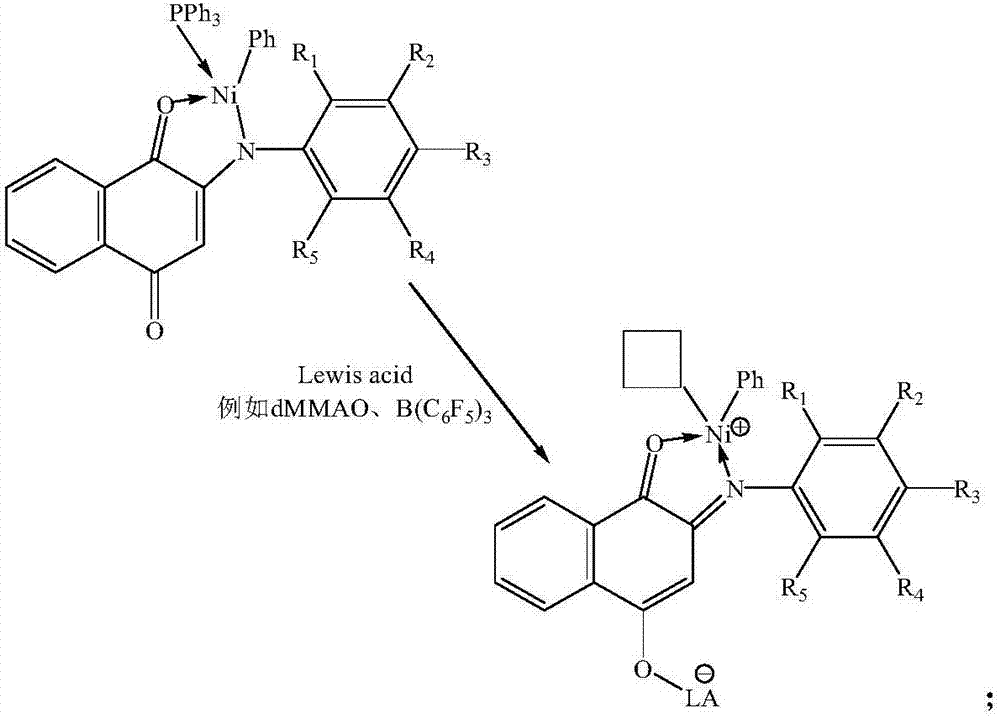

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

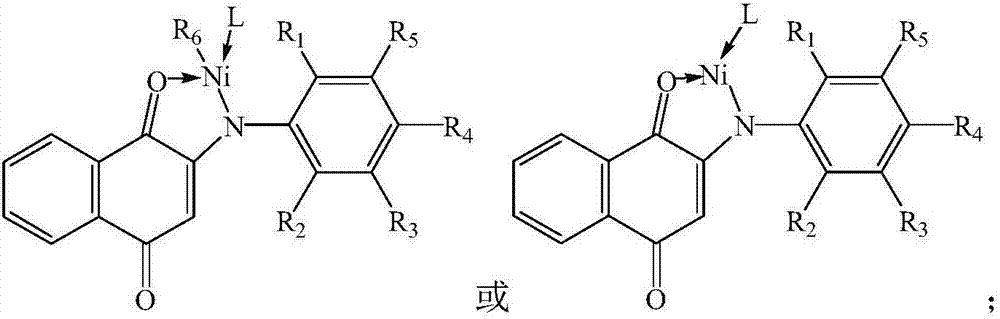

[0064] A preparation method of catalyst, the steps are as follows:

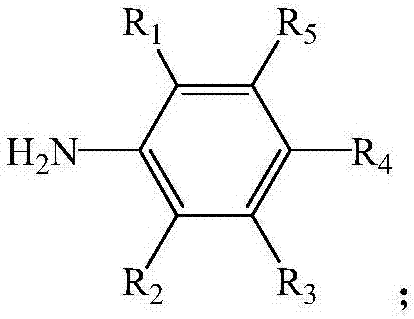

[0065] (1) Dissolve 2-hydroxy-1,4-naphthoquinone and substituted aniline in n-heptane, add trifluoroacetic acid to react to obtain anilinonaphthoquinone ligands, the reaction temperature is 100°C, the time is 15h, the reaction Initially, the molar ratio of 2-hydroxy-1,4-naphthoquinone to substituted aniline was 1:1.15, and the molar ratio of trifluoroacetic acid to 2-hydroxy-1,4-naphthoquinone was 0.33:1,2-hydroxy- The concentration of 1,4-naphthoquinone in n-heptane is 0.125mol / L, and the structural formula of substituted aniline is as follows:

[0066]

[0067] In the formula, R 1 is methyl, R 2 is ethyl, R 3 is methyl, R 4 is ethyl, R 5 It is a methyl group, and after the reaction, the anilinaquinone ligands are purified by toluene recrystallization;

[0068] (2) Dissolving the anilino-naphthoquinone ligands in toluene, adding sodium hydride to react to obtain a ligand salt compound, the temperatu...

Embodiment 2

[0074] A preparation method of catalyst, the steps are as follows:

[0075] (1) Dissolve 2-hydroxy-1,4-naphthoquinone and substituted aniline in toluene, add trifluoroacetic acid to react to obtain aniline naphthoquinone ligands, the reaction temperature is 110°C, the time is 6h, when the reaction starts , the molar ratio of 2-hydroxyl-1,4-naphthoquinone to substituted aniline is 1:1, the molar ratio of trifluoroacetic acid to 2-hydroxyl-1,4-naphthoquinone is 0.32:1, 2-hydroxyl-1, The concentration of 4-naphthoquinone in toluene is 0.1mol / L, and the structural formula of substituted aniline is as shown in embodiment 1, and in the formula, R 1 is ethyl, R 2 is methyl, R 3 is ethyl, R 4 is methyl, R 5 After the reaction, the anilinaquinone ligands are purified by n-hexane extraction;

[0076] (2) Dissolving the anilinaquinone ligands in tetrahydrofuran, adding potassium hydride to react to obtain a ligand salt compound, the reaction temperature is 40°C, and the time is 1h. ...

Embodiment 3

[0080] A preparation method of catalyst, the steps are as follows:

[0081](1) Dissolve 2-hydroxy-1,4-naphthoquinone and substituted aniline in chlorobenzene, add trifluoroacetic acid to react to obtain anilino-naphthoquinone ligands, the reaction temperature is 130°C, the time is 6h, and the reaction starts , the molar ratio of 2-hydroxy-1,4-naphthoquinone to substituted aniline is 1:1.02, and the molar ratio of trifluoroacetic acid to 2-hydroxy-1,4-naphthoquinone is 0.32:1,2-hydroxy-1 , the concentration of 4-naphthoquinone in chlorobenzene is 0.11mol / L, and the structural formula of substituted aniline is as shown in embodiment 1, and in the formula, R 1 is isopropyl, R 2 is tert-butyl, R 3 is tert-butyl, R 4 is isopropyl, R 5 It is isopropyl, and after the reaction, the p-aniline ligands are purified by recrystallization from tetrahydrofuran;

[0082] (2) Aniline naphthoquinone ligands are dissolved in dichloromethane, and n-butyllithium is added to react to obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com