Method for strengthening tensile performance of aluminum-silicon alloy through FeBSi metal glass

A technology of metallic glass and tensile properties, which is applied in the field of aluminum alloy processing, can solve the problems of insignificant structure refinement of Al-Si alloys, failure of aluminum alloys to meet industrial needs, and extremely high purity requirements of aluminum alloys. Application potential and value, significant strengthening effect, and low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

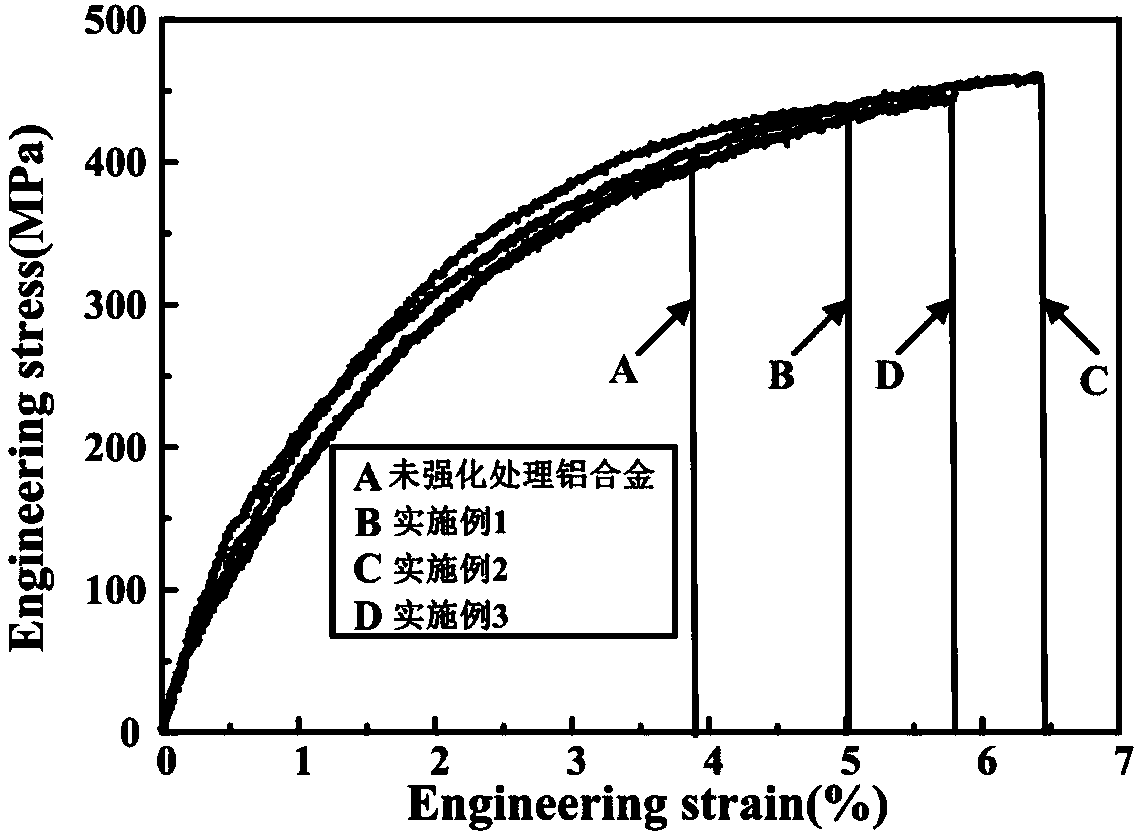

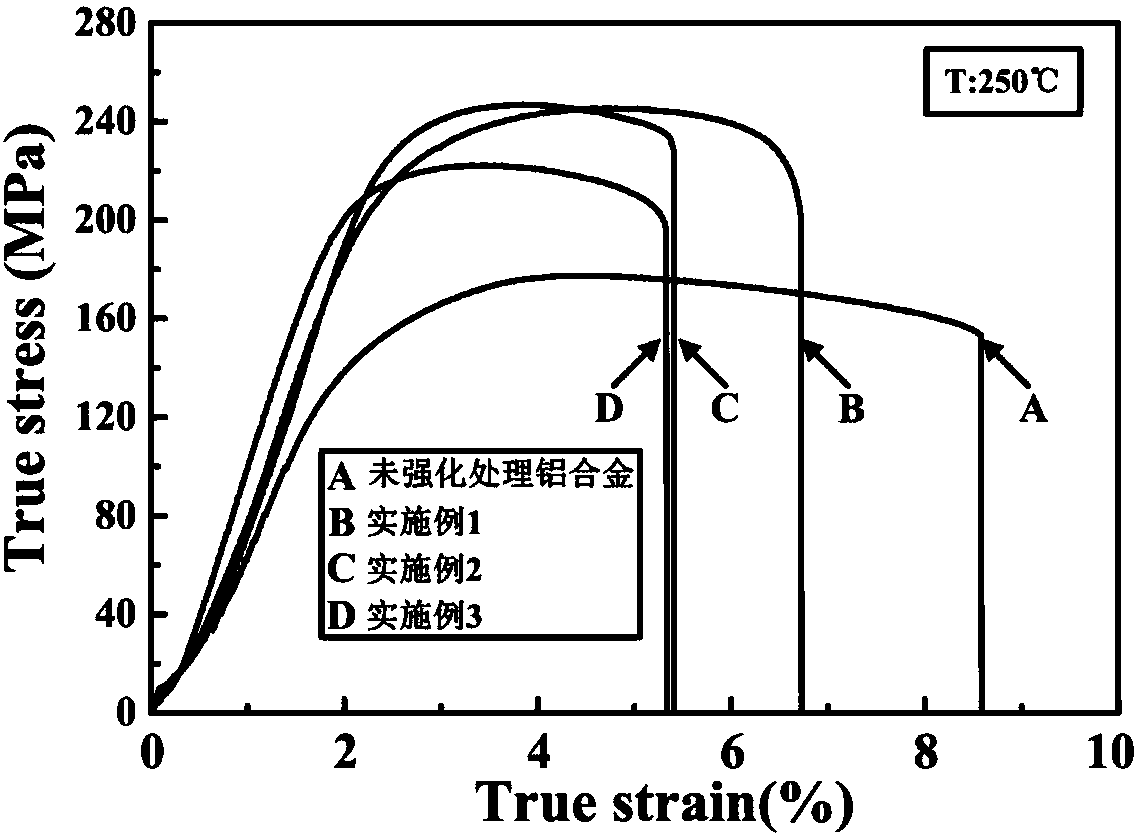

Embodiment 1

[0039] The method of utilizing FeBSi metallic glass in this embodiment to strengthen the tensile properties of Al-Si alloy comprises the following steps:

[0040] Step 1, preparation of metal-containing glass strengthening agent:

[0041] 1a. Place 30g of FeBSi metallic glass strips in an aging furnace for annealing at a temperature of 473K for 2h.

[0042] 1b. Add 30g of FeBSi metallic glass strips after annealing treatment into a steel tank containing ZrO with diameters of 5mm, 7mm, 11mm, 15mm, 20mm and 22mm respectively. 2 Balls, 10 of each, ZrO 2The mass of the ball is 800g in total, and the metallic glass strip is ball-milled for 0.5h at a rotational speed of 200r / min to obtain FeBSi metallic glass powder.

[0043] 1c. Mix the metallic glass powder after ball milling with aluminum powder (the purity of aluminum powder is 99.9wt.% Al) at a mass ratio of 3:7 and put it into a steel tank again, and mix it uniformly at a speed of 50r / min for 8 hours take out.

[0044] 1d....

Embodiment 2

[0063] The method of utilizing FeBSi metallic glass in this embodiment to strengthen the tensile properties of Al-Si alloy comprises the following steps:

[0064] Step 1, preparation of metal-containing glass strengthening agent:

