Regulation and control method of flexible molybdenum substrate-based cadmium-doped copper zinc tin sulfur selenium thin film with band gap gradient

A copper-zinc-tin-sulfur-selenium and thin-film technology is applied in the direction of climate sustainability, photovoltaic power generation, sustainable manufacturing/processing, etc. It can solve the problems of unfavorable industrial production, flammability and explosion, and the introduction of chlorine, etc., and achieves strong practicability , low cost, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Clean the molybdenum foil, that is, the molybdenum foil is cleaned by electrodeposition in a mixed solution of concentrated sulfuric acid and methanol with a volume ratio of 1:7, and the molybdenum oxide on the surface of the molybdenum foil is etched away, and finally deionized Rinse with water and blow dry with nitrogen; the purity of the molybdenum foil used is 99.99%, the thickness is 0.02mm, and the area is 2cm×2cm;

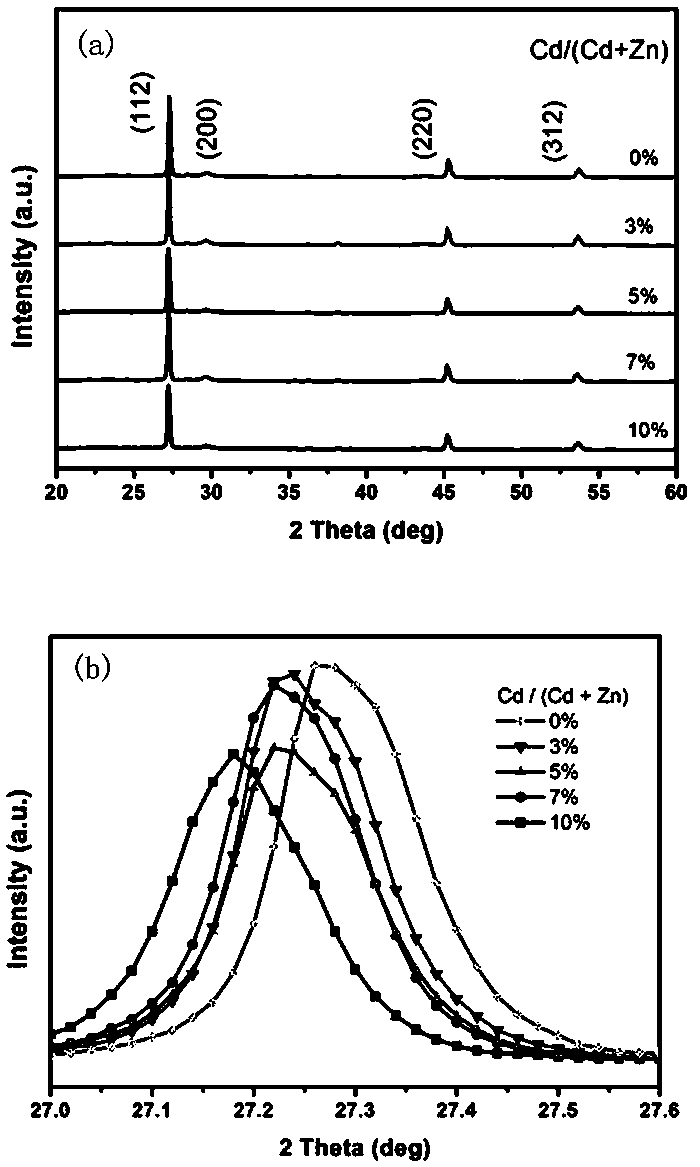

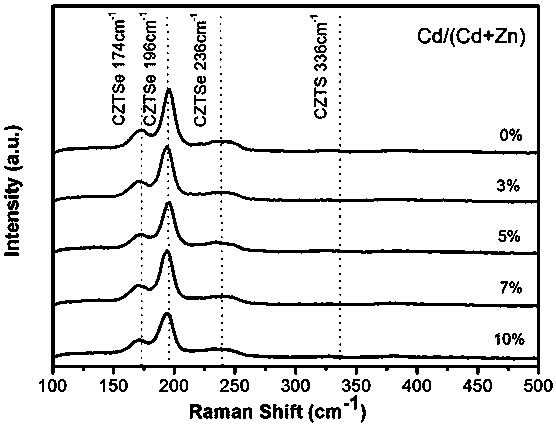

[0032] (2) Copper, zinc, tin, sulfur, and selenium films with different cadmium contents were prepared on flexible molybdenum substrates by the solution method of dissolving simple substances and post-selenization treatment;

[0033] The concrete steps of the solution method described in its step (2) are as follows:

[0034] A. After mixing elemental copper powder, zinc powder, cadmium powder, tin powder, sulfur powder and selenium powder in proportion, add them to ethylenediamine and ethanedithiol, heat and stir for 1.5 hours; the amount of cadmi...

Embodiment 2

[0045] (1) Cleaning the molybdenum foil: same as in Example 1;

[0046] (2) Copper, zinc, tin, sulfur, and selenium films with different cadmium contents were prepared on flexible molybdenum substrates by using the solution method to dissolve simple substances and post-selenization treatment: the same as in Example 1;

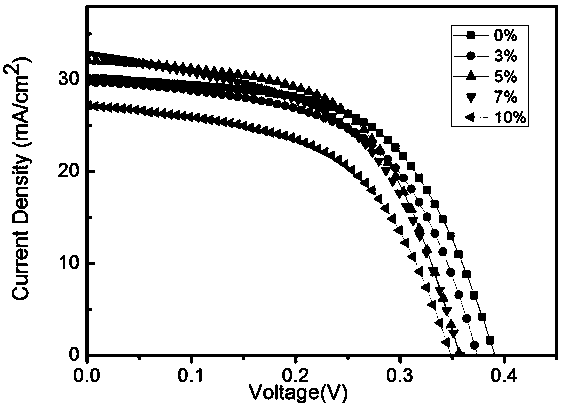

[0047] (3) Deposit a cadmium sulfide film on the surface of the cadmium-doped copper-zinc-tin-sulfur-selenium film obtained in (2) by using a chemical water bath method as a buffer layer, wherein the thickness of the cadmium sulfide film is 50nm;

[0048] (4) Deposit intrinsic zinc oxide (i-ZnO) film on the buffer layer obtained in (3) by sputtering method; where the sputtering gas is Ar, the pressure is 5mTorr, the power is 80W, and the time is 25min, the obtained i -ZnO film thickness is 50nm;

[0049] (5) Deposit an indium tin oxide (ITO) window layer on the i-ZnO film obtained in (4) by sputtering; the sputtering gas is Ar gas, the pressure is 1mTorr, the ...

Embodiment 3

[0054] (1) Cleaning the molybdenum foil: same as in Example 1;

[0055] (2) A cadmium-doped copper-zinc-tin-sulfur-selenium thin film with a band gap gradient was prepared on a flexible molybdenum substrate by using the solution method to dissolve the elemental substance and post-selenization treatment;

[0056] The concrete steps of the solution method described in its step (2) are as follows:

[0057] A. After mixing elemental copper powder, zinc powder, cadmium powder, tin powder, sulfur powder and selenium powder in proportion, add them to ethylenediamine and ethanedithiol, heat and stir for 1.5 hours; the amount of cadmium powder added Prepare two solutions according to the molar percentage of Cd / (Cd + Zn) being 3% and 10% respectively;

[0058] B. Add a certain proportion of stabilizers to the two solutions respectively, i.e. ethanolamine, thioglycolic acid, and ethylene glycol methyl ether are made into stabilizers according to the ratio of substances of 1:1:2. After...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical band gap | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com