Periosteum material with tissue oxygenation function as well as preparation method and application of periosteum material

A technology of periosteum and tissue, which is applied in the field of polylactic acid-glycolic acid copolymer PLGA particles, periosteum material and its preparation, and periosteum material prepared by electrospinning method. Slow speed and other problems, to achieve the effect of benefiting bone cell growth, simple process and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

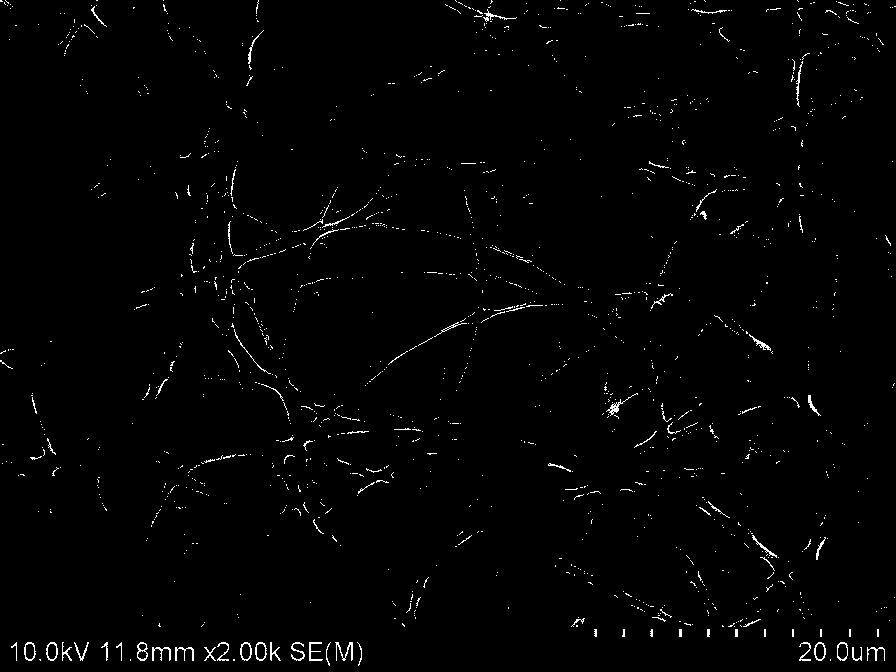

Image

Examples

Embodiment 1

[0026] 1. Preparation of PLGA-coated PFOB particles (PLGA-PFOB)

[0027] Dissolve 5 mg PLGA, 5 mg polylactic-co-glycolic acid-polyethylene glycol (PLGA-PEG), 200 μl Span 80 (S80) / dichloromethane (DCM) (3 / 17, volume ratio) in 200 μl DCM, then mixed with 2 ml of water, and 30 μl / ml of PFOB with a purity greater than 99% was added. Homogenize with a homogenizer for 1 min (ice bath), then sonicate for 3 min, 3 s and 10 s off, at 50% power. Homogenize with a homogenizer for 10 min (homogenize for 1 min and stop for 1 min) and then stir at room temperature for 3 h. Oxygenate the emulsion with medical oxygen for 10 minutes.

[0028] 2. Preparation of electrospinning solution

[0029] Add 0.6 g of poly(racemic lactic acid-caprolactone) copolymer (PDLLA-CL) to 10 ml of solvent dichloromethane: dimethylformamide (DMF) = 7:3 (V / V), stir magnetically at room temperature for 8 Hours; 2 ml of PLGA-PFOB solution was added thereto, and ultrasonication was performed for 10 minutes to obtai...

Embodiment 2

[0034] 1. Preparation of PLGA-coated PFOB particles (PLGA-PFOB)

[0035] Dissolve 1 mg PLGA, 1 mg polylactic-co-glycolic acid-polyethylene glycol (PLGA-PEG), 40 μl Span 80 (S80) / dichloromethane (DCM) (3 / 17, volume ratio) in 40 μl DCM, then mixed with 0.4 ml of water, and 20 μl / ml of PFOB with a purity greater than 99% was added. Homogenize with a homogenizer for 1 min (ice bath), then sonicate for 3 min, 3 s and 10 s off, at 50% power. Homogenize with a homogenizer for 10 min (homogenize for 1 min and stop for 1 min) and then stir at room temperature for 3 h. Oxygenate the emulsion with medical oxygen for 5 minutes.

[0036] 2. Preparation of electrospinning solution

[0037] Add 0.3 g of poly(racemic lactic acid-caprolactone) copolymer (PDLLA-CL) to 5 ml of solvent dichloromethane: dimethylformamide (DMF) = 7:3 (V / V), stir magnetically at room temperature 10 hours; 0.5 ml of PLGA-PFOB solution was added thereto and ultrasonicated for 10 minutes to obtain a spinning soluti...

Embodiment 3

[0041] 1. Preparation of PLGA-coated PFOB particles (PLGA-PFOB)

[0042] Dissolve 5 mg PLGA, 5 mg polylactic-co-glycolic acid-polyethylene glycol (PLGA-PEG), 200 μl Span 80 (S80) / dichloromethane (DCM) (3 / 17, volume ratio) in 200 μl DCM, then mixed with 2 ml of water, and 150 μl / ml of PFOB with a purity greater than 99% was added. Homogenize with a homogenizer for 1 min (ice bath), then sonicate for 3 min, 3 s and 10 s off, at 50% power. Homogenize with a homogenizer for 10 min (homogenize for 1 min and stop for 1 min) and then stir at room temperature for 3 h. Oxygenate the emulsion with medical oxygen for 10 minutes.

[0043] 2. Preparation of electrospinning solution

[0044] Add 0.6 g of poly(racemic lactic acid-caprolactone) copolymer (PDLLA-CL) to 10 ml of solvent dichloromethane: dimethylformamide (DMF) = 7:3 (V / V), stir magnetically at room temperature for 7 Hours; 3 ml of PLGA-PFOB solution was added thereto, and ultrasonication was performed for 10 minutes to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com