Method for eliminating original grain boundary of nickel-based powder metallurgy superalloy

A nickel-based superalloy and superalloy technology, which is applied in the field of alloy materials, can solve the problems of grain growth, coarse grain structure, unsatisfactory structure conditions, etc., achieve fine and uniform grain size, and eliminate powder particle boundaries. , the effect of preventing excessive growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of the nickel-based powder superalloy described in this application is aimed at all nickel-based powder superalloys. As a preferred solution, the nickel-based powder superalloy includes: 13wt% to 30wt% of Co, 8wt% to 18wt% of Cr, 1wt% to 8wt% of Mo, 1wt% to 8wt% of W, 1wt% to 5wt% of Al, 1wt% to 5wt% of Ti and traces of C, B, Zr and Hf, and the balance is Ni; further, The nickel-based powder superalloy includes: 25wt% to 30wt% of Co, 10wt% to 15wt% of Cr, 3wt% to 6wt% of Mo, 3wt% to 6wt% of W, 2wt% to 4wt% of Al, 2wt% % to 4wt% of Ti, the content of C, B, Zr and Hf are independently greater than or equal to 0.02wt%, and the sum is less than or equal to 0.5wt%, and the balance is Ni. Further, in the nickel-based powder superalloy Containing trace elements: 0.05-0.25wt% of Hf, 0.02-0.1wt% of C, 0.02-0.09wt% of B, 0.02-0.8wt% of Zr, and the contents of other components are in the same range as above.

[0040] This application provides a method for e...

Embodiment 1

[0044] The main components of the nickel-based superalloy used in this embodiment are shown in Table 1,

[0045] Table 1 Composition Table of Alloy 1 (wt.%)

[0046]

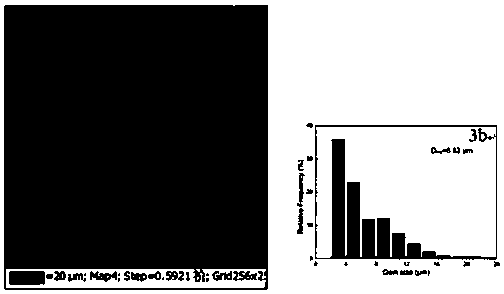

[0047] The nickel-based superalloy powder is prepared by argon atomization, and the nickel-based superalloy powder is sieved by a vibrating sieve to obtain a powder with a particle size range of -200 mesh. The powder is put into a bag, degassed and sealed. , and then put it into the hot isostatic pressing equipment to start hot isostatic pressing. The complete dissolution temperature of the γ' phase of the nickel-based superalloy in this embodiment is between 1140-1150 ° C. The hot isostatic pressing process system selected for this alloy is 1120℃ / 150MPa / 4h, that is, the hot isostatic pressing temperature is 1120℃, the hot isostatic pressing pressure is 150MPa, and the hot isostatic pressing holding time is 4h.

[0048] The microstructure of the nickel-based superalloy prepared by the above hot isostatic pre...

Embodiment 2

[0055] The main components of the nickel-based superalloy used in this embodiment are shown in Table 2,

[0056] Table 2 Composition Table of Alloy 2 (wt.%)

[0057]

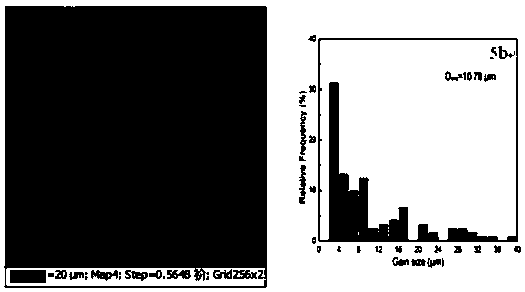

[0058] The nickel-based superalloy powder is prepared by the plasma rotating electrode method, and the superalloy powder is sieved by a vibrating sieve to obtain a uniform particle size range of -100 mesh to +270 mesh powder. Put the powder into the package, degas and seal, and then put it into the hot isostatic pressing equipment to start hot isostatic pressing. The complete dissolution temperature of the γ' phase of the nickel-based superalloy in this embodiment is between 1120-1130 °C During the period, the hot isostatic pressing process system selected for this alloy is 1100 ° C / 150 MPa / 4h, that is, the hot isostatic pressing temperature is 1100 ° C, the hot isostatic pressing pressure is 150 MPa, and the hot isostatic pressing holding time is 4 h.

[0059] The microstructure of the nickel-based supe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com