Surface coating of lead ingot cold granulator

A technology of cold granulator and surface coating, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the surface corrosion of lead ingot cold granulator, inability to protect lead ingot cold granulator, The surface of the cold granulator has problems such as poor corrosion resistance, which can improve the corrosion resistance, improve the easy agglomeration, and reduce the degree of polymerization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

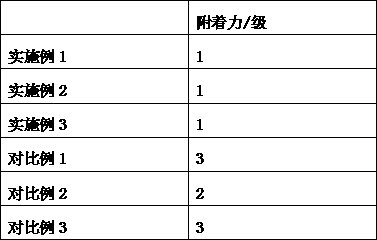

Examples

Embodiment 1

[0014] A surface coating of lead ingot cold granulator, which is made of the following components in parts by weight: waterborne polyurethane emulsion 80, coupling agent modified nano silica 3, benzene sulfonic acid 4, pentaerythritol 12, polyterephthalic alcohol 0.5. Molybdenum dialkyldithiocarbamate 1.2, acidified starch 20, sodium alginate modified attapulgite 5, water 60.

[0015] Further: the preparation method of the acidified starch is: preparing an organic acid solution with a mass fraction of 5%, treating the starch with a 350W microwave for 2 minutes, and then uniformly mixing the microwave-treated starch with the organic acid solution in a ratio of 200g:450mL Mix together, heat to 90°C, stir at 3000r / min for 40min, then stand to cool to room temperature, filter, wash the starch with deionized water until it is neutral, and then dry to constant weight to get.

[0016] Further: the organic acid is any one of oxalic acid, malonic acid, succinic acid and maleic acid.

[0017]...

Embodiment 2

[0022] A surface coating of lead ingot cold granulator, which is made of the following ingredients in parts by weight: waterborne polyurethane emulsion 90, coupling agent modified nano silica 5, benzene sulfonic acid 6, pentaerythritol 18, polyterephthalic alcohol 0.8, molybdenum dialkyldithiocarbamate 1.8, acidified starch 25, sodium alginate modified attapulgite 10, water 80.

[0023] Further: the preparation method of the acidified starch is: preparing an organic acid solution with a mass fraction of 5%, treating the starch with a 350W microwave for 2 minutes, and then uniformly mixing the microwave-treated starch with the organic acid solution in a ratio of 200g:450mL Mix together, heat to 90°C, stir at 3000r / min for 40min, then stand to cool to room temperature, filter, wash the starch with deionized water until it is neutral, and then dry to constant weight to get.

[0024] Further: the organic acid is any one of oxalic acid, malonic acid, succinic acid and maleic acid.

[002...

Embodiment 3

[0030] A surface coating for lead ingot cold granulator, which is made of the following components in parts by weight: waterborne polyurethane emulsion 85, coupling agent modified nano silica 4, benzene sulfonic acid 5, pentaerythritol 15, polyterephthalic alcohol 0.6, molybdenum dialkyldithiocarbamate 1.5, acidified starch 22, sodium alginate modified attapulgite 8, water 70.

[0031] Further: the preparation method of the acidified starch is: preparing an organic acid solution with a mass fraction of 5%, treating the starch with a 350W microwave for 2 minutes, and then uniformly mixing the microwave-treated starch with the organic acid solution in a ratio of 200g:450mL Mix together, heat to 90°C, stir at 3000r / min for 40min, then stand to cool to room temperature, filter, wash the starch with deionized water until it is neutral, and then dry to constant weight to get.

[0032] Further: the organic acid is any one of oxalic acid, malonic acid, succinic acid and maleic acid.

[0033...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com