Modified polymer material and preparation method thereof

A polymer material and modification technology, which is applied in the field of modified polymer materials and its preparation, can solve the problem that polyborosiloxane is difficult to give full play to its advantages, easily sacrifices the processing performance of polymer materials, and cannot fully exert the modification effect and other problems, to achieve the effect of outstanding thermal stability, excellent storage stability, and easy molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

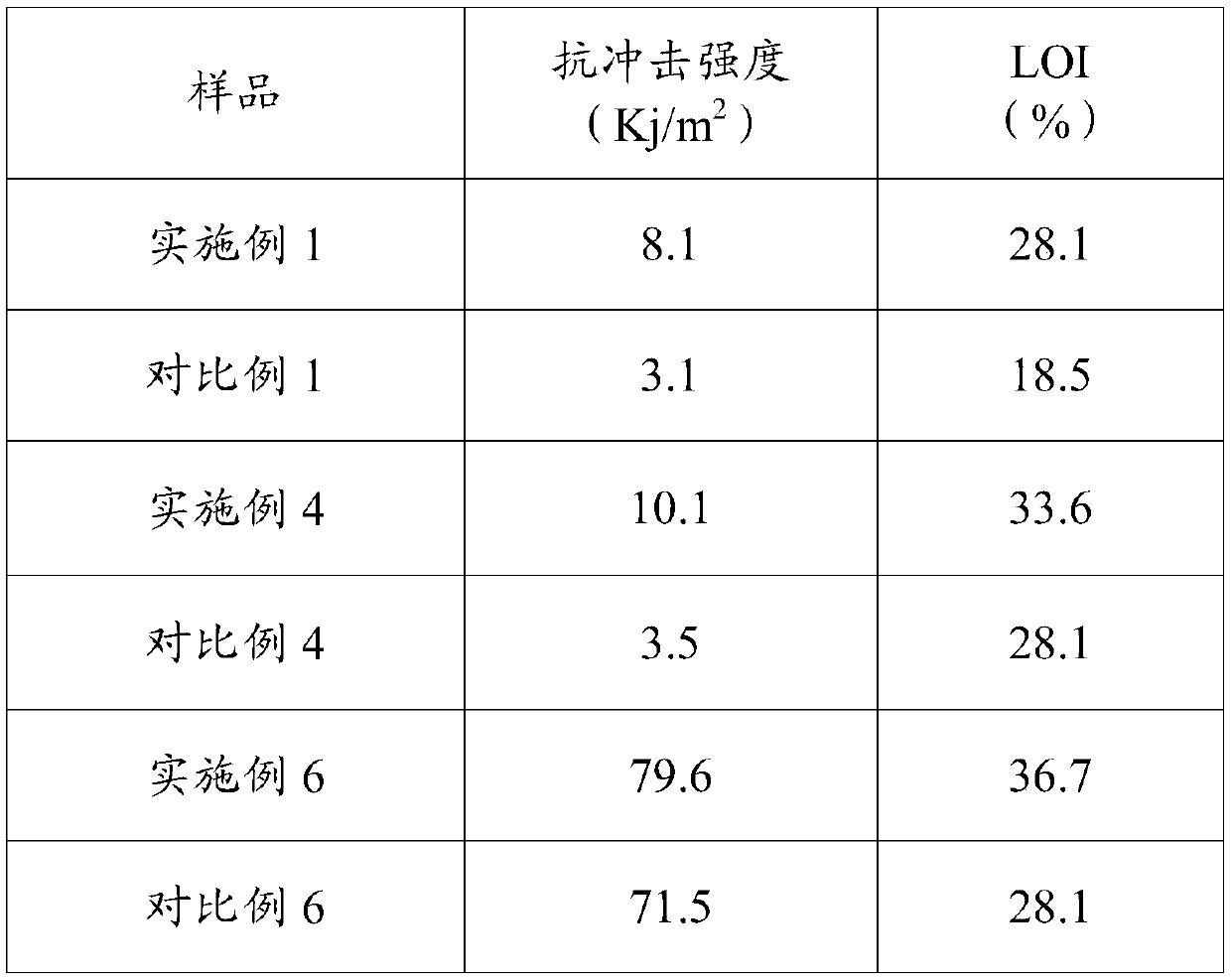

Examples

Embodiment 1

[0034] 1) Under the conditions of stirring and nitrogen protection, first add 23.61g of γ-glycidoxypropyltrimethoxysilane, 5.60g of boric acid, 5.15g of deionized water and 0.09g of 20% tetramethylammonium hydroxide solution into three ports After the flask, reflux at a constant temperature of 30°C for 2 hours to obtain solution A;

[0035] 2) Under the conditions of stirring and nitrogen protection, add 30.89g of trimethylchlorosilane, 18.00mL of methanol and 36.00mL of pyridine into the solution A obtained in step 1), and reflux at 40°C for 6 hours, Obtain crude product after vacuum distillation;

[0036] 3) Then after the crude product is dissolved in 1g of dichloromethane, the insoluble matter is filtered off, and after vacuum distillation and vacuum drying, hyperbranched polyborosiloxane is obtained, and its molecular formula is:

[0037] [(CH 3 ) 3 SiO 1 / 2 ] a [R 1 R 2 2 SiO 1 / 2 ] b [R 1 R 2 SiO 2 / 2 ] c [R 1 SiO 3 / 2 ] d

[0038] [R 3 2 BO 1 / 2 ] e [R...

Embodiment 2

[0044] 1) Under stirring conditions, first add 23.61g of γ-glycidoxypropyltrimethoxysilane, 9.41g of trimethyl borate, 3.43g of deionized water and 0.04g of KOH into a three-necked flask, and keep the temperature at 90°C Reflux for 30 hours to obtain solution A;

