Novel ampicillin sodium used for injection

A technology for ampicillin sodium and injection, which is used in injections and its preparation. The new field of ampicillin sodium for injection and its preparation can solve the problems of not being converted into commercial products, microcapsule technology stays, and a small number, etc., and achieve cost The effect of low, shortened medication interval, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1 Preparation of p-dioxanone-lactide copolymer according to the present invention

[0023] P-dioxanone and lactide are put into a three-necked flask according to the weight ratio, and catalyst stannous octoate (3.56% of the lactide monomer quality) and initiator lauryl alcohol (lactide) are added under the protection of nitrogen. 2.72% of the monomer mass), vacuumed to 10Pa, heated to 185°C under stirring, reacted for 1.5h, stopped stirring, kept vacuum for 4h, and then naturally cooled to room temperature. Dissolve the product with a small amount of dichloromethane, then settle with petroleum ether 3 times the volume of the solution, and filter with suction, repeating this process 3 times, and finally the obtained copolymer product is dried under reduced pressure at 40°C for 3 hours in a vacuum drying oven to obtain different proportions The finished product of dioxanone-lactide copolymer.

Embodiment 2

[0024] Example 2 Preparation of Ampicillin Sodium for Injection according to the present invention, specification: 1.0g

[0025] prescription:

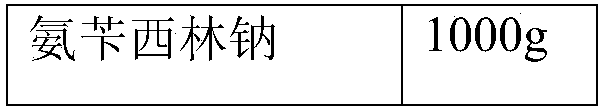

[0026] Ampicillin Sodium

1000g

6000g

Sodium carboxymethyl cellulose

3500g

1800g

1000g

p-dioxanone-lactide copolymer (29.3:70.7)

1200g

talcum powder

800g

Polyethylene glycol-4000

35000g

[0027] The specific steps are:

[0028] Weigh xanthan gum and sodium carboxymethylcellulose, stir and dissolve in water at about 30°C, add ampicillin sodium and emulsifier, and stir with a homogenizer to obtain an emulsion; then add anti-sticking agent talcum powder and stabilizer to the emulsion Dioxanone-lactide copolymer (29.3:70.7), stir to disperse evenly, and spray dry to obtain white powdery microcapsules; mix the microcapsules with the prepared solvent polyethylene glycol- 4000, mix well, dispense, fill with nitrogen and ...

Embodiment 3

[0030] Example 3 Preparation of Ampicillin Sodium for Injection according to the present invention, specification: 0.5g

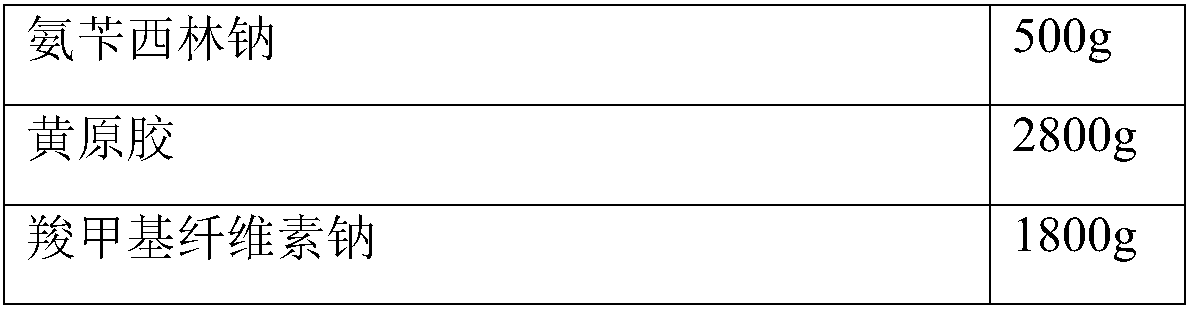

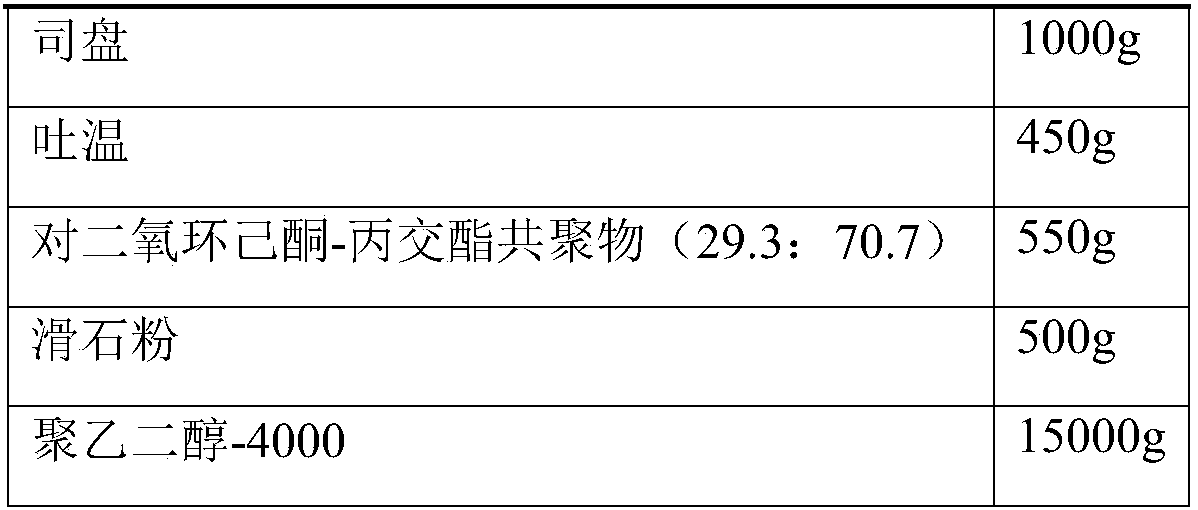

[0031] prescription:

[0032]

[0033]

[0034] The specific steps are:

[0035] Weigh xanthan gum and sodium carboxymethylcellulose, stir and dissolve in water at about 30°C, add ampicillin sodium and emulsifier, and stir with a homogenizer to obtain an emulsion; then add anti-sticking agent talcum powder and stabilizer to the emulsion Dioxanone-lactide copolymer (29.3:70.7), stir to disperse evenly, and spray dry to obtain white powdery microcapsules; mix the microcapsules with the prepared solvent polyethylene glycol- 4000, mix well, dispense, fill with nitrogen and seal for sterilization.

[0036] The spray drying conditions are as follows: inlet temperature 160° C., feed rate 6.6 ml / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com