Ultralow-water-loss high-temperature-resistant solution-enriched lead-acid storage battery and preparation method thereof

A lead-acid battery, water loss technology, applied in the direction of lead-acid battery, lead-acid battery construction, battery electrodes, etc., can solve the problems of accelerated battery water loss, aggravated hydrolysis reaction, aggravated hydrolysis, etc., to reduce battery water loss, reduce Oxygen evolution potential and effect of reducing impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

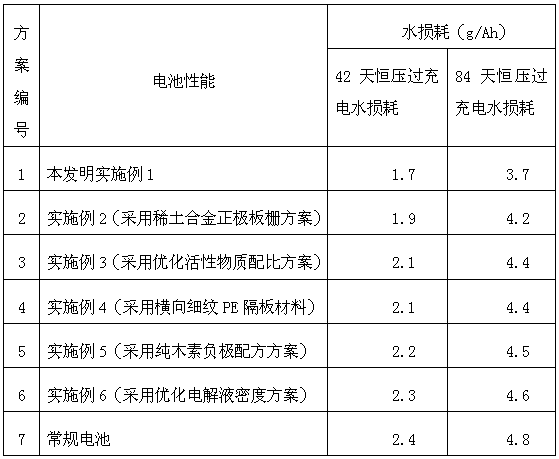

[0038] Example 1 (comprehensive plan):

[0039] Step 1. Grid alloy configuration:

[0040] Configuration of positive grid alloy: adopt Pb-Ca-Sn-Al alloy formula, add rare earth elements, specific configuration ratio: Pb balance; Ca: 0.01%; Sn: 1.52%; Al: 0.022%; rare earth element Ce: 0.1% , The anode alloy is configured with conventional anode alloy formulations.

[0041] Step 2. The preparation of positive and negative lead paste:

[0042] The positive electrode paste formula is made according to the conventional positive electrode paste formula;

[0043] The negative electrode formula contains the following ingredients in parts by weight:

[0044] Lead powder, 100 parts; short fiber, 0.05 parts; sulfuric acid 1.0 part; activated carbon 0.1 part; Norway lignin 0.15 parts, sulfuric acid 10 parts; deionized water 10 parts.

[0045] The lead powder is lead powder containing PbO, and the content of PbO is 76 wt%. The short fiber is made of polyester, and the length of the short fiber is 1...

Embodiment 2

[0055] Example 2 (A new type of rare earth alloy positive grid scheme is used alone):

[0056] Step 1. Grid alloy configuration:

[0057] Configuration of positive grid alloy: adopt Pb-Ca-Sn-Al alloy formula, add rare earth elements, specific configuration ratio: Pb balance; Ca: 0.01%; Sn: 1.52%; Al: 0.022%; rare earth element Ce: 0.1% , The anode alloy is configured with conventional anode alloy formulations.

[0058] Step 2. The preparation of positive and negative lead paste:

[0059] The positive and negative lead paste formula is according to the conventional positive and negative lead paste formula and process.

[0060] Step 3. Plate coating:

[0061] Fill the lead paste in a conventional way.

[0062] Step 4. Extreme group encapsulation:

[0063] Group and encapsulate the pole group according to the conventional PE separator and pole group encapsulation method.

[0064] Step 5. Battery formation and acid addition:

[0065] Carry out battery formation and acid addition in a convention...

Embodiment 3

[0067] Example 3 (Single use of optimized active material ratio scheme):

[0068] Step 1. Grid alloy configuration:

[0069] The positive and negative grid alloys are configured with conventional positive and negative alloy formulations.

[0070] Step 2. The preparation of positive and negative lead paste:

[0071] The positive and negative lead paste formula is according to the conventional positive and negative lead paste formula and process.

[0072] Step 3. Plate coating:

[0073] According to the positive and negative active material matching ratio of 1.20, the amount of paste for the positive and negative electrodes is designed, and the lead paste is filled by the wheel-type spreader of the extended mesh extension device.

[0074] Step 4. Extreme group encapsulation:

[0075] Group and encapsulate the pole group according to the conventional PE separator and pole group encapsulation method.

[0076] Step 5. Battery formation and acid addition:

[0077] Carry out battery formation and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com