Traditional Chinese medicine sustained-release tablet and preparation method thereof

A technology of sustained-release tablets and traditional Chinese medicine, which is applied in the fields of medical formula, drug combination, drug delivery, etc. It can solve the problems of slow curative effect, only single blood pressure reduction, and ineffective therapeutic effect, so as to achieve short treatment period, avoid toxic and side effects, and prolong the treatment period. The effect of effective action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

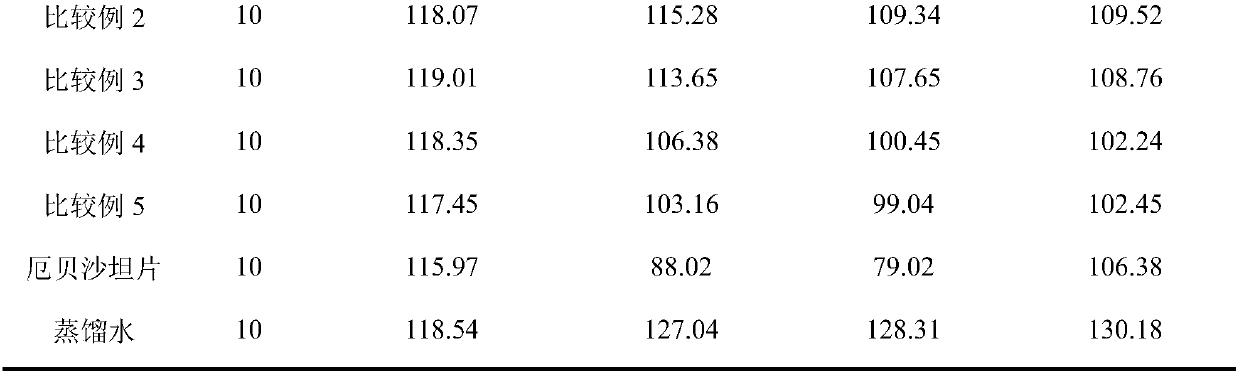

Embodiment 1

[0028] Weigh 25 parts of Eucommia ulmoides, 20 parts of Gastrodia elata, 18 parts of apocynum, 10 parts of green tea, 6 parts of cassia seed, 10 parts of Gynostemma pentaphyllum, 10 parts of Ganoderma lucidum, 5 parts of Orchid chinensis, 4 parts of Poria cocos, 3 parts of gardenia and seaweed by weight. Artemisia 3 parts, pulverize, mix, pass 100 mesh sieves to obtain coarse powder, carry out superfine pulverization to coarse powder, pass 500 mesh sieves again to obtain fine powder, then fine powder and volume fraction are 85% ethanol solution by mass Mixed at a ratio of 1:3, treated at 50°C with a frequency of 300MHz ultrasonic waves for 60 minutes, during ultrasonic treatment, every 3 minutes of ultrasonic treatment, paused for 1 minute, and then carried out suction filtration to obtain the first filtrate and the first filter residue; the first filtrate was reduced Pressure distillation, concentration to a relative density of 1.30, and then at 50°C and 25MPa, fluid extractio...

Embodiment 2

[0030]Weigh 22 parts of Eucommia ulmoides, 18 parts of Gastrodia elata, 20 parts of apocynum, 8 parts of green tea, 5 parts of cassia seed, 8 parts of Gynostemma pentaphyllum, 8 parts of ganoderma lucidum, 6 parts of tooth blue, 3 parts of poria cocos, 4 parts of gardenia and seaweed by weight. 4 parts of artemisia, pulverized, mixed, passed through a 100-mesh sieve to obtain a coarse powder, the coarse powder was ultrafinely pulverized, and then passed through a 500-mesh sieve to obtain a fine powder, and then the fine powder was mixed with an ethanol solution with a volume fraction of 85%. Mixed at a ratio of 1:3, treated at 50°C with a frequency of 300MHz ultrasonic waves for 60 minutes, during ultrasonic treatment, every 3 minutes of ultrasonic treatment, paused for 1 minute, and then carried out suction filtration to obtain the first filtrate and the first filter residue; the first filtrate was reduced pressure distillation, concentrated to a relative density of 1.28, and ...

Embodiment 3

[0032] Weigh 20 parts of Eucommia ulmoides, 22 parts of Gastrodia elata, 15 parts of apocynum, 9 parts of green tea, 8 parts of cassia seed, 9 parts of Gynostemma pentaphyllum, 9 parts of Ganoderma lucidum, 8 parts of Orchid chinensis, 5 parts of Poria cocos, 5 parts of gardenia and seaweed by weight. 5 parts of artemisia, pulverized, mixed, passed through a 100-mesh sieve to obtain a coarse powder, the coarse powder was ultrafinely pulverized, and then passed through a 500-mesh sieve to obtain a fine powder, and then the fine powder and an ethanol solution with a volume fraction of 85% were mixed by mass Mixed at a ratio of 1:3, treated at 50°C with a frequency of 300MHz ultrasonic waves for 60 minutes, during ultrasonic treatment, every 3 minutes of ultrasonic treatment, paused for 1 minute, and then carried out suction filtration to obtain the first filtrate and the first filter residue; the first filtrate was reduced pressure distillation, concentrated to a relative density...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com