Preparation method of heat, oxygen and light-resistant antioxidant

A technology of anti-aging agent and anti-thermal oxygen, which is applied in the field of preparation of anti-thermal-oxygen light-type anti-aging agent, can solve the problems that natural rubber cannot be used, and natural rubber is easy to age, so as to prevent the autocatalytic process, improve the performance of vulcanizate, Anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

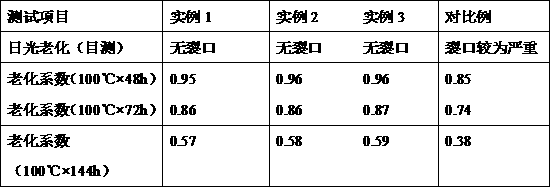

Examples

example 1

[0024]Weigh 20g sodium vitamin C and pour it into 45mL deionized water, mix and stir for 10min to obtain self-made solution 1, weigh 16g lanthanum chloride and pour it into 35mL absolute ethanol and mix and stir for 8min to obtain self-made solution 2, and add self-made solution 2 dropwise to Self-made solution 1, and reacted in a water bath at 28°C for 45 minutes to obtain a reaction solution, then added 6 mL of acetone to the reaction solution, and continued to keep warm for 10 minutes to obtain a self-made precipitate, which was poured into a suction filter for suction filtration. Remove the filter residue, wash the precipitate with absolute ethanol and acetone for 20 minutes, and finally put it in an oven at 60°C for 1 hour, cool it down to room temperature naturally, pass it through a 100-mesh sieve after grinding for 8 minutes, collect the sieved powder 1, and weigh 16g of oxidation Graphite was put into a mixture of 20mL deionized water and 10mL absolute ethanol, and ult...

example 2

[0026] Weigh 25g sodium vitamin C and pour it into 55mL deionized water, mix and stir for 11min to obtain self-made solution 1, weigh 18g lanthanum chloride and pour it into 45mL absolute ethanol and mix and stir for 9min to obtain self-made solution 2, and add self-made solution 2 dropwise to Self-made solution 1, and reacted in a water bath at 32°C for 53 minutes to obtain a reaction solution, then added 7 mL of acetone to the reaction solution, and continued to keep warm for 11 minutes to obtain a self-made precipitate, which was poured into a suction filter for suction filtration. Remove the filter residue, wash the precipitate with absolute ethanol and acetone for 25 minutes, and finally put it in an oven at 70°C for 1.5 hours, cool it down to room temperature naturally, grind it for 9 minutes, pass through a 100-mesh sieve, collect the sieved powder 1, and weigh 18g Graphite oxide was put into a mixture of 25mL deionized water and 11mL absolute ethanol, and ultrasonically...

example 3

[0028] Weigh 30g sodium vitamin C and pour it into 65mL deionized water and mix and stir for 12min to obtain self-made solution 1. Weigh 20g lanthanum chloride and pour it into 55mL absolute ethanol and mix and stir for 10min to obtain self-made solution 2. Add self-made solution 2 dropwise to Self-made solution 1, and reacted in a water bath at 36°C for 60 minutes to obtain a reaction solution, then added 8 mL of acetone to the reaction solution, and continued to keep warm for 12 minutes to obtain a self-made precipitate, which was poured into a suction filter for suction filtration. Remove the filter residue, wash the precipitate with absolute ethanol and acetone for 30 minutes, and finally put it in an oven at 80°C for 2 hours, cool it down to room temperature naturally, and pass it through a 100-mesh sieve after grinding for 10 minutes, collect the sieved powder 1, and weigh 20 g of Graphite was put into a mixed solution of 30mL deionized water and 12mL absolute ethanol, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com