[0045] 2) Add 15.44g of hexamethyldisiloxane, 5.00mL of n-butanol and 8.30mL of tetrahydrofuran into the solution A obtained in step 1) under stirring conditions, and reflux at 90°C for 20 hours Afterwards, crude product is obtained after distillation under reduced pressure;

[0046] 3) After the crude product is dissolved in 1000g of dichloromethane, the insoluble matter is filtered off, and after vacuum distillation and vacuum drying, hyperbranched polyborosiloxane is obtained.

[0047] Its molecular formula is:

[0048] [(CH 3 ) 3 SiO 1 / 2 ] a [R 1 R 2 2 SiO 1 / 2 ] b [R 1 R 2 SiO 2 / 2 ] c [R 1 SiO 3 / 2 ] d

[0049] [R 3 2 BO 1 / 2 ] e [R 4 2 BO 1 / 2 ] f [R 3 R 4 BO 1 / 2 ] g [R 3 BO 2 / 2 ] ...

Embodiment 3

[0053] 1) Under stirring and nitrogen protection conditions, first add 23.80g 3-mercaptopropyltriethoxysilane, 13.00g triethyl borate, 4.46g deionized water and 0.05g p-toluenesulfonic acid into a three-necked flask, and then Reflux at constant temperature for 4 hours at 65°C to obtain solution A;

[0054] 2) Under the conditions of stirring and nitrogen protection, then add a mixed solvent consisting of 23.22g of hexamethyldisiloxane, 20.00mL of ethanol and 10.00mL of pyridine into the solution A obtained in step 1), and reflux at 65°C for 7 After one hour, the crude product was obtained after distillation under reduced pressure;

[0055] 3) Then after the crude product is dissolved in 50g toluene, the insoluble matter is filtered off, and after vacuum distillation and vacuum drying, hyperbranched polyborosiloxane is obtained, and its molecular formula is:

[0056] [(CH 3 ) 3 SiO 1 / 2 ] a [R 1 R 2 2 SiO 1 / 2 ] b [R 1 R 2 SiO 2 / 2 ] c [R 1 SiO 3 / 2 ] d

[0057] [...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com