[0065] 1a. Place 30g of FeBSi metallic glass strips in an aging furnace for annealing treatment at a temperature of 523K for 4h.

[0066] 1b. Add 30g of FeBSi metallic glass strips after annealing treatment into a steel tank containing ZrO with diameters of 5mm, 7mm, 11mm, 15mm, 20mm and 22mm respectively. 2 Balls, 10 of each, ZrO 2 The mass of the ball is 800g in total, and the metallic glass strip is ball-milled for 2h at a rotational speed of 300r / min to obtain FeBSi metallic glass powder.

[0067] 1c. The metallic glass powder after ball milling is mixed with aluminum powder (aluminum powder purity 99.9wt.% Al) in a mass ratio of 3:7, and then put into a steel tank again, and mixed uniformly at a speed of 50r / min for 10h take out.

[0068] 1...

Embodiment 3

[0087] The method of utilizing FeBSi metallic glass in this embodiment to strengthen the tensile properties of Al-Si alloy comprises the following steps:

[0088] Step 1, preparation of metal-containing glass strengthening agent:

[0089] 1a. Place 30g of FeBSi metallic glass strips in an aging furnace for annealing treatment at a temperature of 523K for 4h.

[0090] 1b. Add 30g of FeBSi metallic glass strips after annealing treatment into a steel tank containing ZrO with diameters of 5mm, 7mm, 11mm, 15mm, 20mm and 22mm respectively. 2 Balls, 10 of each, ZrO 2 The mass of the ball is 800g in total, and the metallic glass strip is ball-milled for 2h at a rotational speed of 200r / min to obtain FeBSi metallic glass powder.

[0091] 1c. The metallic glass powder after ball milling is mixed with aluminum powder (aluminum powder purity 99.9wt.% Al) in a mass ratio of 3:7, and then put into a steel tank again, and mixed uniformly at a speed of 50r / min for 15h take out.

[0092] 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com