Modified eggshell membrane paper for lithium battery recovery, and preparation method and application thereof

A lithium battery and egg membrane technology, applied in the field of modified egg membrane paper and preparation, can solve the problems of unadjustable targeted screening of soluble ions, strong alkali and strong acid pollution, etc., and achieves significant market application value, easy continuous production, and improved Effect of Ion Separation Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

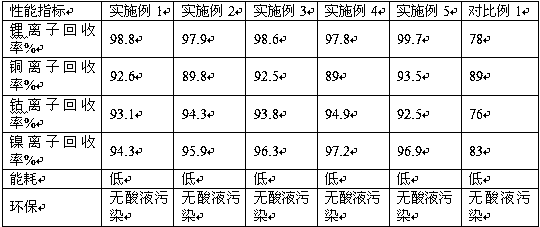

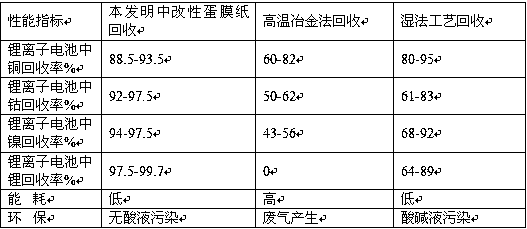

Examples

Embodiment 1

[0036] (1) According to the weight ratio of egg membrane powder to weak alkaline solution of 1:3, add egg membrane powder to ammonia solution with pH=9, stir evenly at 60rpm, modify the surface for 20 minutes, activate membrane protein Surface -OH, -COOH, -NH 2 The functional group is then used to split the disulfide bond on the surface of the egg membrane with thioglycolic acid to form a sulfhydryl group to obtain a surface-modified egg membrane powder, and the weight ratio of the thioglycolic acid to the egg membrane powder is 0.5:1;

[0037] (2) Mix 1 part of the surface-modified egg film powder obtained in step (1) with 1 part of wollastonite fiber according to mass parts, and add 0.01 parts of surfactant sodium perfluorooctanoate and 0.01 parts of GPE type according to mass parts Antifoaming agent, 0.01 part thickening agent gum arabic, stir evenly at a speed of 60 rpm to obtain egg film paper precursor;

[0038] (3) The egg film precursor of step (2) is rolled by a roller at ...

Embodiment 2

[0042] (1) According to the weight ratio of egg membrane powder to weak alkaline solution of 1:4, add egg membrane powder to the weak alkaline solution of ammonia water with pH=9.3, stir evenly at 90rpm, and modify the surface. Minutes to activate -OH, -COOH, -NH on the surface of membrane protein 2 The functional group is then used to split the disulfide bond on the surface of the egg membrane with thioglycolic acid to form a sulfhydryl group to obtain a surface-modified egg membrane powder. The weight ratio of the thioglycolic acid to the egg membrane powder is 0.8:1;

[0043] (2) Mix 1 part of the surface-modified egg film powder obtained in step (1) with 2 parts of flax fiber according to mass parts, and add 0.03 parts of surfactant sodium perfluorooctyl sulfonate, 0.04 parts by mass One part GPE type defoamer and 0.09 part thickening agent carrageenan were stirred evenly at a speed of 130 rpm to obtain egg film paper precursor;

[0044] (3) The egg film precursor of step (2) i...

Embodiment 3

[0048] (1) According to the weight ratio of egg film powder to weak alkaline solution of 1:5, add egg film powder to the weak alkaline solution of potassium hydroxide with pH=9.5, stir evenly at 180rpm to modify the surface 30 minutes, activate -OH, -COOH, -NH on the surface of membrane protein 2 The functional group is then used to split the disulfide bond on the surface of the egg membrane with thioglycolic acid to form a sulfhydryl group to obtain a surface-modified egg membrane powder, and the weight ratio of the thioglycolic acid to the egg membrane powder is 1.3:1;

[0049] (2) Mix 1 part of the surface-modified egg film powder obtained in step (1) with 2 parts of hemp fiber according to mass parts, and add 0.04 parts of surfactant sodium perfluorooctanoate and 0.08 parts of GP type defoamer according to mass parts 0.11 part of thickener pectin, stir evenly at a speed of 150rpm to obtain egg film paper precursor;

[0050] (3) The egg film precursor of step (2) is rolled by a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com